Bacillus coagulans mixed strain fermentation bean food and preparation method thereof

A technology of Bacillus coagulans and fermented food, which is applied in the direction of food ingredients, the function of food ingredients, and food ingredients as taste improvers, etc. It can solve the problems of resistance to the promotion of natto, improve the intestinal micro-ecological environment, and promote gastrointestinal digestion , the effect of preventing cancer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 A kind of Bacillus coagulans mixed Bacillus natto liquid fermented bean beverage

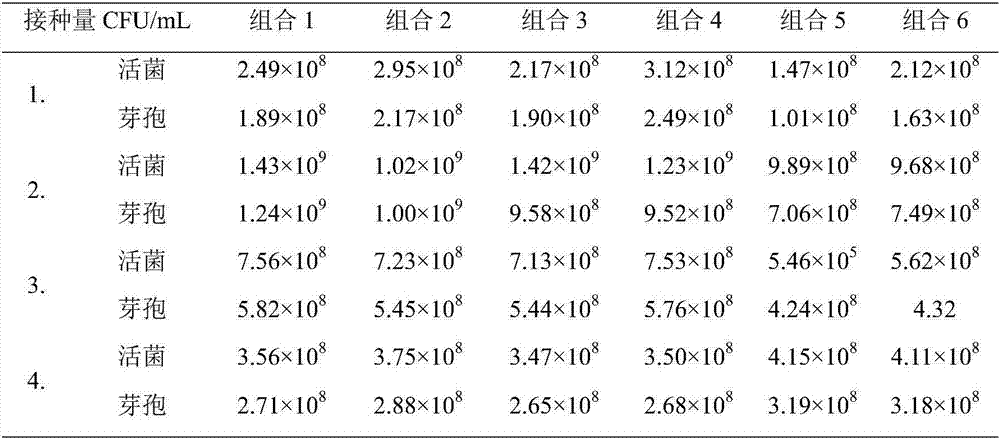

[0047] (1) Determination of optimal inoculum volume

[0048] The selected bacillus natto, that is, Bacillus subtilis is Bacillus subtilis TK-1, and the preservation number is CGMCC No.4731.

[0049] The selected Bacillus coagulans is Bacillus coagulans (Bacillus coagulans) TQ33, and the preservation number is CGMCC No.5233.

[0050] 6 groups of selected bean combinations:

[0051] Combination 1: 100% soybeans; Combination 2: 100% black beans; Combination 3: 50% soybeans + 50% black beans; Combination 4: 40% soybeans + 60% mixed beans, wherein the mixed beans are mung beans, red beans, white kidney beans, Mixed equal parts of pinto beans, chickpeas and lentils; Combination 5: 40% black beans + 60% mixed beans, where the mixed beans are an equal mix of mung beans, red beans, white kidney beans, pinto beans, chickpeas and lentils ; Combination 6: 20% soybeans + 20% black bean...

Embodiment 2

[0109] Embodiment 2 A kind of Bacillus coagulans mixed Bacillus natto liquid fermented bean food

[0110] Bacillus subtilis subsp. subtilis was selected as Bacillus subtilis, and the CGMCC strain number was 1.2163.

[0111] The selected Bacillus coagulans is Bacillus coagulans, and the CGMCC strain number is 1.2407.

[0112] The activation medium is as follows: After mixing and washing soybeans and black beans, add 5g of soybeans to every 100mL of water to make a slurry and homogenize.

[0113] The fermentation medium is: 30% of soybeans, 30% of black beans, and 40% of other beans. After the beans are washed, 5g of beans are added to each 100mL of water for beating and homogenization. The homogenization temperature is 65°C and the pressure is 20.0MPa. Other beans are red beans, mung beans, white kidney beans, flower kidney beans, chickpeas and lentils mixed in equal amounts, and sterilized at 121°C for 20 minutes.

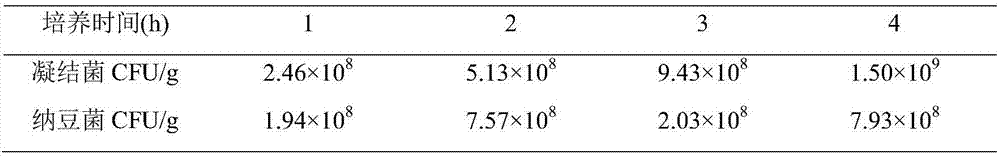

[0114] Bacillus coagulans and Bacillus natto started from g...

Embodiment 3

[0123] Embodiment 3 Bacillus coagulans mixed Bacillus natto solid-state fermentation bean food technology

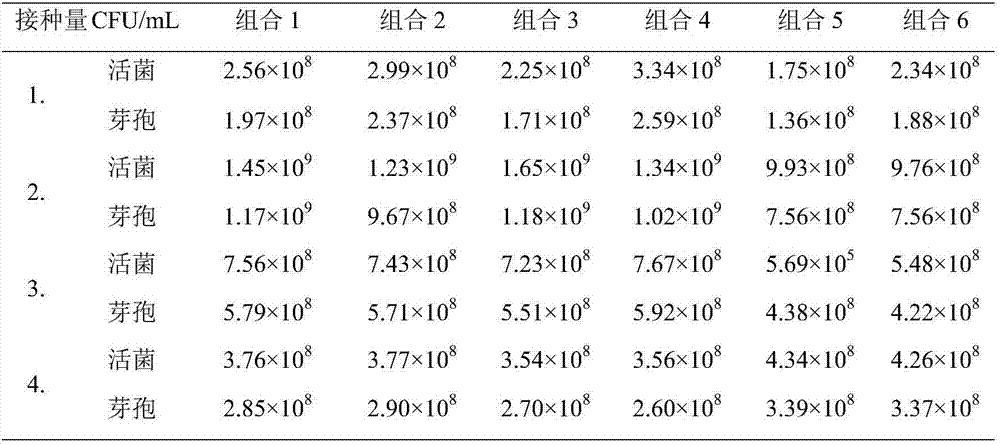

[0124] (1) Optimal inoculum volume

[0125] The selected bacillus natto, that is, Bacillus subtilis is Bacillus subtilis TK-1, and the preservation number is CGMCC No.4731.

[0126] The selected Bacillus coagulans is Bacillus coagulans (Bacillus coagulans) TQ33, and the preservation number is CGMCC No.5233.

[0127] 6 combinations of selected beans: combination 1: 100% soybeans; combination 2: 100% black beans; combination 3: 50% soybeans + 50% black beans; combination 4: 40% soybeans + 60% mixed beans, of which mixed beans Combination 5: 40% black beans + 60% mixed beans, where mixed beans include mung beans, red beans, white kidney beans, flower kidney beans, chickpeas Mix equal parts of chickpeas and lentils; combination 6: 20% soybeans + 20% black beans + 60% mixed beans, where mixed beans include red beans, mung beans, white kidney beans, pinto beans, chickpeas an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com