Rod punching and shearing die

A punching and shearing and rod material technology, which is applied in the field of mechanical punching and shearing, can solve the problems of elbows at the cut, time-consuming, and reduce the production efficiency of the production line, and achieve the effect of flat section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

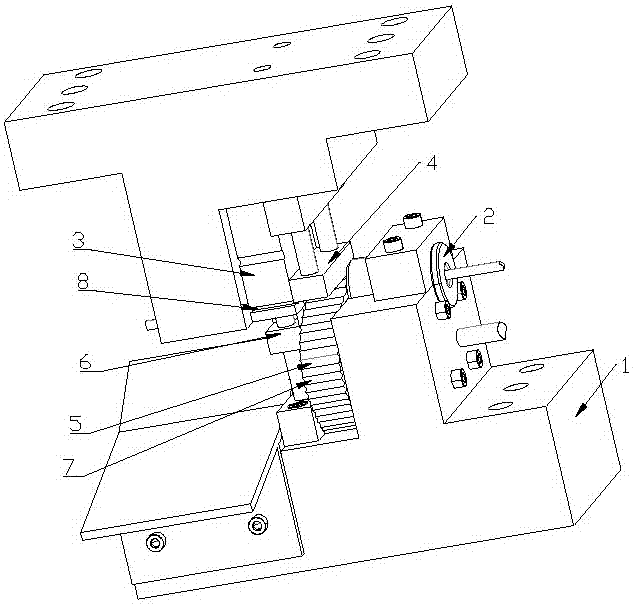

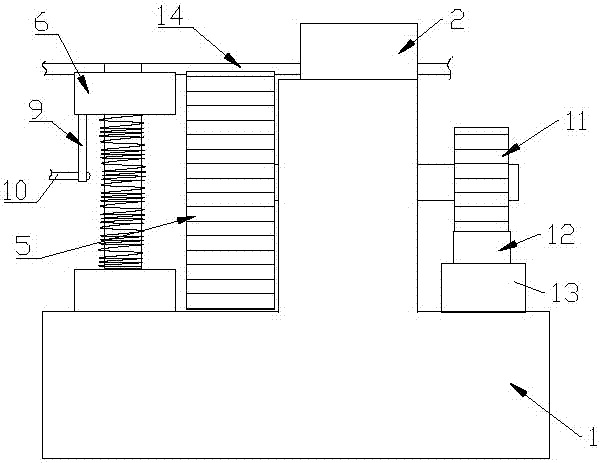

[0015] The reference signs in the drawings of the description include: base 1, material guide sleeve 2, upper punching block 3, upper pressing block 4, lower punching block 5, lower pressing block 6, punching groove 7, punching Groove 8, support bar 9, limit pin 10, driven gear 11, rack 12, cylinder 13, bar material 14.

[0016] The embodiment is basically as attached figure 1 Shown: rod material punching and shearing die, including base 1, material guide mechanism, material breaking mechanism and limit mechanism, material guide mechanism includes material guide sleeve 2 installed on base 1, and material guide sleeve 2 is equipped with There is a material guide hole for the rod material 14 to pass through, and the right end entrance of the material guide hole is in a flared shape gradually increasing to the right, and the material guide sleeve 2 guides the rod material 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com