A kind of method for preparing darunavir intermediate

A technology of compounds and catalysts, applied in the field of medicine, can solve the problems of high cost of raw materials and poor atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

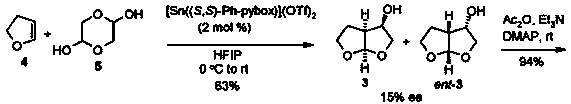

Method used

Image

Examples

Embodiment 1

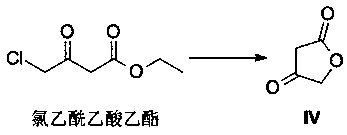

[0037] Synthesis of Example 1 Compound IV

[0038]

[0039] Add 45g (3eq) of potassium acetate and 120mL of acetic acid into a three-necked flask, and then add 25g (0.3mol, 1eq) of ethyl chloroacetoacetate; heat the above mixture to 80-90°C for 12h. After the reaction, cool to room temperature, filter, and collect the filtrate. Add 200mL of 10% hydrochloric acid solution to the filtrate and react at 15-20°C for 48 hours. Most of the acetic acid was distilled off under reduced pressure, and the remaining solution was extracted three times with 600 mL of ethyl acetate, the extracts were combined, and the solvent was distilled off to obtain compound IV, weight 13.5 g, yield 45%.

Embodiment 2

[0040] Synthesis of Example 2 Compound III

[0041]

[0042] Add 25g (0.25mol, 1eq) of compound IV, 69g (2.0eq) of potassium carbonate, 2.6g (0.05eq) of potassium iodide into the reaction flask, and add 200mL of N,N-dimethylformamide. Heat the mixture to 40-50°C for 30 minutes, then add 30g (1.5eq) of chloroethanol dropwise. After the addition, keep warm at 40-50°C for 24 hours. Filtrate, collect the filtrate, distill under reduced pressure, add 100mL water and 100mL ethyl acetate to the distillation residue, stir for 30min, separate after standing, extract the aqueous phase with 2×100mL ethyl acetate, combine the organic layers, and the organic phases are sequentially Wash with 60mL saturated brine and 60mL distilled water, let stand and separate the layers, dry the organic phase with anhydrous magnesium sulfate for 2 hours, filter, and concentrate the filtrate to obtain compound III, weight 27g, yield 75%.

Embodiment 3

[0043] Synthesis of Example 3 Compound III

[0044] Add 20g (0.20mol, 1eq) of compound IV, 10.8g (1.1eq) of sodium methoxide, 1.5g (0.05eq) of potassium iodide into the reaction flask, and add 100mL of tetrahydrofuran. The mixture was heated to 20-30°C for 30 minutes, then 25g (1.5eq) of chloroethanol was added dropwise, and the temperature was raised to 40-50°C for 24 hours. Use 2N dilute hydrochloric acid to adjust the pH of the reaction solution to 4-5, separate the organic layer, extract the aqueous layer with 200mL ethyl acetate, combine the organic phases and dry over anhydrous magnesium sulfate for 2 hours, filter, and concentrate the filtrate to obtain compound III, weight 30g , The yield is 83.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com