Oil field sludge treatment method

A technology for oilfield sludge and treatment methods, which is applied in sludge treatment, water/sludge/sewage treatment, pyrolysis treatment of sludge, etc. It can solve the problems of high treatment cost and frequent process flow, and achieve the reduction of thermal analysis temperature , Improve the removal efficiency, improve the effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

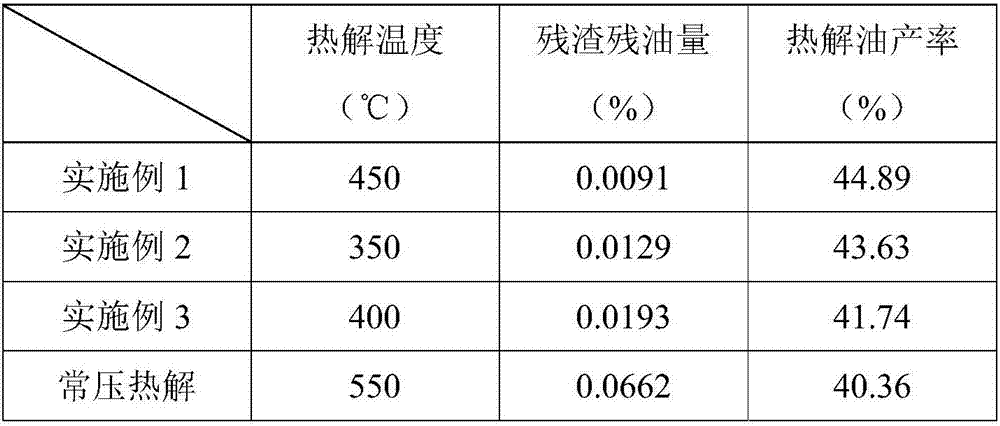

Embodiment 1

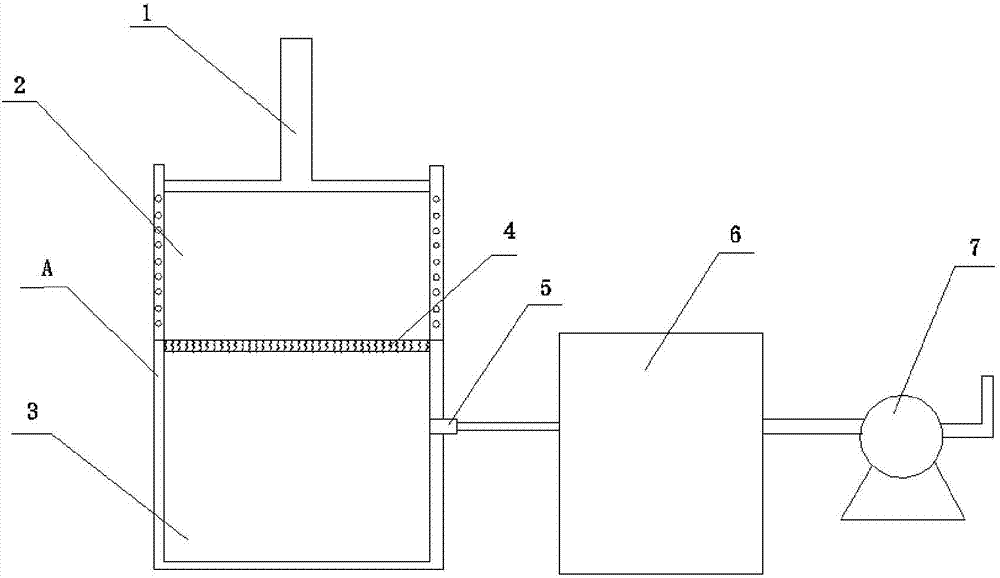

[0027] 1. Take 10kg oilfield sludge, and make 200g specific surface area 360m 2 / g, activated alumina particles with a specification of Φ8-10 are added to the oilfield sludge; after mixing and stirring evenly, the oilfield sludge mixture is obtained;

[0028] 2. Put the oilfield sludge mixture into the pyrolyzer with heating device of the vacuum desorption device. The compression device on the upper part of the desorber of the device pressurizes the desorber vertically downward, applying a pressure of 20Mpa, and the water in the oilfield sludge flows out through the sieve plate at the lower part of the desorber with a heating device and enters the liquid collection tank. The organic matter in the sludge is pyrolyzed and removed under the action of heating and extrusion, and enters the condensing device for recovery to obtain pyrolysis oil;

[0029] 3. The gas recovered and treated by the condensing device is sent into the atmosphere through a vacuum pump; the dried residue af...

Embodiment 2

[0031] 1. Take 10kg oilfield sludge, and make 200g specific surface area 360m 2 / g, activated alumina particles with a specification of Φ8-10 are added to the oilfield sludge; after mixing and stirring evenly, the oilfield sludge mixture is obtained;

[0032] 2. Put the oilfield sludge mixture into the pyrolyzer with heating device of the vacuum desorption device. The compression device on the upper part of the desorber of the device pressurizes the desorber vertically downward, applying a pressure of 10Mpa, and the water in the oilfield sludge flows out through the sieve plate at the lower part of the desorber with a heating device and enters the liquid collection tank. The organic matter in the sludge is pyrolyzed and removed under the action of heating and extrusion, and enters the condensing device for recovery to obtain pyrolysis oil;

[0033] 3. The gas recovered and treated by the condensing device is sent into the atmosphere through a vacuum pump; the dried residue af...

Embodiment 3

[0035] 1. Take 10kg oilfield sludge, and make 200g specific surface area 360m 2 / g, activated alumina particles with a specification of Φ8-10 are added to the oilfield sludge; after mixing and stirring evenly, the oilfield sludge mixture is obtained;

[0036] 2. Put the oilfield sludge mixture into the pyrolyzer with heating device of the vacuum desorption device. The compression device on the upper part of the desorber of the device pressurizes the desorber vertically downward, applying a pressure of 15Mpa, and the water in the oilfield sludge flows out through the sieve plate at the lower part of the desorber with a heating device and enters the liquid collection tank. The organic matter in the sludge is pyrolyzed and removed under the action of heating and extrusion, and enters the condensing device for recovery to obtain pyrolysis oil;

[0037] 3. The gas recovered and treated by the condensing device is sent into the atmosphere through a vacuum pump; the dried residue af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com