Tab strengthened indentation mechanism

A tab and indentation technology, which is applied in the field of lithium battery automation equipment, can solve problems such as damage and lower product yield, and achieve the effects of convenient gap adjustment, easy popularization, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

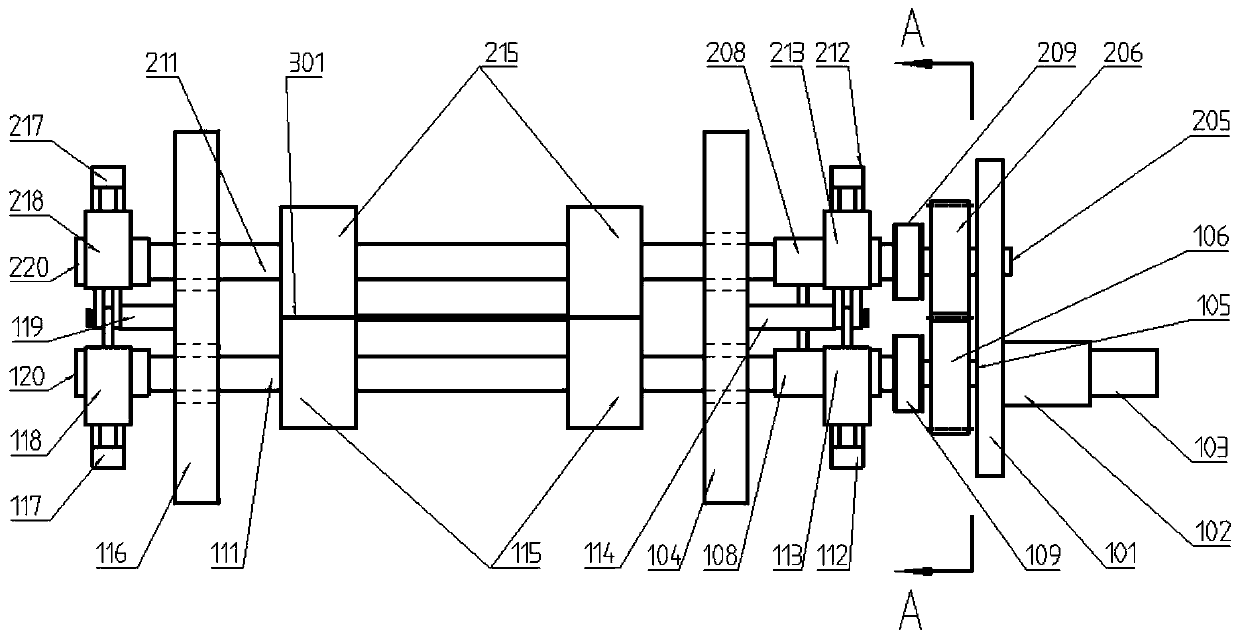

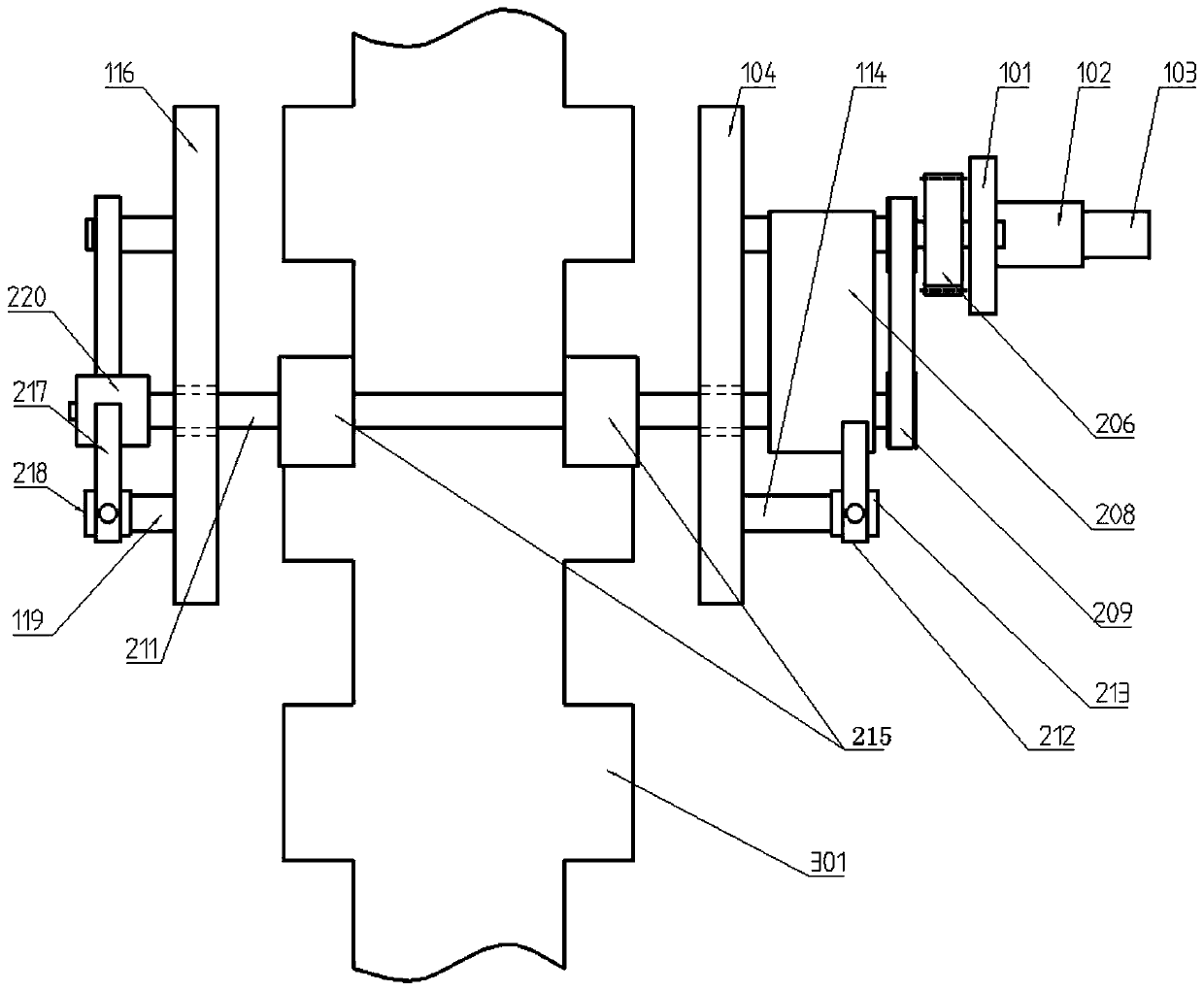

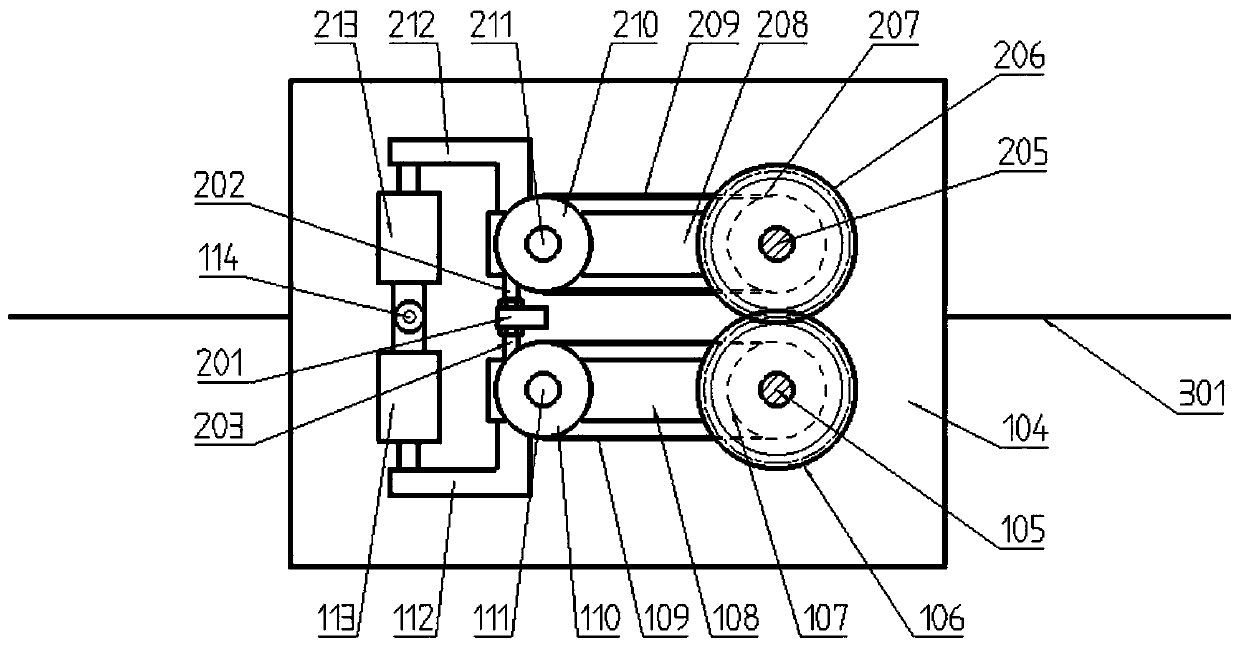

[0026] The present invention will be further described below in conjunction with specific drawings.

[0027] In the description of the following specific embodiments, the coordinates are all adopted: figure 1 The direction perpendicular to the paper surface is the front, and vice versa.

[0028] Such as figure 1 , figure 2 As shown, the lug reinforcement indentation mechanism of the present invention includes a first frame plate 101, a reducer 102 is installed on the right side of the first frame plate 101, the input shaft of the reducer 102 is connected to a motor 103, and the first frame The left side of the frame plate 101 wears a first shaft 105 and a third shaft 205. The first shaft 105 is connected to the output shaft of the reducer 102. The first shaft 105 is equipped with a first gear 106 and a first timing pulley 107. The shaft 105 passes through the first bearing seat 108 and is mounted on the second frame plate 104. A second gear 206 and a third synchronous pulley 207 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com