Dynamic water amount adjustment method for laminar flow cooling of medium-thickness plate and wide and thick plate considering head-tail temperature deviation

A technology of laminar cooling and temperature deviation, applied in the direction of temperature control, etc., can solve the problems of increasing quality accidents, different temperatures, uneven performance of head and tail, and achieve the effect of ensuring uniformity and avoiding quality accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

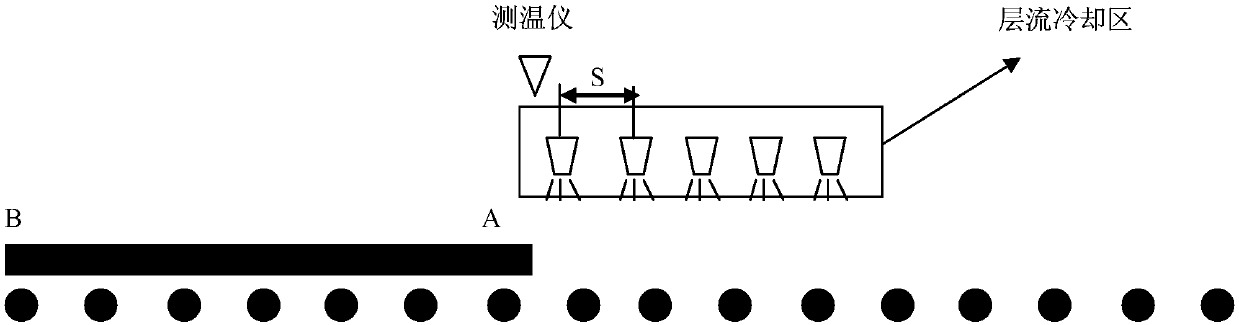

[0045] This embodiment is a dynamic adjustment method of water volume for laminar flow cooling of medium-thick plates and wide-thick plates in consideration of head-to-tail temperature deviation. A thermometer is provided at the end where the steel plate enters, and the method includes the following steps:

[0046] (1) Read the forward speed V of the steel plate and the total length L of the steel plate, the unit of V is m / s, and the unit of L is m;

[0047] (2) Calculating the water volume dynamic adjustment cycle C, C=1 / V, the unit of C is s, calculating the total number of times of adjustment Number, Number=L, wherein L takes an integer;

[0048] (iii) When the end A of the steel plate enters the laminar flow cooling zone, according to the initial temperature T detected by the thermometer and the target temperature Tt (the target temperature is the temperature that the steel plate is cooled to hope to achieve, such as the temperature before the cooling of the steel plate is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com