A method for transforming and extracting resveratrol using bacteria

A technology of resveratrol and bacteria, applied in the field of bacterial transformation and extraction of resveratrol, can solve the problems of large amount of solvent, high production cost, non-renewable and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

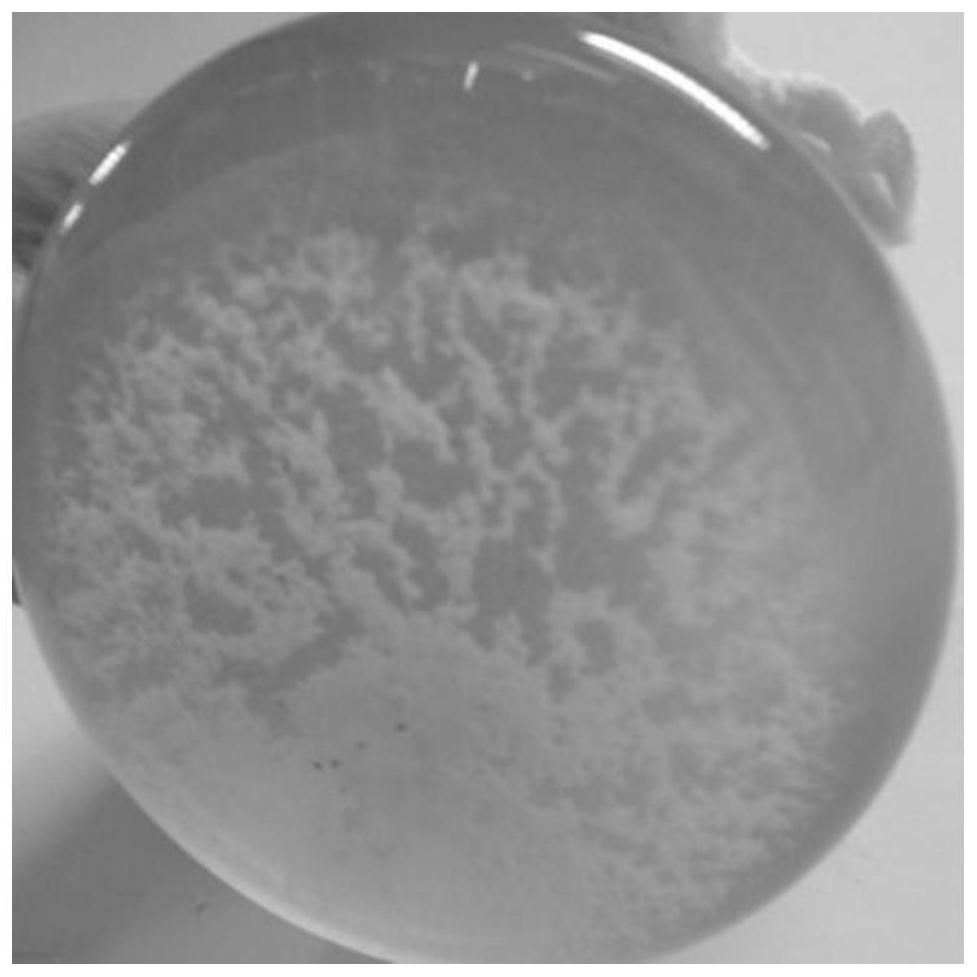

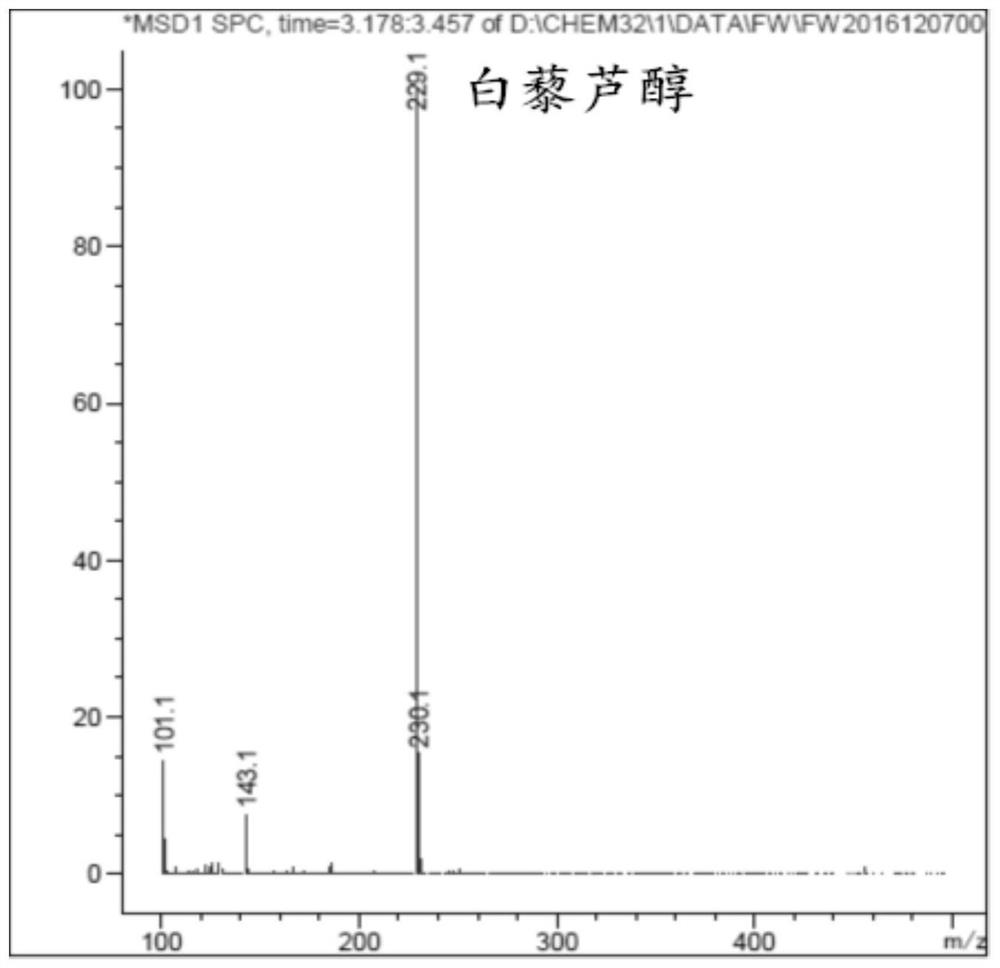

Image

Examples

Embodiment 1

[0027] Add 0.1% substrate Polygonum cuspidatum crude medicinal material to the culture medium (pH=7.0), insert 1% Bacillus shamford seed solution (OD 600nm =1.0), at 37°C, 200r / min, shake flask fermentation for 10h, and the product has been precipitated. Centrifuge at 5000r / min, 4°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add 100% ethanol to the precipitate, and centrifuge again at 5000r / min, 4°C, Discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.3%.

Embodiment 2

[0029] Add 0.3% substrate Polygonum cuspidatum crude drug into the culture medium (pH=7.0), insert 3% Bacillus shamfu seed solution (OD 600nm =0.8), at 28°C, 180r / min shake flask fermentation for 12h, product was precipitated. Centrifuge at 2000r / min, 25°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add ethanol with a purity of 80% to the precipitate, and centrifuge again at 2000r / min, 25°C , discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.3%.

Embodiment 3

[0031] Add 0.1% substrate Polygonum cuspidatum crude medicinal material into the culture medium (pH=5.0), insert 3% Bacillus shamford seed solution (OD 600nm =0.8), at 37°C, 200r / min shake flask fermentation for 6h, product was precipitated. Centrifuge at 3000r / min, 25°C, discard the supernatant; wash the precipitate with water, centrifuge to remove the supernatant; add methanol with a purity of 90% to the precipitate, and centrifuge again at 3000r / min, 25°C , discard the precipitate; evaporate the organic solvent in the supernatant to obtain the resveratrol product with a purity of 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com