Large-torque medical trolley caster sleeving structure

A high-torque, caster technology, applied in the field of medical equipment, can solve the problems of inability to achieve quick fit, poor bearing strength of casters, and difficult to guarantee quality, achieve light disassembly, simplify assembly difficulty, and improve compressive and bending strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

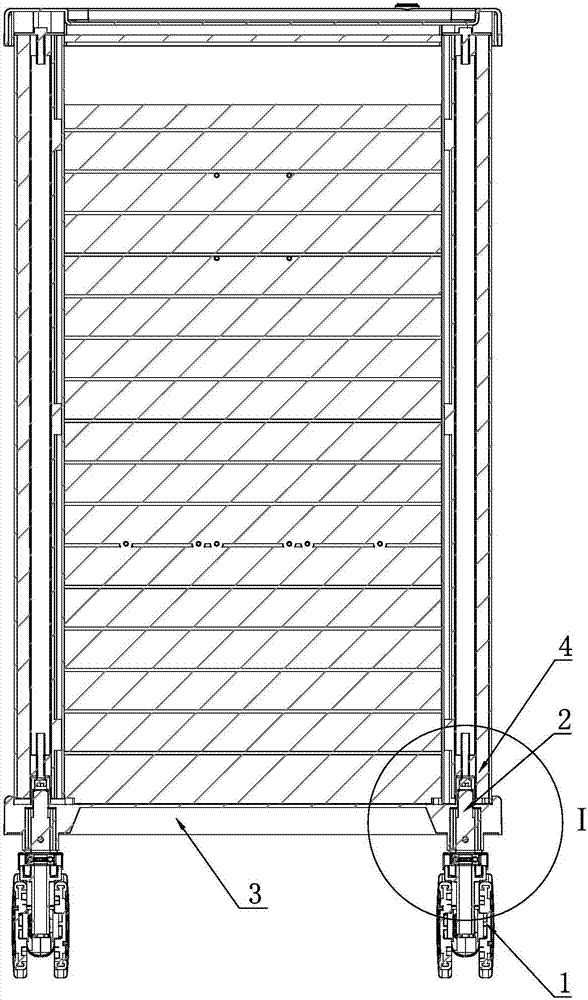

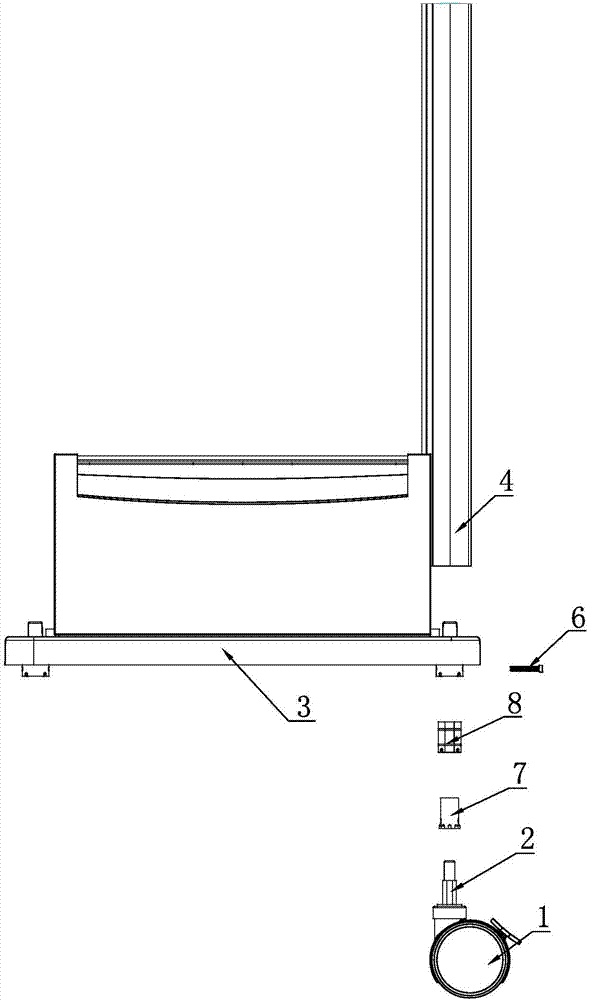

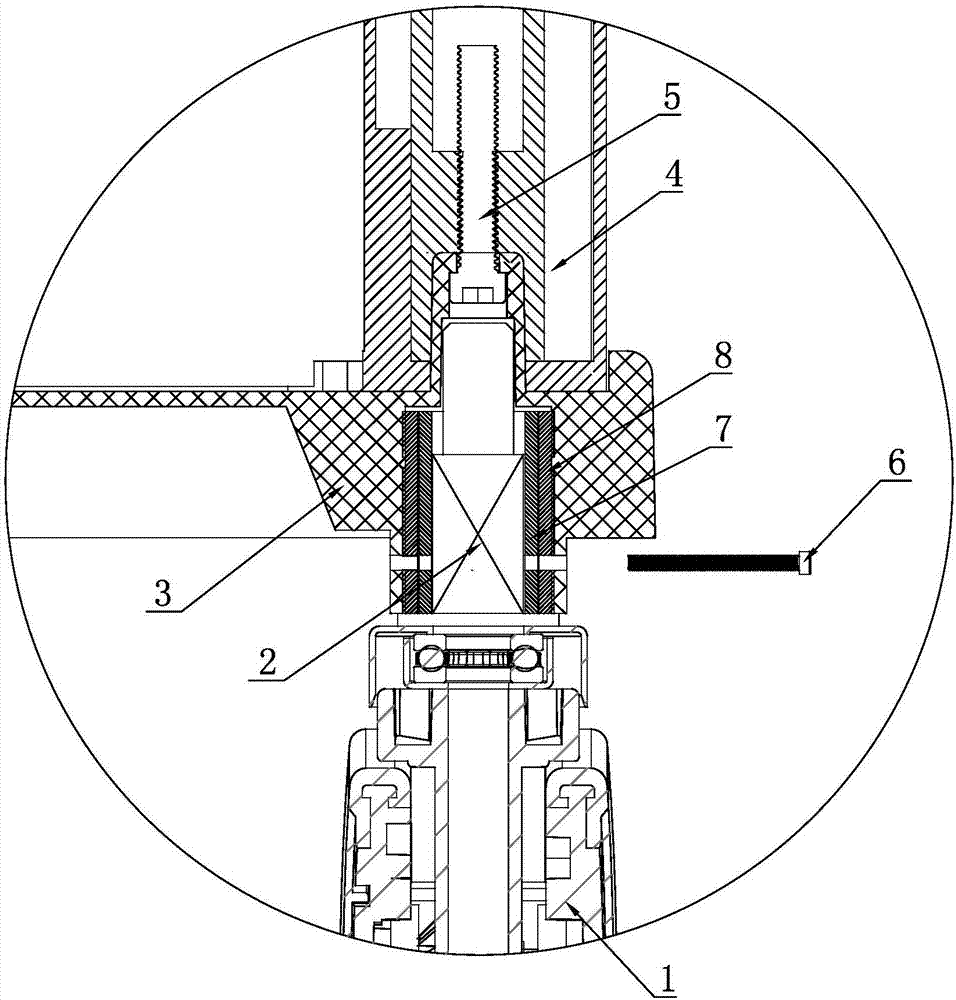

[0035] Embodiment 1: A high-torque medical cart caster set structure, such as Figure 1 to Figure 11 As shown, it includes a caster 1, a caster connecting shaft 2, a frame bottom plate 3, a frame pull tube 4, a fixing screw 5, an axial pin 6, a circumferential limit sleeve 7 and a frame column 9, and the caster is connected The shaft 2 includes a circumferential limiting shaft section 21 and a torque enhancing shaft section 22, and the cross-sectional shape of the circumferential limiting shaft section 21 is as follows: Figure 5 As shown, that is, the figure column is cut into a plane, and a pin hole 23 is provided on the plane. The torque enhancing shaft section 22 is arranged above the circumferential limiting shaft section 21, and the caster connecting shaft 2 passes through the circumferential limiting shaft section 21. Fixedly connected to the top of the caster 1; on the upper end surface of the four corners of the frame base plate 3 is provided with an upper positioning...

Embodiment 2

[0036] Embodiment 2: The difference from Embodiment 1 is that a conversion shock-absorbing sleeve 8 is embedded in the inner hole of the lower positioning sleeve 32 of the frame bottom plate 3, and the circumferential limit sleeve 7 is set on the conversion shock-absorbing sleeve 8. In the inner hole, the axial engagement between the lower end surface of the circumferential limiting sleeve 7 and the lower end shoulder of the conversion damping sleeve 8 is realized through a rectangular concave-convex joint block.

[0037] In the above two embodiments, the cross-sectional shape of the circumferential limiting shaft section 21 can be changed, and Figure 6 to Figure 9 Either of those will do.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com