Gear double-spiral-type fluid viscous damper

A viscous damper, screw-type technology, applied in protective buildings/shelters, building components, earthquake resistance, etc., can solve the problem of less application of wall-type viscous dampers, low cost of metal mild steel dampers, and difficulty in manufacturing , cost increase and other issues, to achieve the effect of convenient daily maintenance and repair, convenient repair and replacement, and large adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

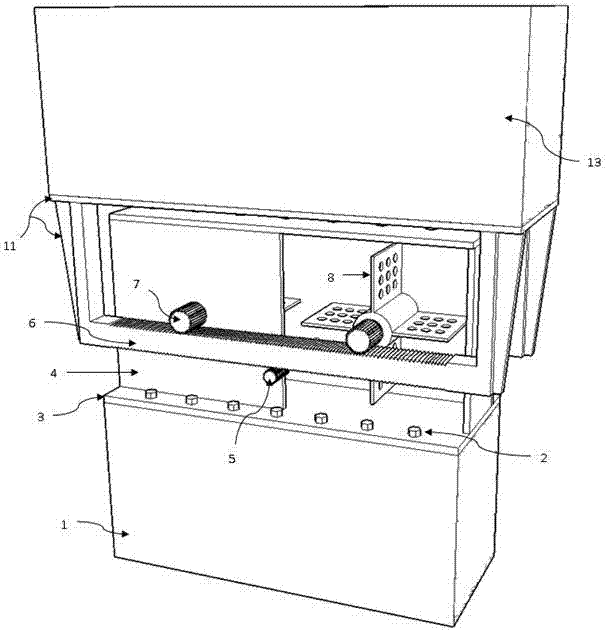

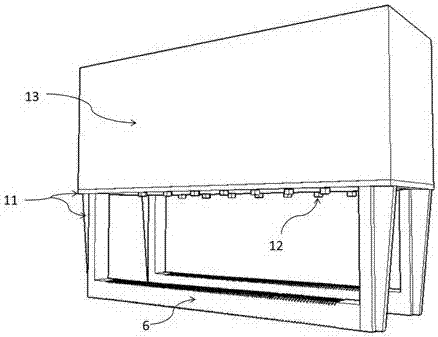

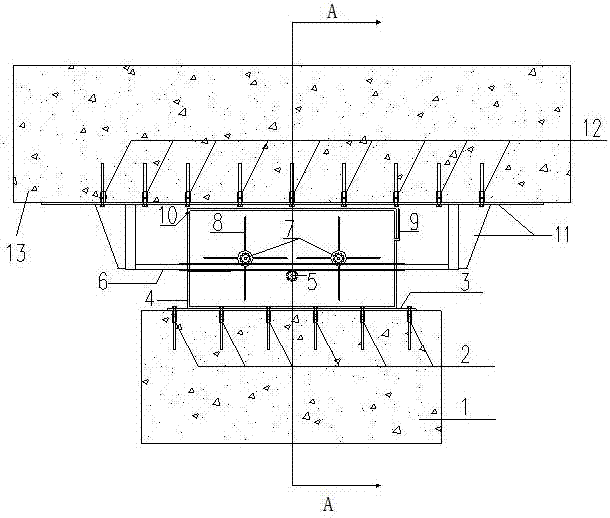

[0019] Embodiment 1: as Figure 1-4 As shown, a gear double-helical viscous damper includes a lower concrete connecting wall 1, a lower sleeve-type connecting piece 2, a lower connecting plate 3, a viscous liquid tank 4, a stable gear shaft 5, and a double-sided gear transmission rod 6. Helical gear shaft 7, energy-dissipating blade 8, connector inspection window 9, viscous liquid filling port 10, upper connector 11, upper sleeve connector 12 and upper concrete connecting wall 13;

[0020] The bottom end of the lower connecting plate 3 is connected to the top end of the lower concrete connecting wall 1 through the lower sleeve-type connecting piece 2, and the top end of the lower connecting plate 3 of the damper is welded with a steel plate with a viscous liquid filling port 10 and a connector The inspection window 9 and the bottom of the viscous liquid tank 4 that is full of viscous liquid are closely connected, and a helical gear shaft 7 and a stabilizing gear shaft 5 are re...

Embodiment 2

[0023] Embodiment 2: as Figure 1-4 As shown, a gear double-helical viscous damper includes a lower concrete connecting wall 1, a lower sleeve-type connecting piece 2, a lower connecting plate 3, a viscous liquid tank 4, a stable gear shaft 5, and a double-sided gear transmission rod 6. Helical gear shaft 7, energy-dissipating blade 8, connector inspection window 9, viscous liquid filling port 10, upper connector 11, upper sleeve connector 12 and upper concrete connecting wall 13;

[0024] The bottom end of the lower connecting plate 3 is connected to the top end of the lower concrete connecting wall 1 through the lower sleeve-type connecting piece 2, and the top end of the lower connecting plate 3 of the damper is welded with a steel plate with a viscous liquid filling port 10 and a connector The inspection window 9 and the bottom of the viscous liquid tank 4 filled with viscous liquid are closely connected. Two helical gear shafts 7 and a stable gear shaft 5 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com