A method for energy-saving transformation of oil-injected screw air compressor stations in power plants

An energy-saving transformation, air compressor technology, applied in mechanical equipment, machinery/engine, pump combination for elastic fluid rotary piston type/oscillating piston type, etc. energy consumption, low utilization rate of air compressors, etc., to achieve good energy-saving effect, reduce labor costs, and reduce the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

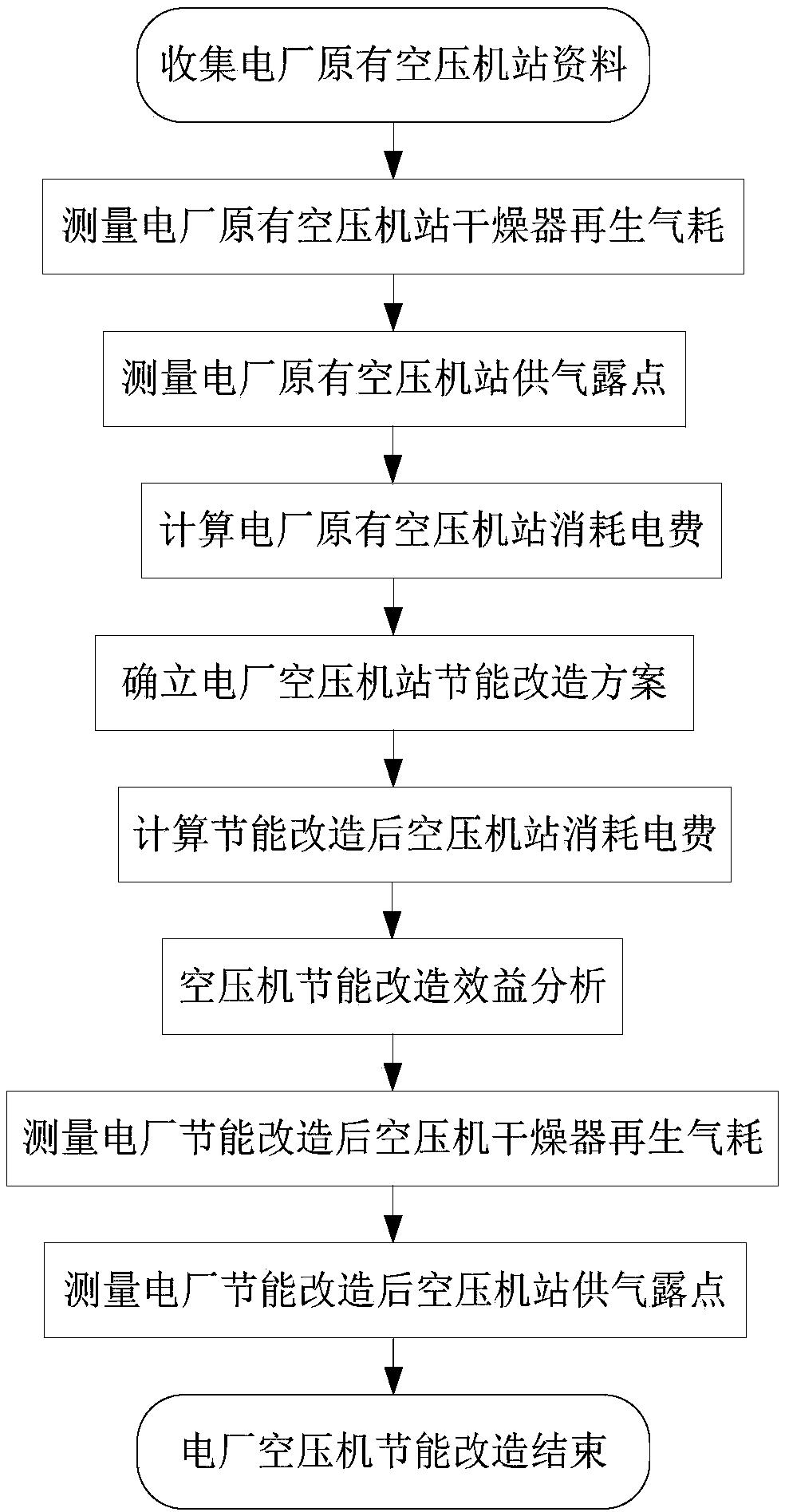

[0047] Such as figure 1 As shown, a power plant oil injection screw type air compressor station energy-saving transformation method according to the present invention comprises the following steps:

[0048] 1) Collect the original data of the original air compressor station in the power plant, and enter step 2 after the collection is completed;

[0049] 2) Measure the desiccant regeneration gas consumption of the original air compressor station in the power plant, and enter step 3);

[0050] 3) Measure the air supply dew point of the original air compressor station of the power plant, and enter step 4);

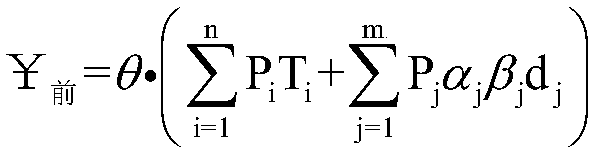

[0051] 4) Calculate the electricity consumption fee of the original air compressor station of the power plant, and enter step 5);

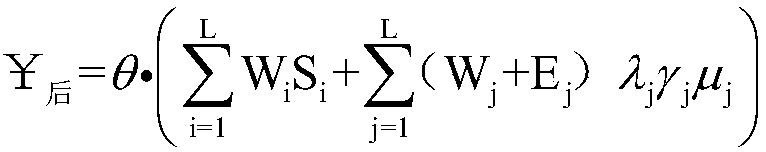

[0052] 5) Establish the energy-saving transformation plan for the air compressor s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com