Strengthened floatation method of zinc oxide ore

A technology of zinc oxide ore and zinc oxide, which is applied in flotation, solid separation, etc., can solve problems such as difficulty in smooth production site process, deterioration of flotation environment and indicators, difficulty in defoaming flotation foam, etc., to achieve good flotation indicators, reducing the impact of slime, and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

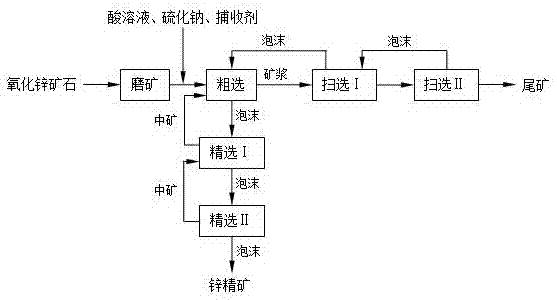

[0015] The ore to be selected is a refractory zinc oxide ore in Yunnan. The ore contains about 6% zinc and contains high mud. The ore is ground to -200 mesh, accounting for 90wt%, and the pulp concentration is controlled at 25wt%. Add 700g / t mass fraction as 20% hydrochloric acid solution was stirred for 5 minutes, then added 6kg / t of sodium sulfide for 3 minutes, and finally added 400g / t of composite collector, 2-amino-5-hexyloxy-sodium benzenethiolate and The mass ratio of dodecylamine is 5:1. After 5 minutes of action, roughing is carried out once, and the roughing foam is selected twice. The pulp in the roughing tank is swept twice. Level operation, the foam in the scavenging process returns to the upper level operation in sequence, the whole flotation process is as follows figure 1 As shown, the flotation zinc concentrate grade is 30%, and the recovery rate is 70%.

Embodiment 2

[0017] The ore to be selected is a lead-zinc oxide mine in Sichuan, with a zinc content of 8.5%. Zinc mainly exists in the form of smithsonite, followed by zinc sulfide (about 25%). Fine to -200 mesh accounts for 85wt%, the pulp concentration is controlled at 38wt%, add 200g / t of hydrochloric acid solution with a mass fraction of 36% and stir for 3 minutes, then add 3kg / t of sodium sulfide for 5 minutes to vulcanize, and finally add 200g of composite collector / t, the mass ratio of 2-amino-5-hexyloxy-sodium benzenethiolate and dodecylamine in the composite collector is 3:1, after 2 minutes of action, roughing is carried out once, and the foam of roughing is refined twice. The ore pulp in the roughing tank is swept twice. During the beneficiation process, the ore returns to the upper level of operation in sequence, and the foam during the sweeping process returns to the upper level of operation in sequence. The entire flotation process is as follows: figure 1 As shown, the flot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com