A hydraulic cylinder piston rod seal wear compensation monitoring device

A wear compensation and monitoring device technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc., can solve problems affecting the working efficiency of hydraulic cylinders, lack of monitoring of wear status, and wear of sealing contact parts. Achieve good anti-wear performance, prolong service life and improve sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

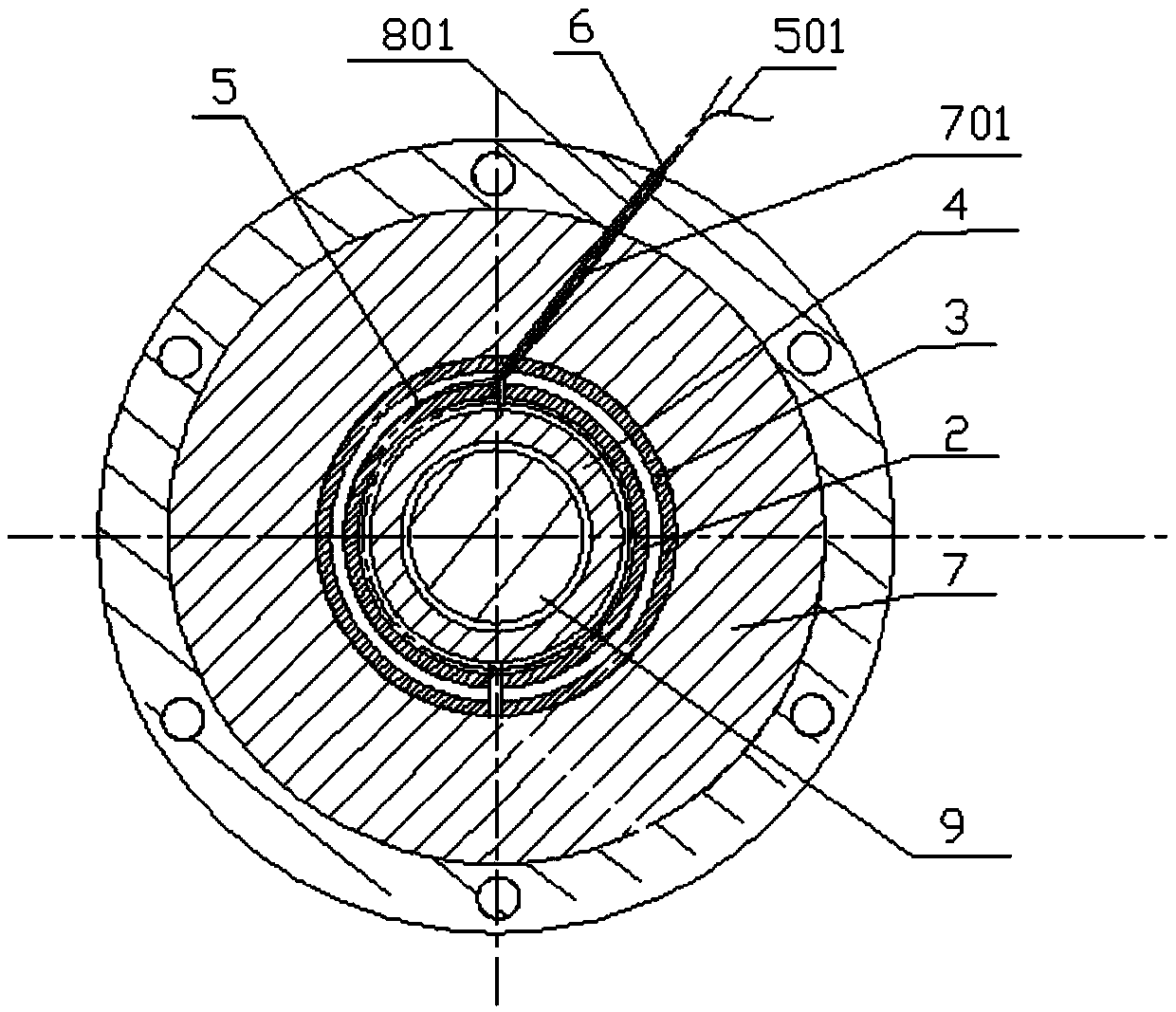

[0038] The hydraulic cylinder piston rod seal wear compensation monitoring device provided by the present invention mainly consists of an inner positioning sleeve 2, an outer positioning sleeve 3, a Y-shaped sealing ring 4 with an inner cavity, a fiber grating sensor 5, a telescopic hose 6, and a guiding positioning sleeve 7 , Cylinder barrel 8, flange 10, cylinder bottom 11, dustproof sealing ring 12, left sealing positioning ring 15, fiber grating demodulator 21, industrial computer 22, board card 23 is formed.

[0039] The inner positioning sleeve 2 and the outer positioning sleeve 3 are connected through the positioning pin 19 of the inner positioning sleeve to ensure that the oil port 203 of the inner positioning sleeve communicates with the oil port 302 of the outer positioning sleeve. The positioning pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com