A light-duty and repeatedly retractable bundled optical cable and its preparation method

An optical cable, light technology, applied in the field of bundled optical cables, can solve the problems of optical fiber damage, heavy weight, optical fiber fracture, etc., and achieve the effects of rodent damage resistance, low linear expansion coefficient, and low optical fiber pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The specific realization process of this embodiment is as follows:

[0044] 1. Optical fiber coloring

[0045] A layer of coloring material is coated on the single-mode optical fiber. In this embodiment, the ink is preferred. The optical fiber ink has the advantages of good fluidity, fast curing speed, and not easy to fade. Optical fiber ink should be stirred before processing to ensure uniform color of the ink. The stirring speed is 8 rpm and the time is 4 hours.

[0046] This process adopts UV ultraviolet curing process. The outer diameter of the colored optical fiber is 0.24mm, and it is rewound on a special optical fiber disk. The tension of the pay-off line is 50g, and the tension of the take-up line is 60g. Jitter, on the other hand, can ensure the quality of the optical fiber on the take-up reel, the speed is 1200m / min, the size of the coloring mold is 258μm, and the temperature of the coloring mold is controlled at 35°C.

[0047] 2. Production of optical fiber...

Embodiment 2

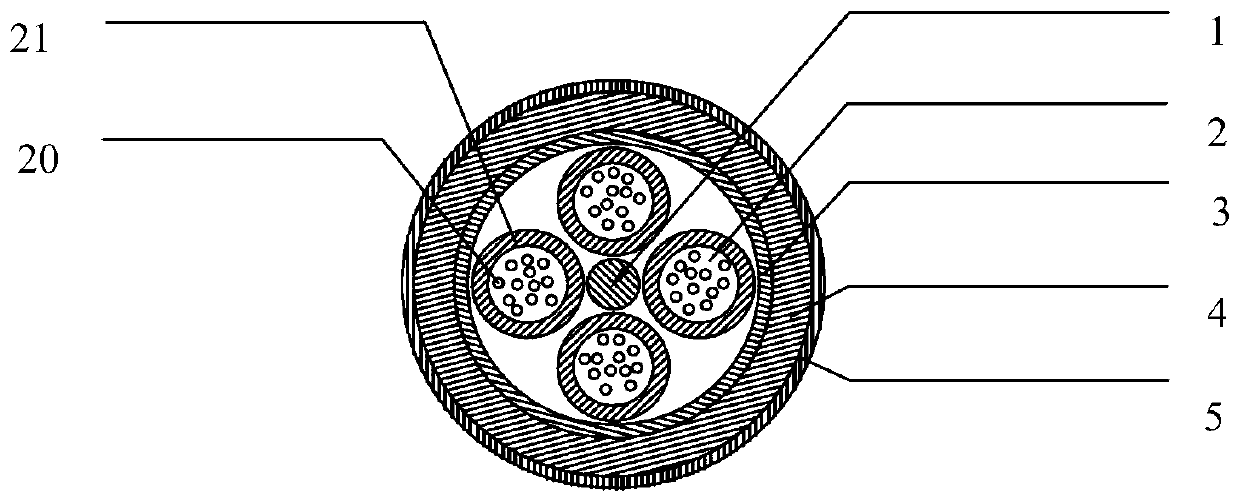

[0056] The outer diameter of the optical fiber unit 2 is 3.0 mm, and the optical fiber unit 2 is formed by extruding a layer of polyolefin after laying glass yarns on the outer periphery of 12 colored optical fibers.

[0057] Colored fiber is OM3 multimode fiber. The cable sheath 4 is polyolefin with a wall thickness of 1 mm and a diameter of 10 mm. The reinforcing member 3 is made of polyparabenzobenzobisoxazole.

