Novel high polymer material mixing and stirring machine

A polymer material and mixing machine technology, which is applied in the field of new polymer material mixing and mixing machine, can solve the problems of dust and waste gas escaping, high power consumption, environmental impact, etc., and achieves obvious environmental protection effect and energy saving. Consume and overcome the effect of dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

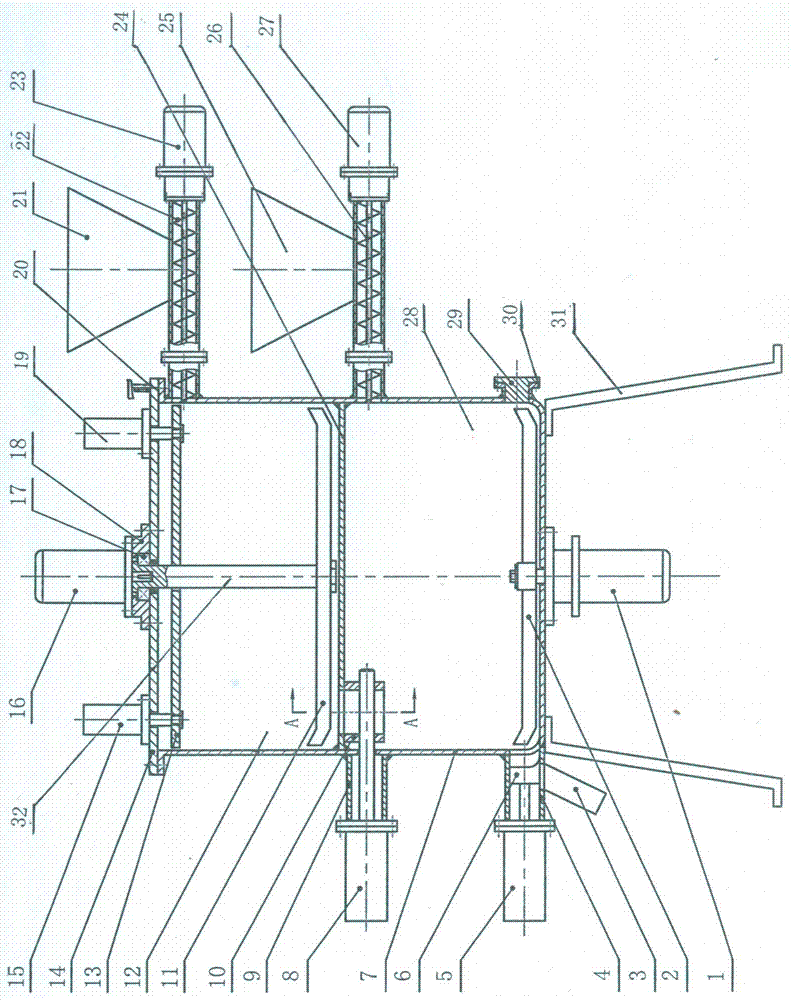

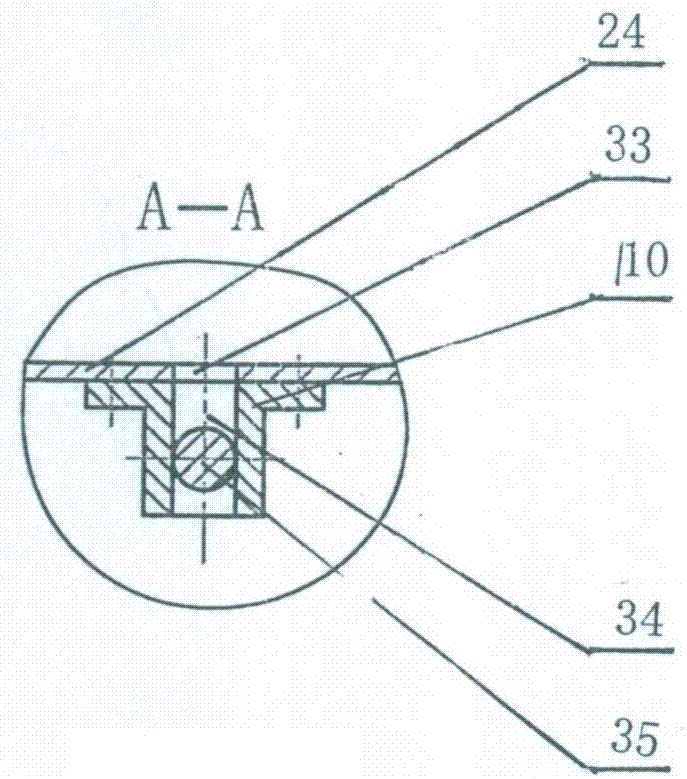

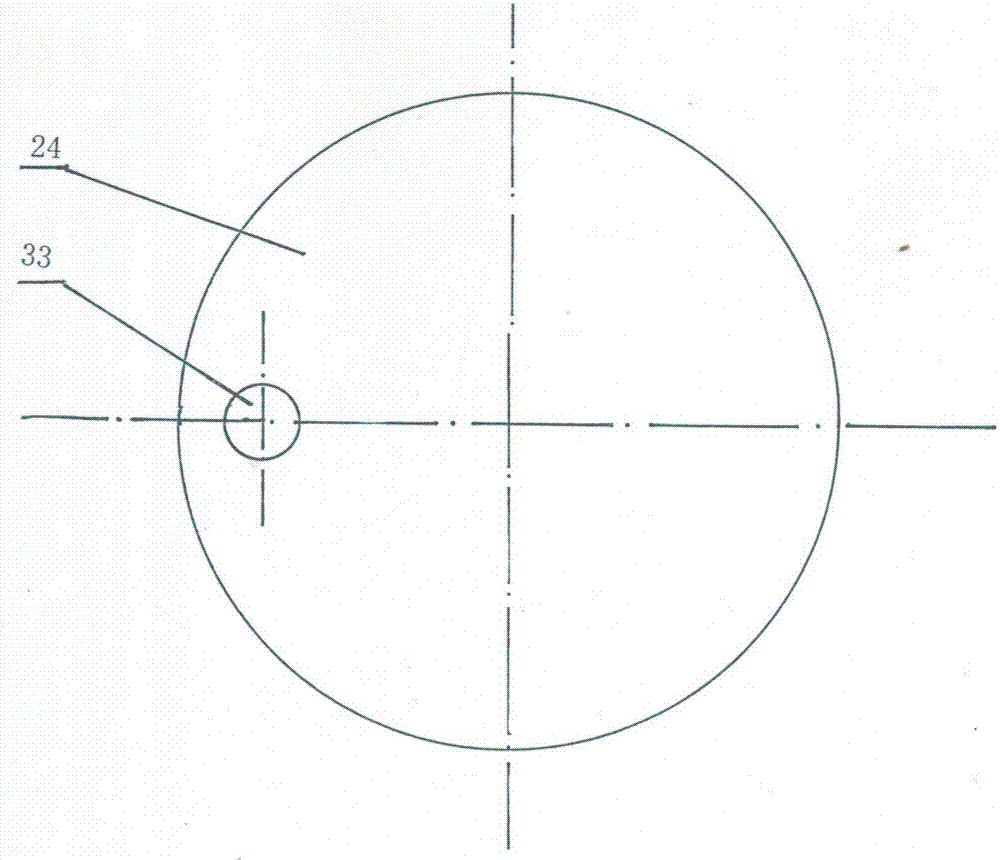

[0017] The design scheme of the present invention will be further described below in conjunction with the embodiments of the accompanying drawings of the description. The embodiments in the accompanying drawings of the description are a new type of polymer material mixing mixer of the present invention.

[0018] Figure 1-3 Shown, a kind of novel polymer material mixing mixer of the present invention, this mixing mixer comprises mixing tank 7, mixing tank support 31, and mixing tank 7 inner cavity is provided with upper mixing chamber 12 and lower mixing tank The feed bin 28 is provided with a high-speed stirring paddle 11, a stirring shaft 32, and a pressure plate 13 in the inner cavity of the upper mixing bin 12, and a mixing tank cover 14 is provided at the upper port of the upper mixing tank 12, and the mixing tank cover 14 is fixed together by the screw 20 and the mixing tank 7, and the motor 16, the bearing 17, the bearing seat 18, the third cylinder 15, the fourth cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com