A kind of molten magnesium casting holding furnace

A holding furnace and molten magnesium technology, which is applied in casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of untimely adding molten magnesium and high scrap rate, achieve simple structure, improve product quality, and reduce manual operation intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

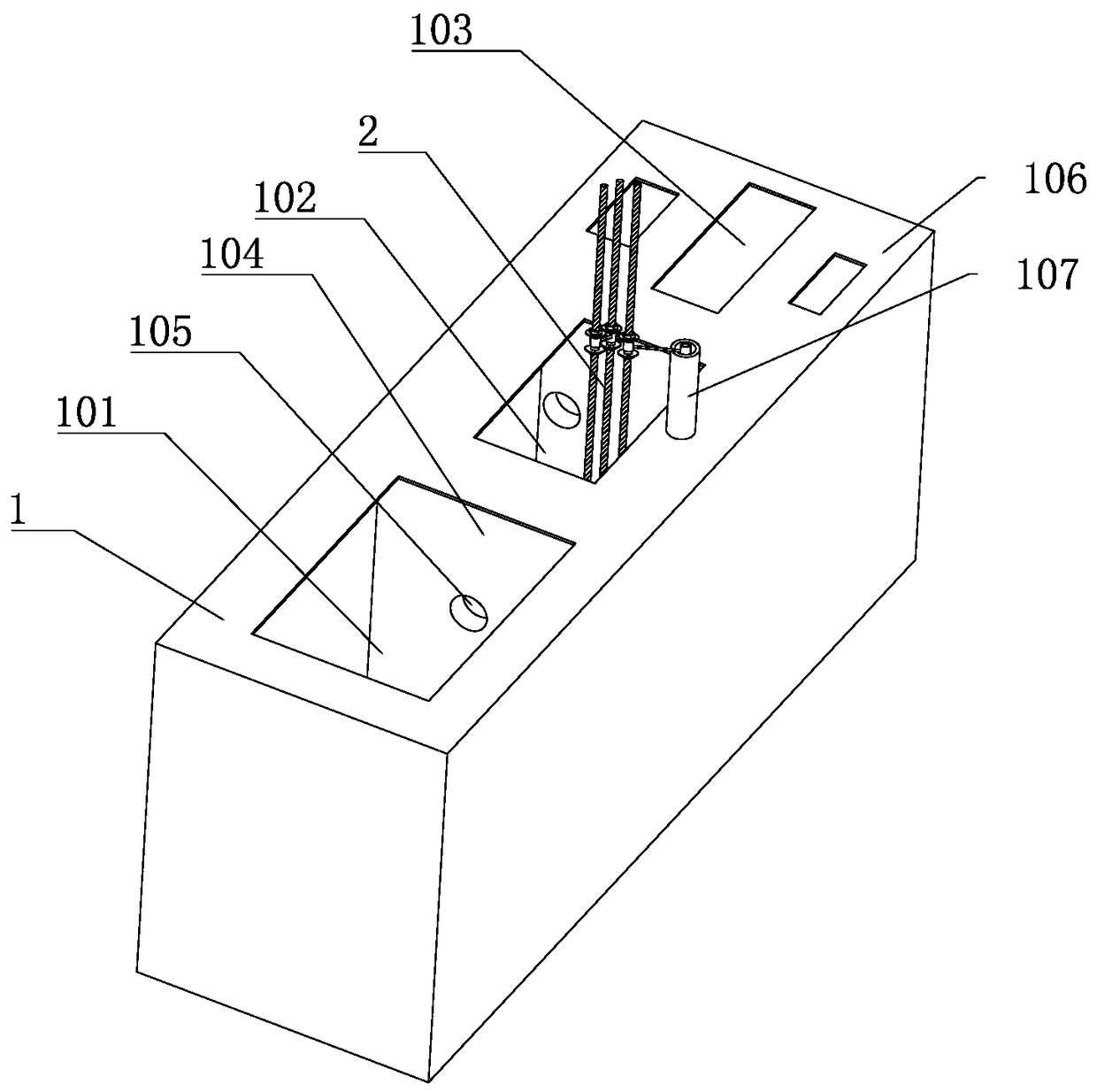

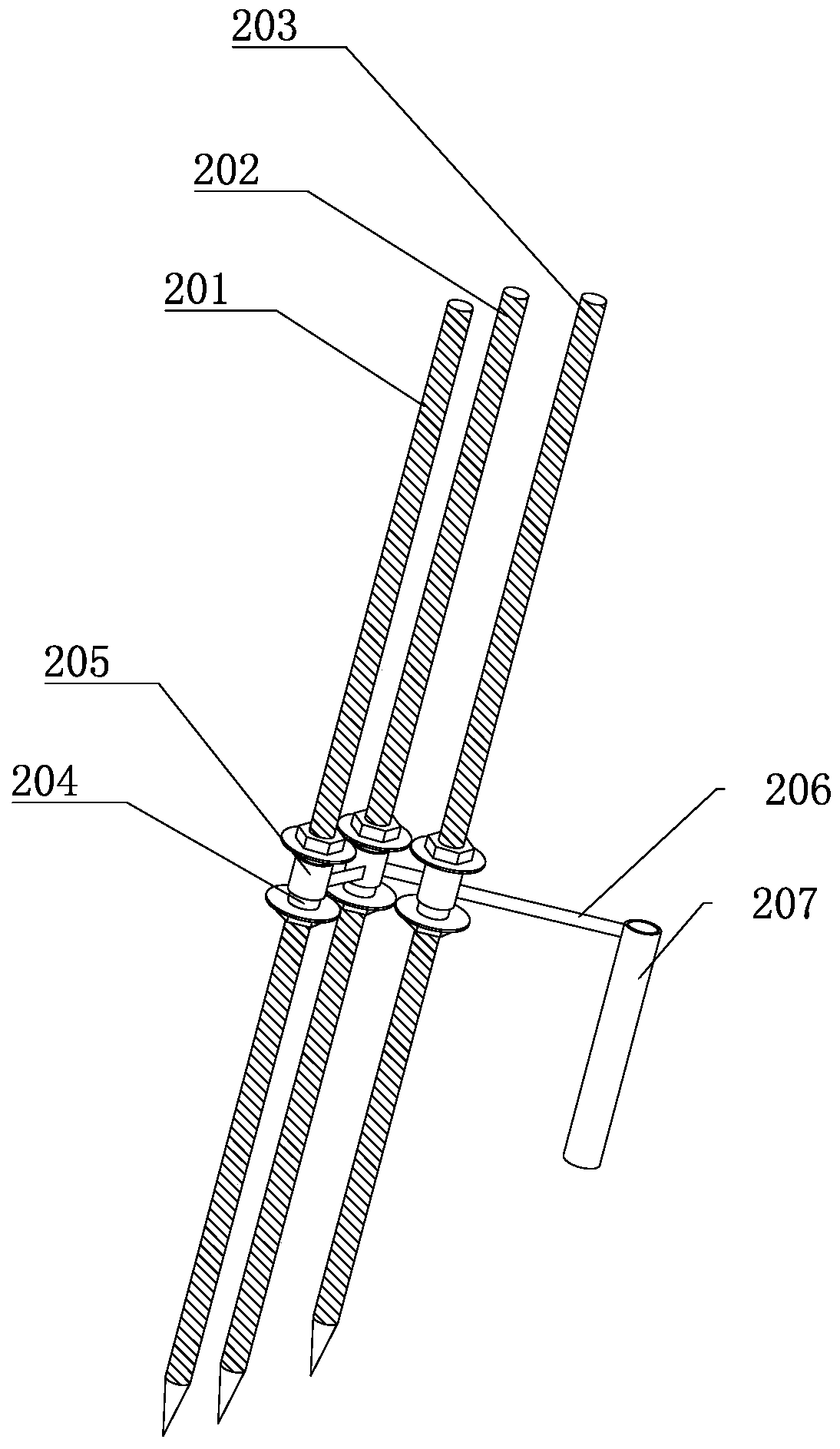

