Electromagnetic pulse based light alloy plate gas bulging forming device and forming method

An electromagnetic pulse and light alloy technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low forming precision and poor versatility of flat coils, and achieve high forming precision, fast forming speed and easy processing energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

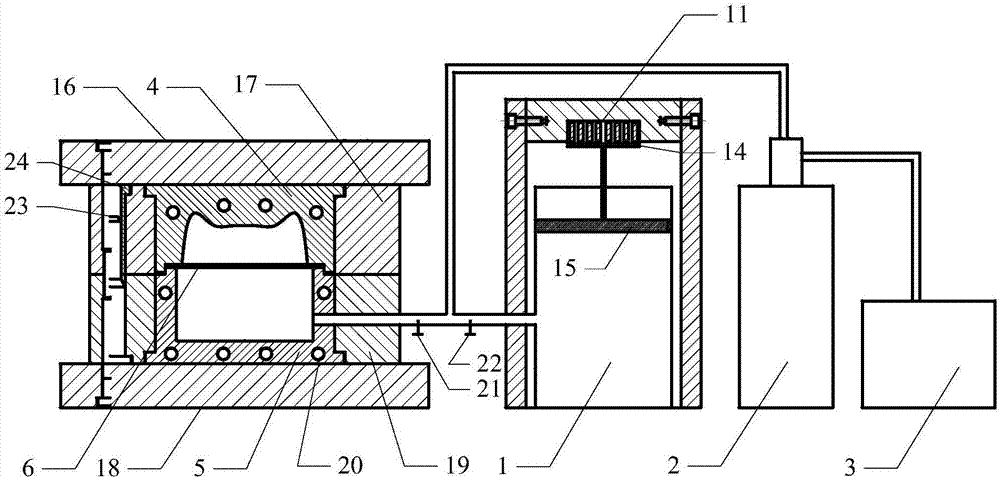

[0063] Embodiment one: combine below figure 1 This embodiment will be described in detail.

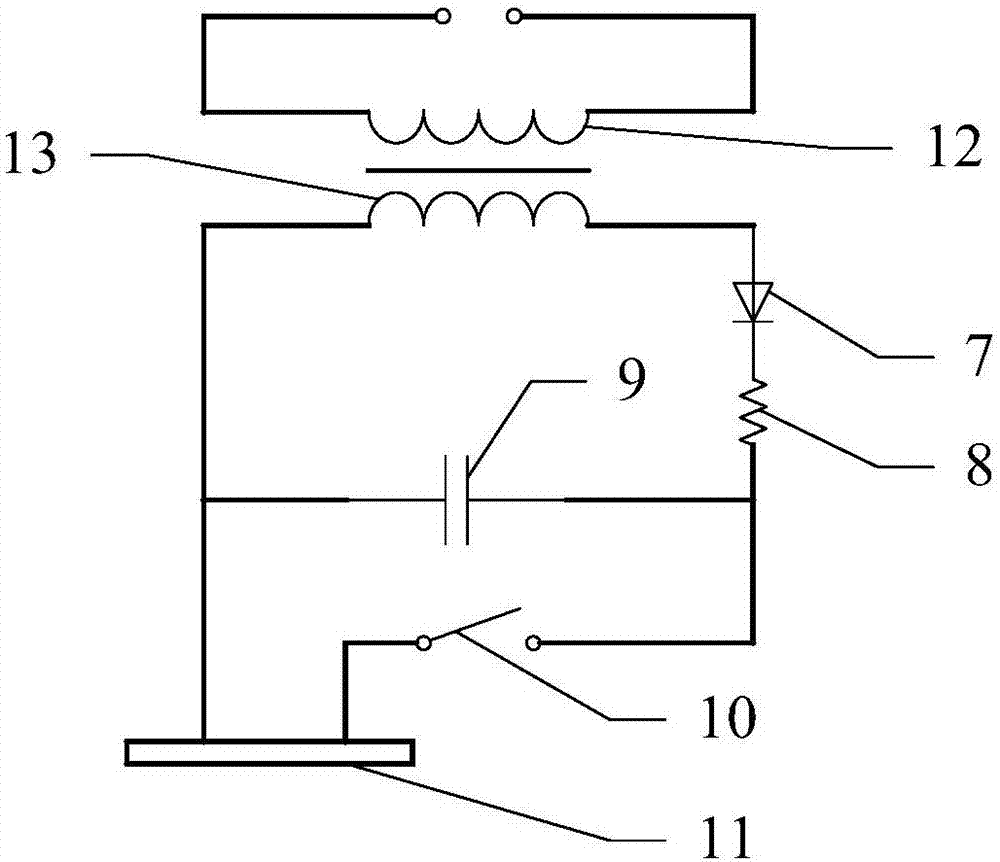

[0064] The electromagnetic pulse-based light alloy plate inflation forming device described in this embodiment includes a pressure unit, an inflation forming unit, a heating unit, a first high-pressure gas storage unit 1, a second high-pressure gas storage unit 2, and a gas pressurization unit 3 , electromagnetic pulse generating unit and compression unit;

[0065] The inflation forming unit includes a die 4 and a support body 5, the bottom surface of the die 4 is open, the top surface of the support body 5 is open, and the outer edge of the light alloy plate 6 to be formed is fixedly arranged on the opening end of the die 4 and the support body. Between the open ends of 5, the support body 5 and the light alloy plate 6 to be formed form an air chamber;

[0066] The pressure unit is used to apply pressure to the outer edge of the light alloy plate 6 to be formed, and the pressure is ...

Embodiment 2

[0072] Embodiment 2: This embodiment further limits the electromagnetic pulse-based light alloy plate inflation forming device described in Embodiment 1.

[0073] In the electromagnetic pulse-based light alloy plate inflation forming device described in this embodiment, the pressure unit is a hydraulic press.

Embodiment 3

[0074] Embodiment 3: This embodiment further limits the electromagnetic pulse-based light alloy plate inflation forming device described in Embodiment 2.

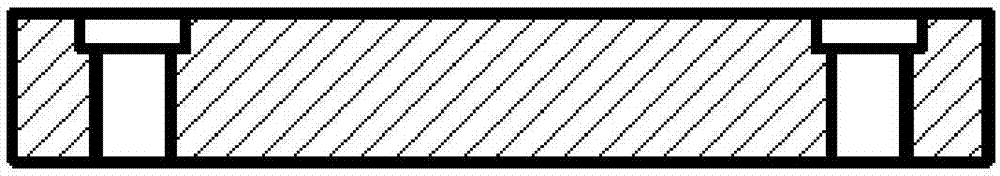

[0075] In the electromagnetic pulse-based light alloy plate inflation forming device described in this embodiment, the inflation forming unit further includes an upper die seat plate 16, an upper die cover plate 17, a lower die seat plate 18 and a lower die cover plate 19;

[0076] The upper die cover plate 17 is fixedly arranged on the bottom surface of the upper die seat plate 16, and the die 4 is fixedly arranged in the upper die cover plate 17;

[0077] The lower mold cover plate 19 is fixedly arranged on the top surface of the lower mold seat plate 18, and the support body 5 is fixedly arranged in the lower mold cover plate 19;

[0078] The die 4 is connected with the upper die set plate 17, the support body 5 and the lower die set plate 19, and the die 4 and the support body 5 are connected by tenon and tenon;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com