Detection and replacement method for battery of electric bus

An electric bus and battery detection technology, which is applied in electric vehicles, electric power devices, battery/fuel cell control devices, etc., can solve the problems of large demand for backup batteries, high cost, and low battery utilization, and improve the use efficiency , reduce the quantity, save battery purchases and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

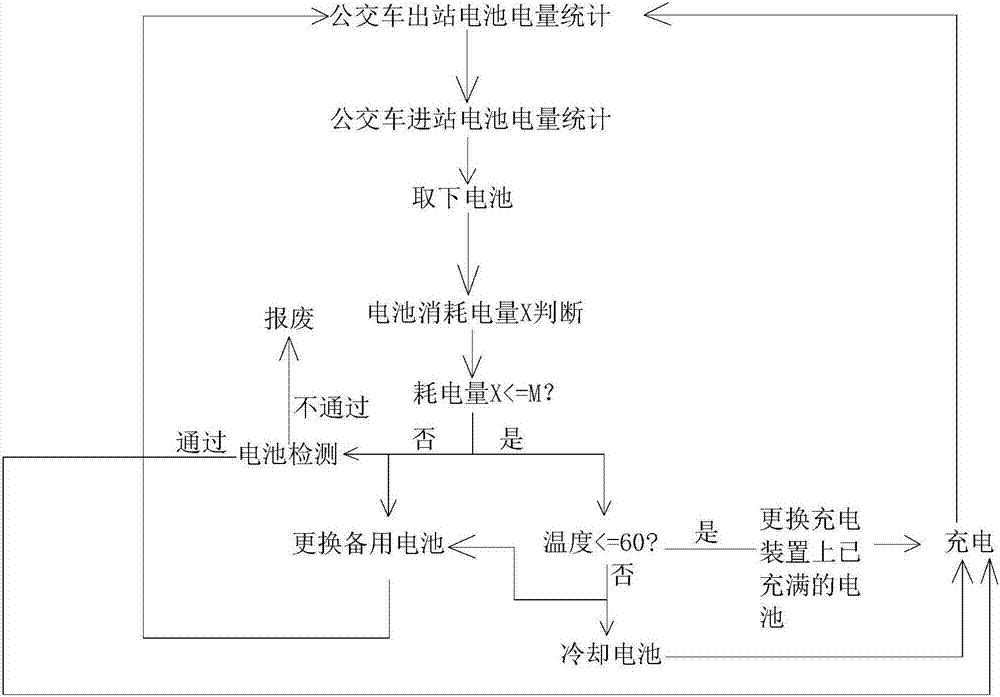

[0013] Combine below figure 1 , to further describe the present invention.

[0014] A battery detection and replacement method for an electric bus, comprising the following steps:

[0015] (A) More than two charging devices are installed in the battery-changing station of the electric bus. The battery-changing station is set in a certain return yard at the end of the bus route, and each charging device has a set charging current and charging voltage, namely Each charging device can adjust the charging amount q per unit time within the set range;

[0016] (B) When each bus leaves the station, it detects the battery power and automatically records it in the computer. When the bus enters the power station again after driving a round trip, the battery power is detected and Comparing the computer with the battery power when it left the station last time, it can calculate the power consumption X during a round-trip driving process, and the time T from the last time it left the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com