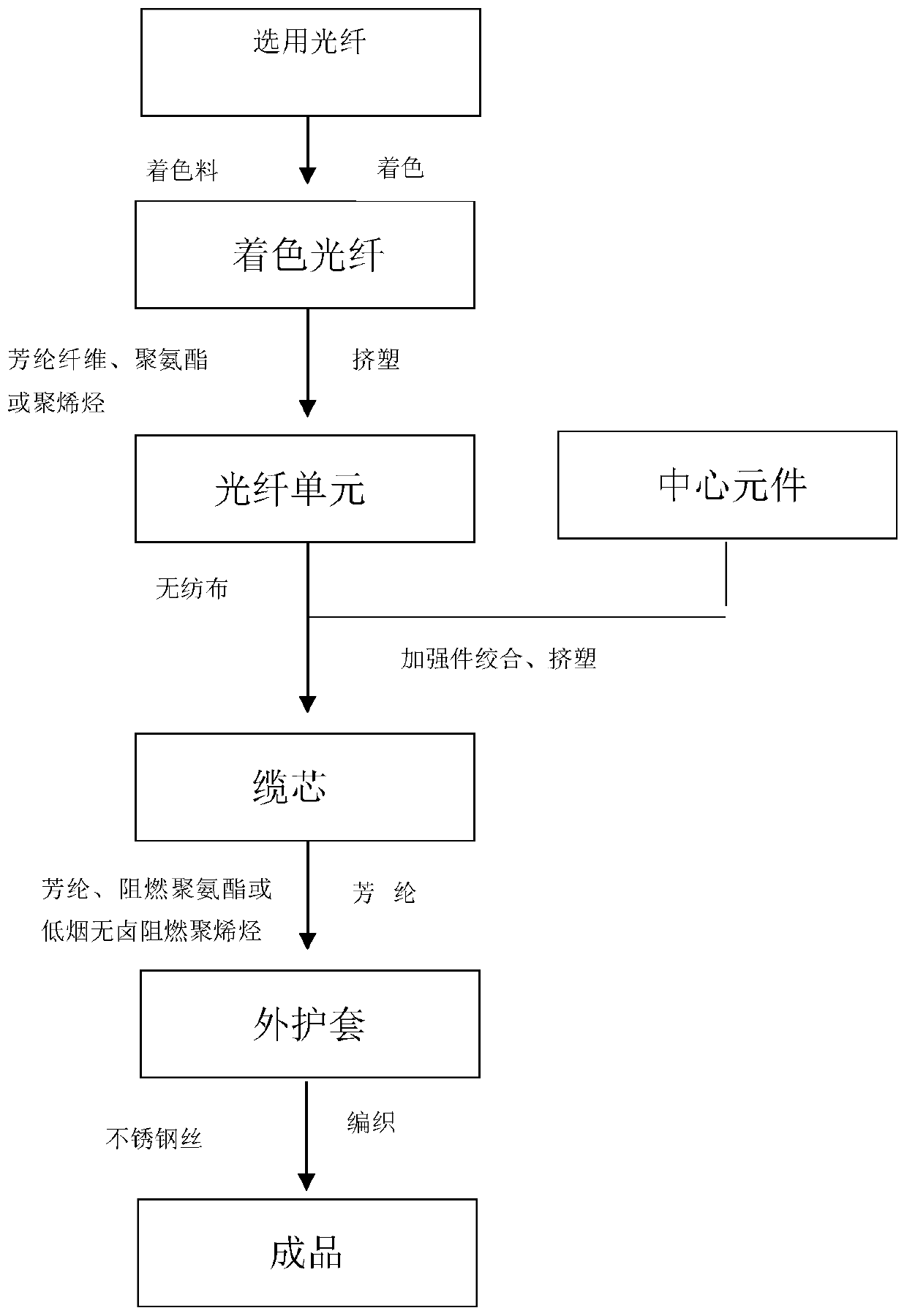

[0058] For the specific implementation process of this embodiment, see image 3 as follows:

[0059] 1. Optical fiber coloring

[0060] Apply a layer of ink to the outside of bend-insensitive multimode OM3 optical fiber. Optical fiber ink should be stirred before processing to ensure uniform color of the ink. The stirring speed is 8 rpm and the time is 5 hours.

[0061] This process adopts UV ultraviolet curing process. The outer diameter of the colored optical fiber is 0.26mm, and it is rewound on a special optical fiber reel. The tension of the wire is 60g, ...

Embodiment 3

[0071] The specific realization process of this embodiment is as follows:

[0072] 1. Optical fiber coloring

[0073] Coat a layer of ink on the bend-insensitive OM4 optical fiber. The optical fiber ink has the advantages of good fluidity, fast curing speed, and not easy to fade.

[0074] The optical fiber ink should be stirred before processing to ensure uniform color of the ink. The stirring speed is 8 rpm and the time is 4 hours.

[0075] This process adopts UV ultraviolet curing process. The outer diameter of the colored optical fiber is 0.25mm, and it is rewound on a special optical fiber reel. The tension of the wire is 55g, the tension of the wire is 65g, the speed is 1200m / min, and the size of the coloring mold is 258μm. The temperature of the coloring mold is controlled at 25°C.

[0076] 2. Production of optical fiber unit

[0077] Evenly twist aramid fibers around the 6 above-mentioned colored optical fibers and extrude the sheath at the same time, twist 5 pieces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com