Laminating equipment for pvc laminated floor

A film covering and equipment technology, applied in the field of PVC floor production equipment, can solve the problems of color pattern film pattern deformation and distortion, insufficient horizontal size, and unqualified products, so as to avoid insufficient coverage defects, increase yield, and reduce film deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiment of the film-covering equipment for the PVC film-covered floor of the present invention will be further described below in conjunction with the accompanying drawings.

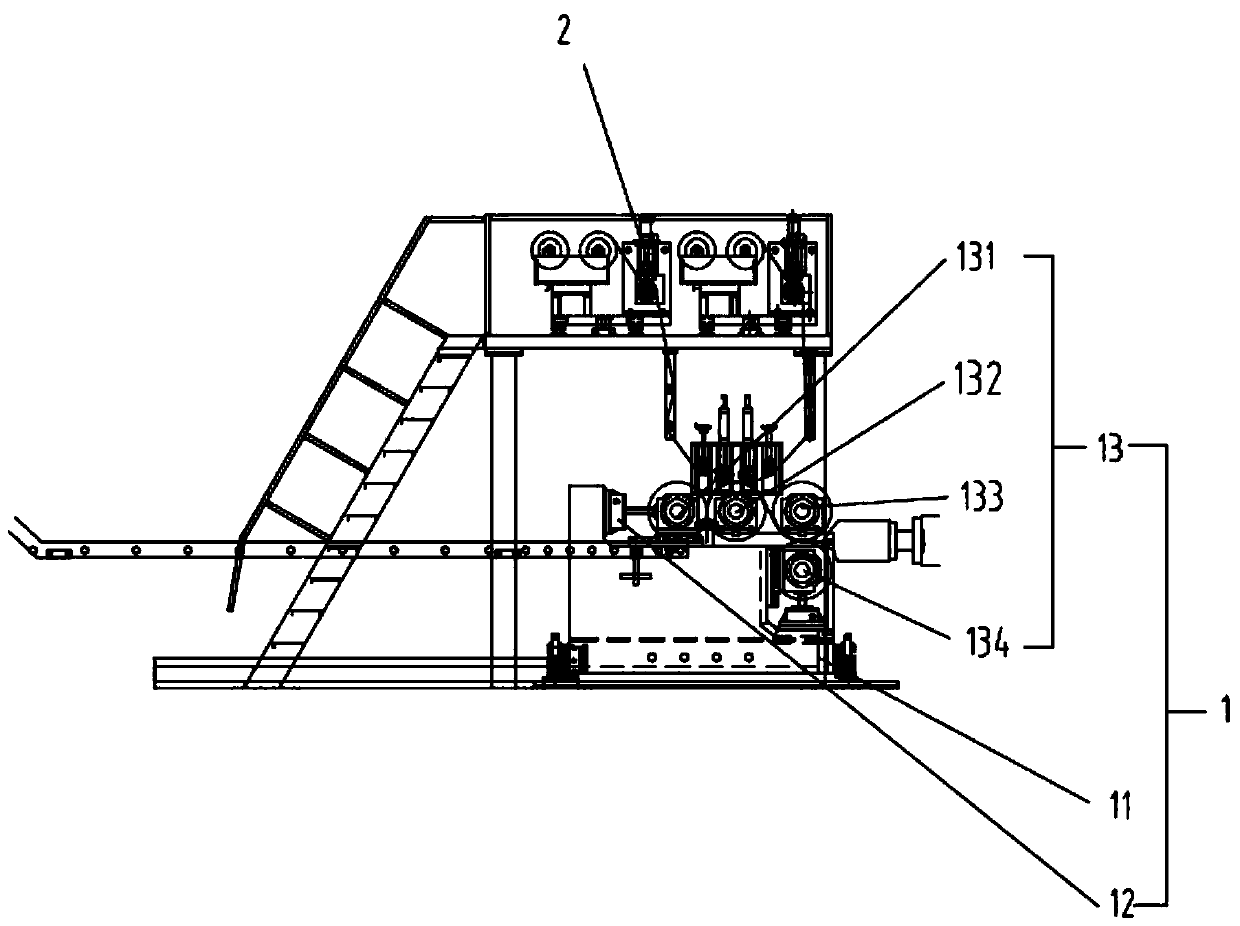

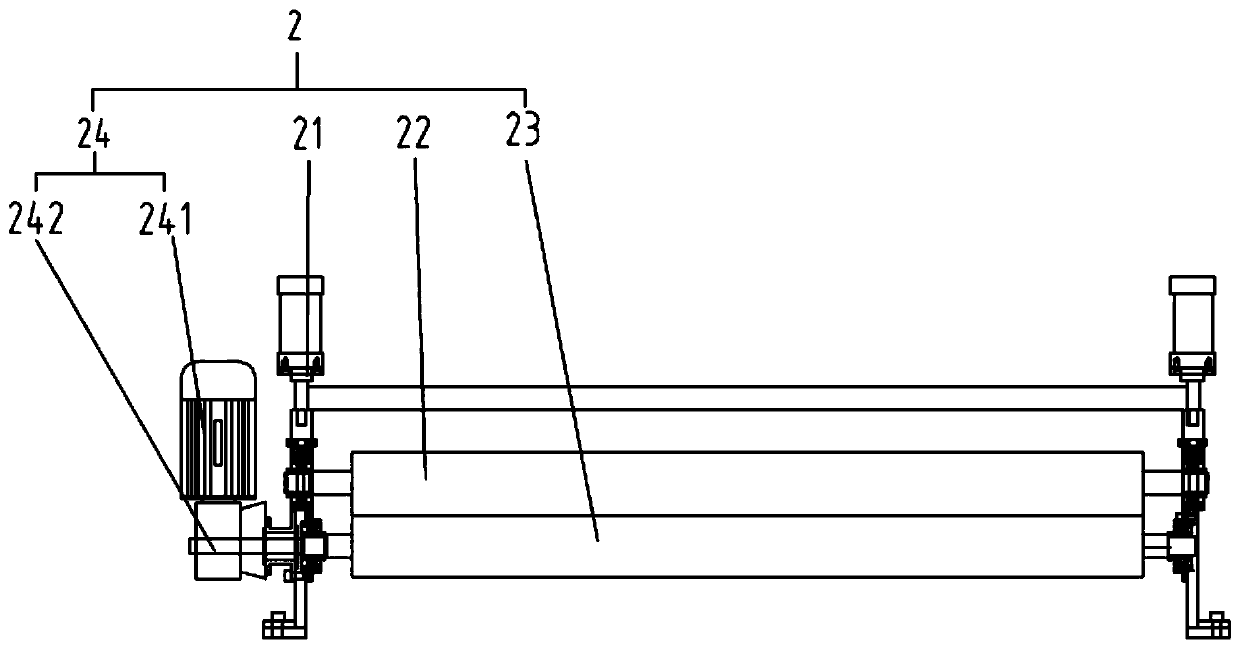

[0016] A film covering equipment for PVC film-coated flooring, comprising a calendering mechanism 1 and a traction mechanism, the calendering mechanism 1 comprising a frame 11, a roller opening and closing mechanism 12, and a horizontal four-roll calender assembly 13, the horizontal four-roll calender The optical machine assembly 13 includes a first smooth roll 131, a second smooth roll 132, a network roll 133 and a pattern roll 134 in sequence, and the traction mechanism includes a left wallboard, a right wallboard, and a traction system 2, and the traction system 2 includes a cylinder pressing device 21 , the upper steel roller 22 , the lower rubber roller 23 and the lower rubber roller driving device 24 , and the outlet of the traction mechanism faces the network roller 133 . The lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com