Anode guide rod assembly and manufacturing method thereof

A technology of an anode guide rod and a manufacturing method, which is applied in the field of aluminum smelting, can solve the problems of cracking of explosive discs, large maintenance amount, and high maintenance cost, and achieve the effects of tighter and firmer connections, improved production yield, and reduced inspection personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

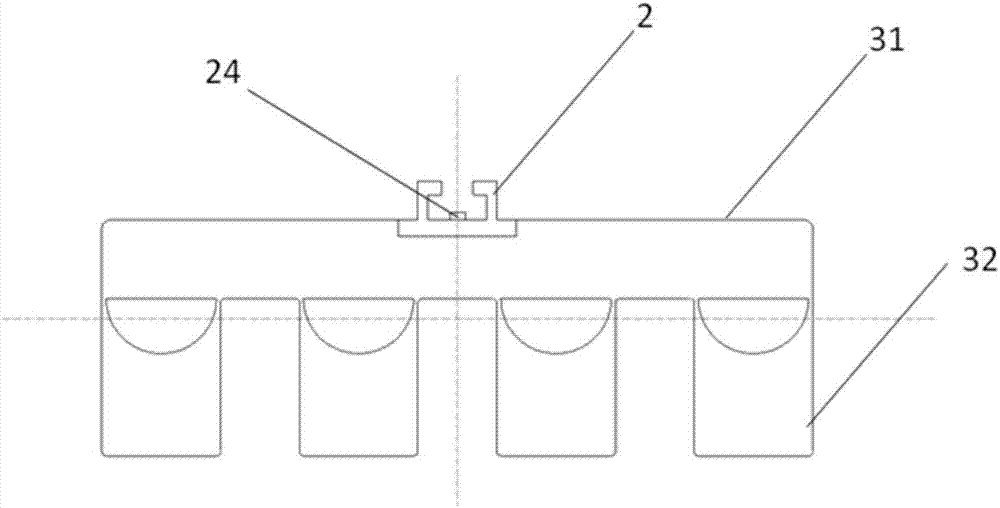

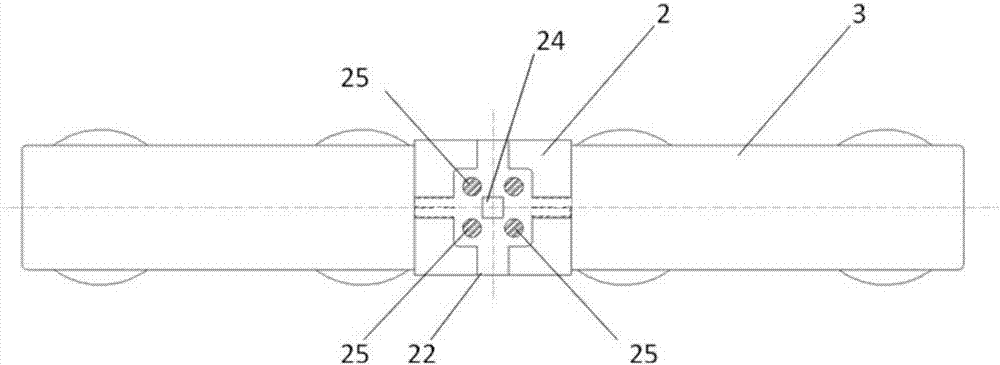

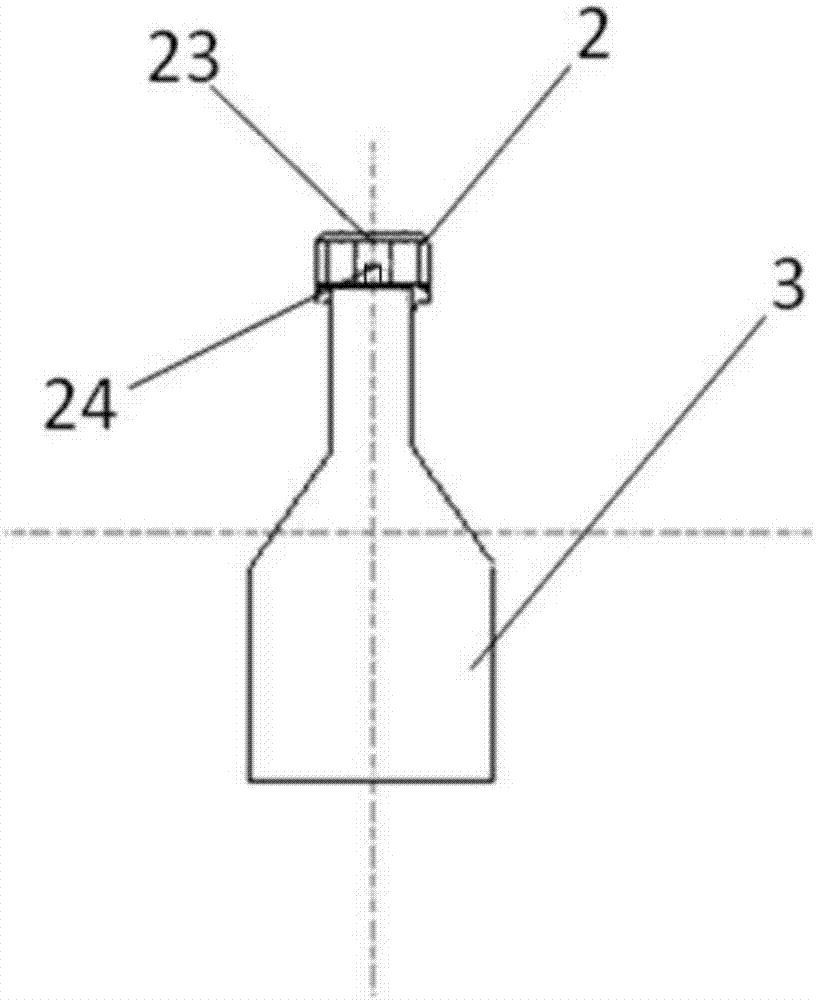

[0056] Such as Figure 1-7 As shown, an anode guide rod assembly includes an anode guide rod 1, a connector 2 and a steel claw assembly 3; the bottom of the connector 2 is fixedly connected to the upper part of the steel claw assembly 3, and the fixed connection method can be that the connector 2 It is integrally cast with the steel claw assembly 3, and the connecting piece 2 and the steel claw assembly 3 can also be welded together; It is located in the trough structure 21 and connected with the trough structure 21 by casting. In specific use, the connecting piece 2 can be made of steel; the anode guide rod 1 is an aluminum anode guide rod; the casting solution used during casting can be aluminum solution. In a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com