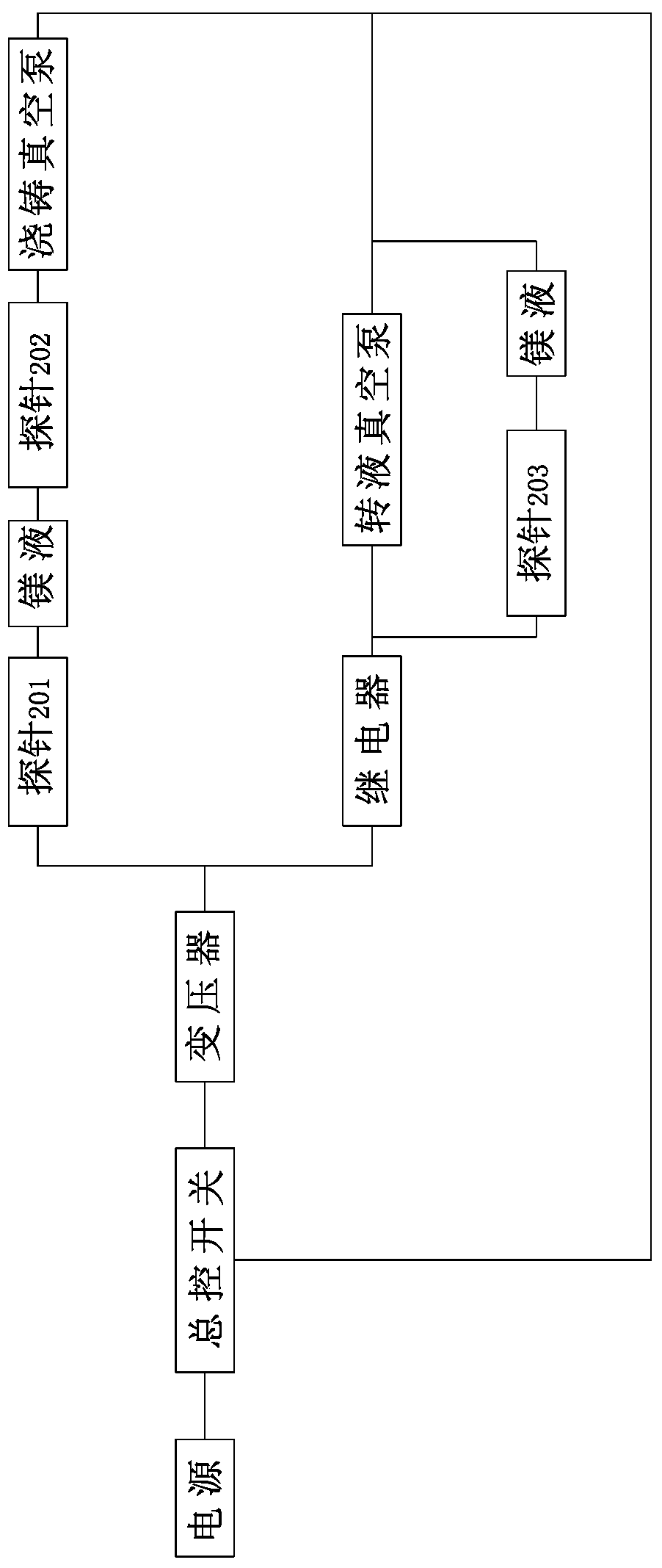

[0018] Such as figure 1 Shown is a preferred solution of the present invention, including a furnace chamber 1 and a liquid level balance controller 2. The furnace chamber 1 is divided into three chambers of a transfer chamber 101, a static chamber 102 and a casting chamber 103 in turn with two partitions 104. The circular connecting holes 105 that are all opened in the middle of the plate 104 have a diameter of 40-60 cm. According to the volume design of the furnace chamber, the connecting holes 5 on the two partitions are on the same horizontal plane, but the left and right positions are staggered, and Not connected. The furnace cavity 1 is also provided with a cover plate 106, and observation windows are opened on the cover plate 106 corresponding to the positions of the three cavities, and a fixing piec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com