High-capacity medium-temperature phase-change heat storage and heat release system for thermal power plant and heat storage and heat release method of system

A phase-change heat storage and large-capacity technology, which is applied in the field of heat storage systems, can solve problems such as temperature inconsistency between the inlet and outlet of the heat storage device, high finished product, difficult transportation, etc., to achieve uniform melting or solidification, and a safe and reliable structure Sexual improvement, good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

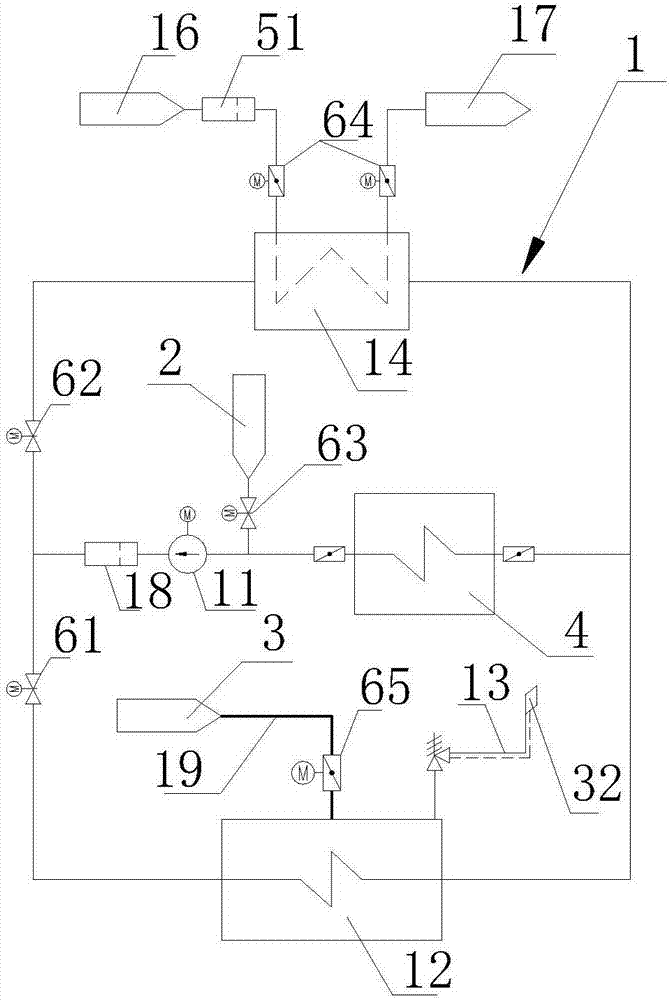

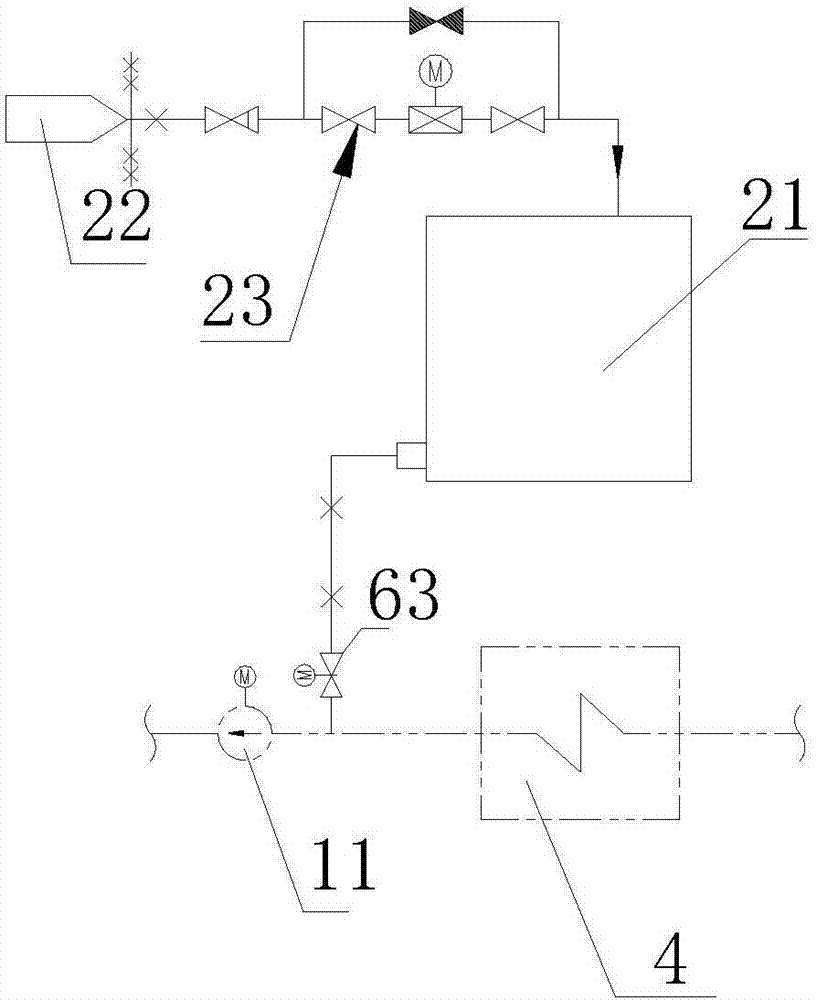

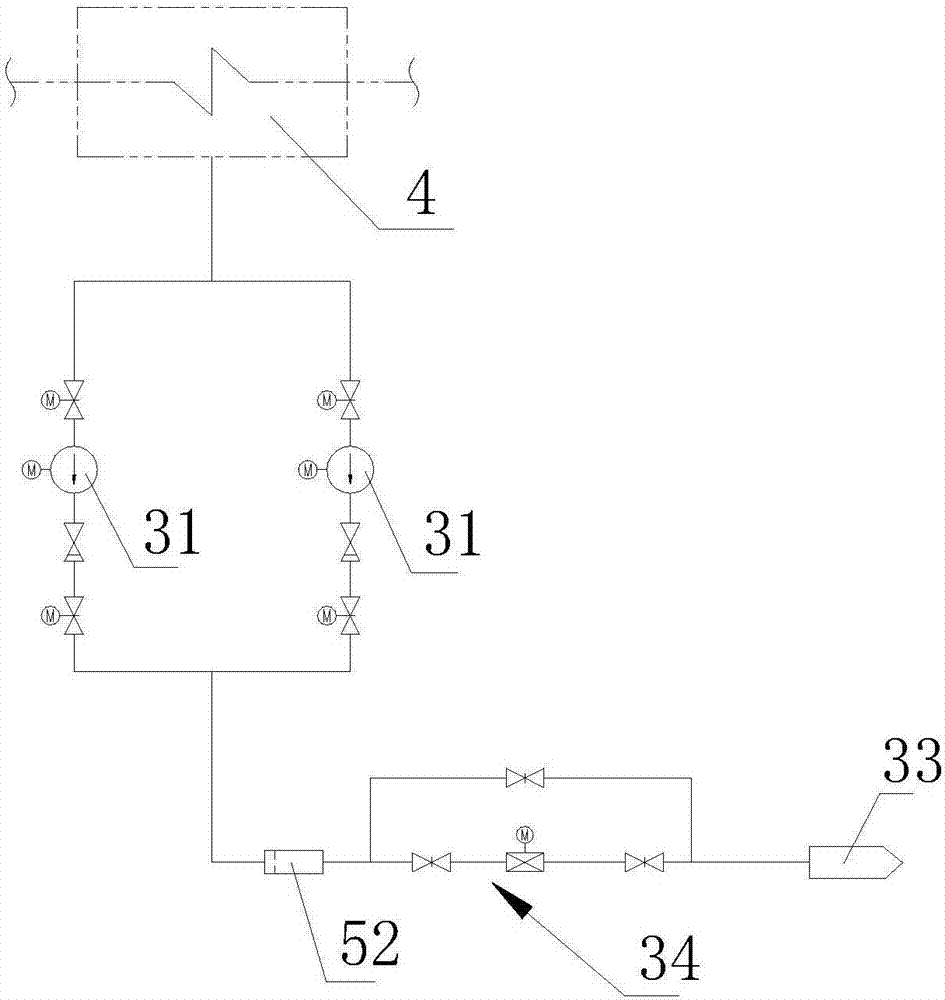

[0024] Referring to the accompanying drawings, it can be seen that the large-capacity medium-temperature phase-change heat storage and release system of a thermal power plant is characterized in that it includes a closed circulation system 1 for heat storage and heat release, and a constant pressure for stabilizing the medium pressure in the closed circulation system 1 System 2, and a hydrophobic system 3 for collecting the hydrophobic in the closed circulation system 1;

[0025] The closed circulation system 1 comprises a closed circulation pump 11, a heat storage heater 12, a heat storage device 4 and an exothermic cooler 14, the output e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com