Draining pump rotor starting mechanism, draining pump motor and draining pump

A technology of starting mechanism and drainage pump, applied in electromechanical devices, machines/engines, liquid fuel engines, etc., can solve noise, poor concentricity between rotor bushing x23 and injection core x21, rotor starting mechanism x2 starting performance limitation, etc. problems, to achieve the effect of enhancing concentricity, improving starting performance, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

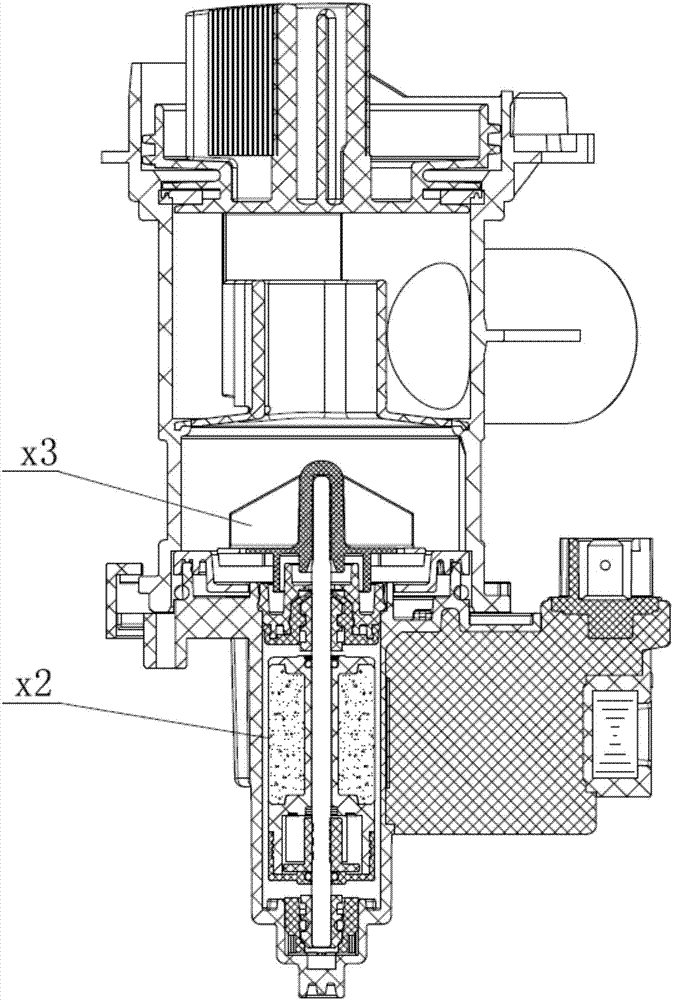

[0039] The invention provides a drainage pump, which includes a pump body, a pump cover assembly sealingly connected with the pump body, a drainage pump motor, and an impeller. The drainage pump motor includes a plastic-encapsulated coil, a stator core and other related components arranged outside the pump body, and a drainage pump rotor starting mechanism arranged in the pump body and coaxially connected with the impeller. Because in the present invention, only the drainage pump rotor starting mechanism in the drainage pump motor is improved, and other structures in the drainage pump except the drainage pump rotor starting mechanism are the same as the corresponding structures in the prior art drainage pump, so in The structure of other parts of the drainage pump except the rotor starting mechanism of the drainage pump will not be described in detail.

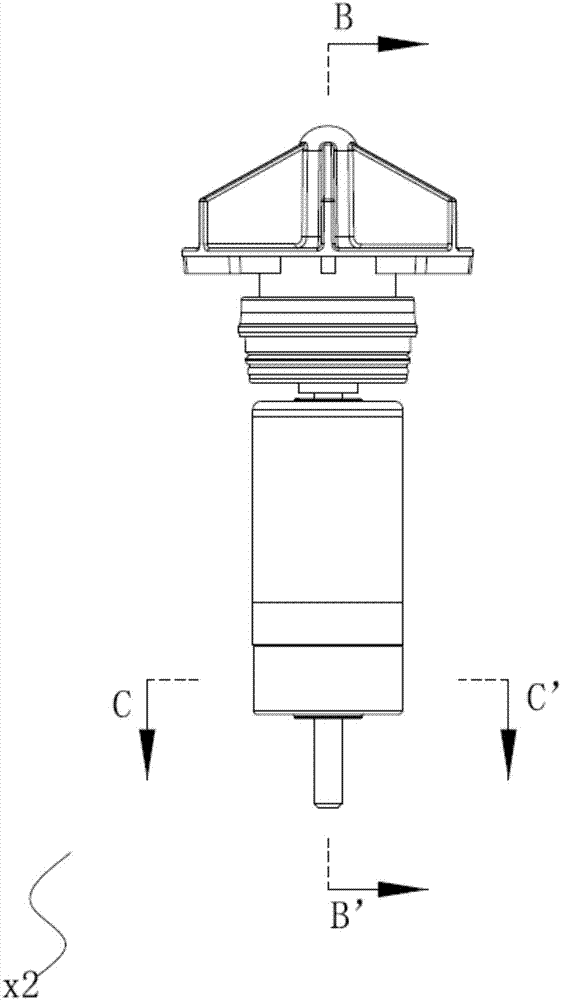

[0040] see Figure 8 ~ Figure 10 Specifically, the drainage pump rotor starting mechanism 2 includes a magnetic core 21 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com