Mud ditch capable of cleaning rock debris conveniently

A mud tank, a convenient technology, applied in the direction of earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problems of inconvenient cleaning, debris accumulation and blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

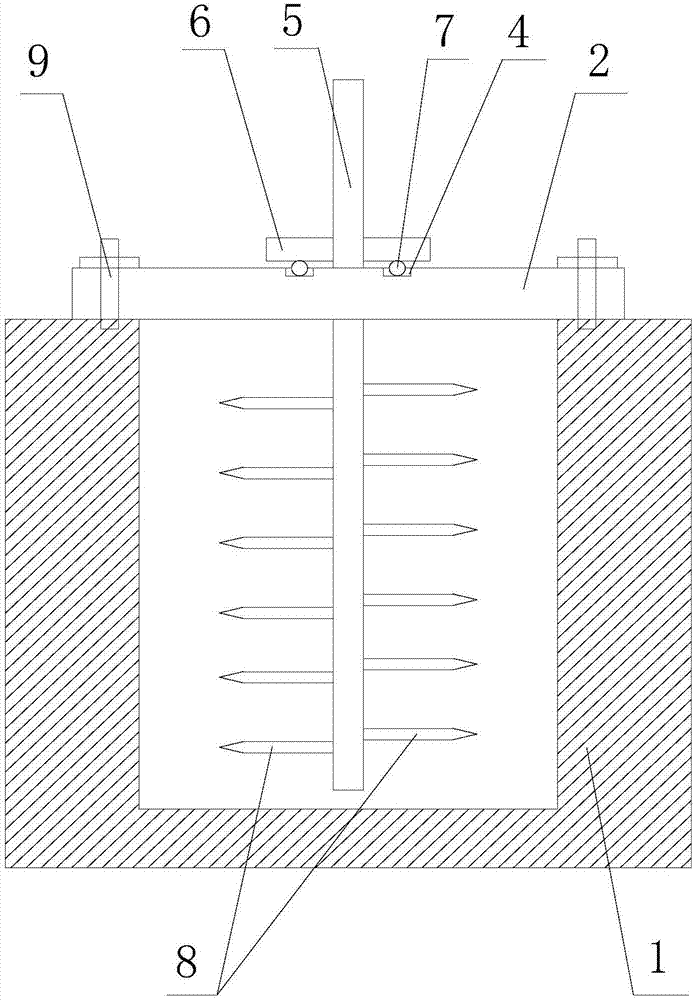

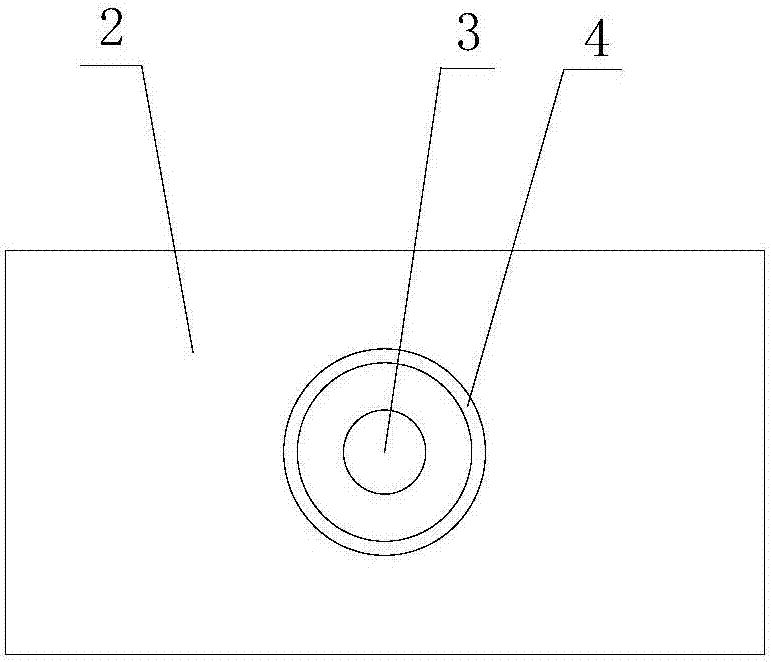

[0022] Such as figure 1 and figure 2 The mud tank shown to facilitate the processing of accumulated rock debris includes a tank body 1, a plate 2 spanning the tank body 1 is erected at the upper end of the tank body 1, and a circular through hole 3 and an annular groove are opened in the center of the plate 2 4. The groove 4 is concentric with the through hole 3, and the through hole 3 is located inside the ring of the groove 4; it also includes a stirring rod 5 passing through the through hole 3, and the lower end of the stirring rod 5 is connected to the bottom of the tank body 1 The distance between them is 5cm; the stirring rod 5 is covered with a disc-shaped rotating disk 6, and the rotating disk 6 is fixedly connected with the stirring rod 5; the upper and lower surfaces of the rotating disk 6 are all perpendicular to the axis of the stirring rod 5, and the rotating disk The lower surface of 6 is provided with N rollers 7, and the N rollers 7 are evenly distributed in ...

Embodiment 2

[0025] Such as figure 1 and figure 2 The shown mud tank is convenient for processing accumulated cuttings. On the basis of Example 1, in view of the well wall falling off with a diameter of 5-8 cm in the returned drilling fluid, the lower end of the stirring rod 5 and the bottom of the tank body 1 are set. The distance between them is 10cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com