Honing machine grinding head driving mechanism

A technology of driving mechanism and honing machine, which is applied in the direction of honing machine tools, grinding drive devices, and parts of grinding machine tools, etc., which can solve problems affecting processing efficiency and processing accuracy, so as to improve honing efficiency, ensure grinding quality, and reduce friction. force reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

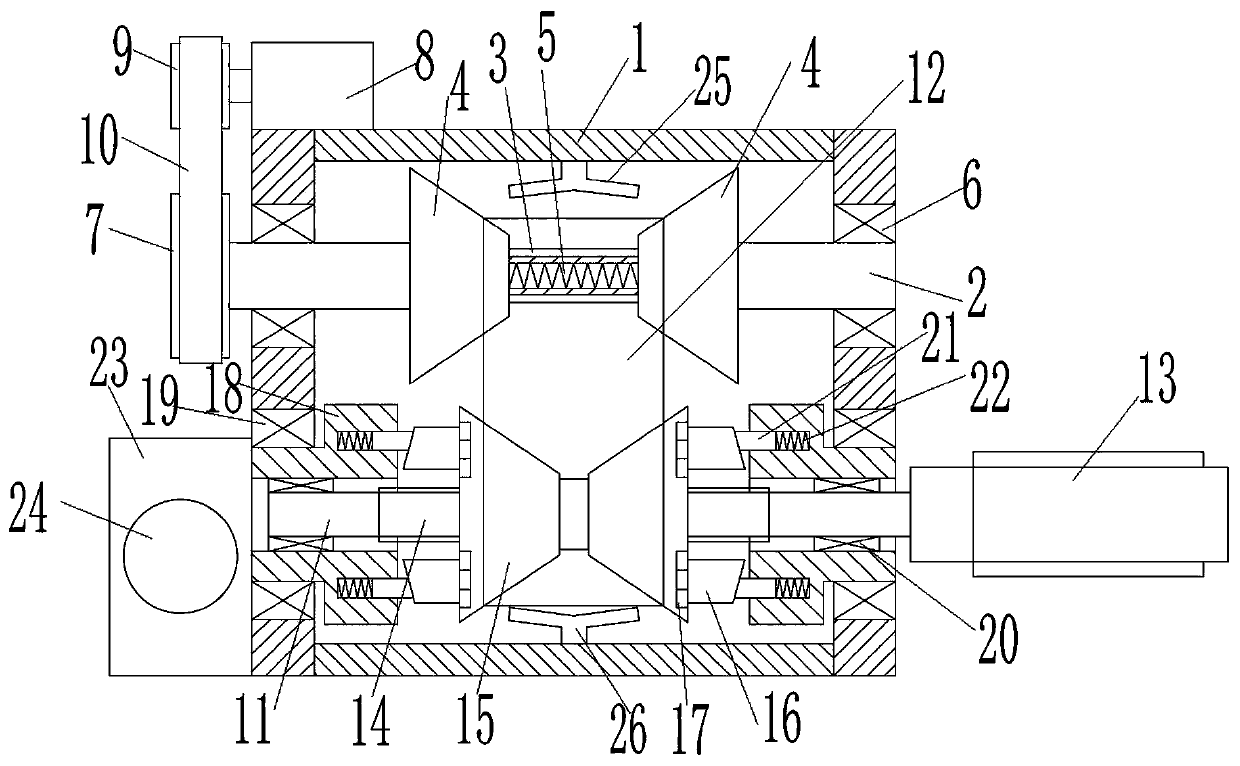

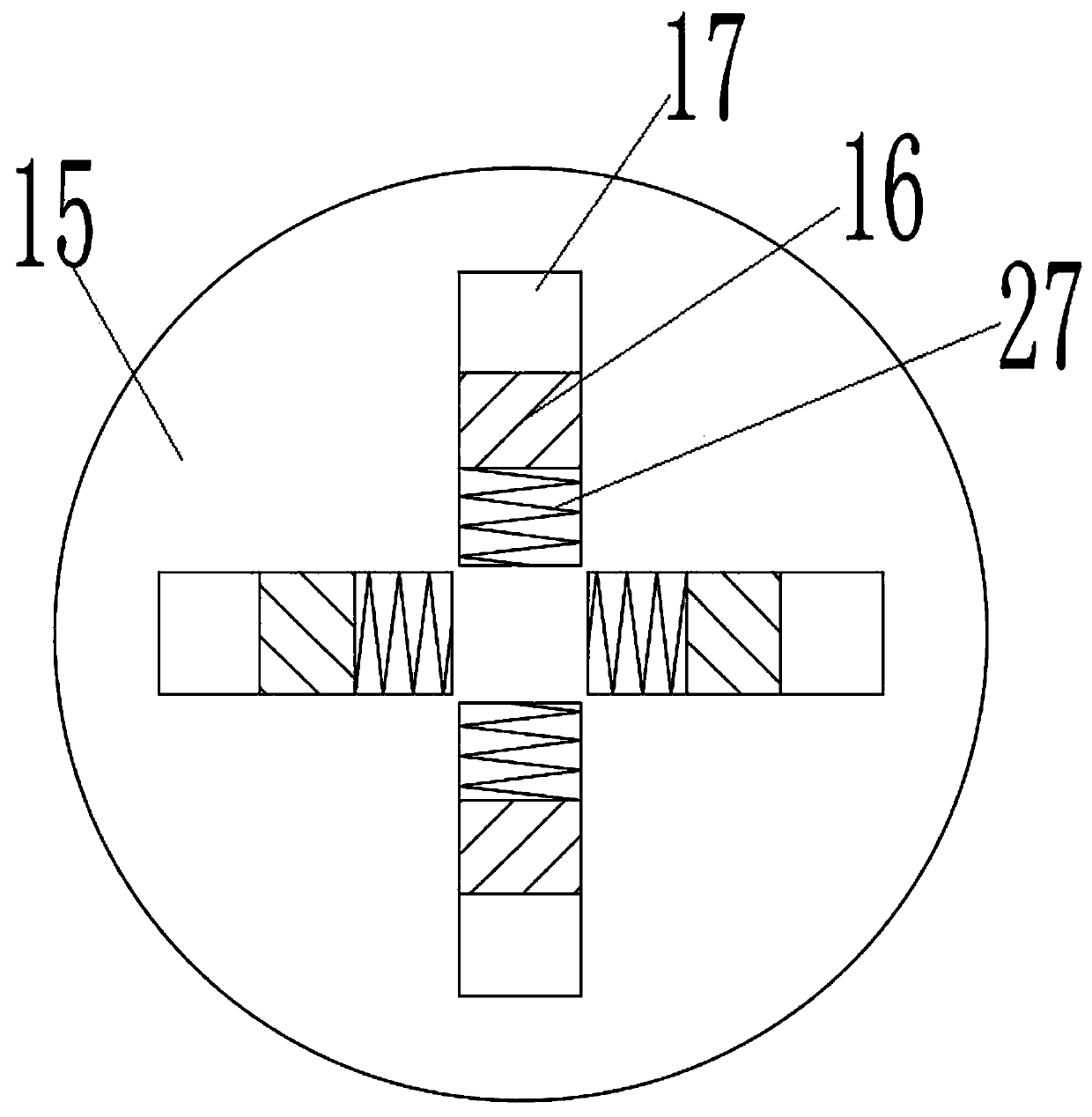

[0014] Attached below figure 1 , attached figure 2 The present invention will be further described.

[0015] A grinding head driving mechanism of a honing machine, comprising: a transmission box 1; a main shaft 2 and a driven shaft 11, the two ends of the main shaft 2 are horizontally installed in the transmission box 1 through bearings Ⅰ and 6 respectively, and the two ends of the driven shaft 11 are respectively passed through the bearings Ⅲ 20 is horizontally installed in the transmission box 1, the middle part of the main shaft 2 is provided with a spline shaft I 3, and the middle part of the driven shaft 11 is provided with a spline shaft II 14; the motor 8 is installed on the transmission box 1, and the motor 8 The output shaft of the output shaft is connected with the main shaft 2 through the transmission mechanism; two driving cone wheels 4 are arranged oppositely, and the two driving cone wheels 4 are respectively slidably installed on the spline shaft I 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com