High-efficiency boiler dedusting desulfurization denitrification device

A technology for desulfurization, denitrification, and dust removal devices, which is applied in gas treatment, membrane technology, and dispersed particle separation. The effect of low range requirements, reduction of circulating water volume, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

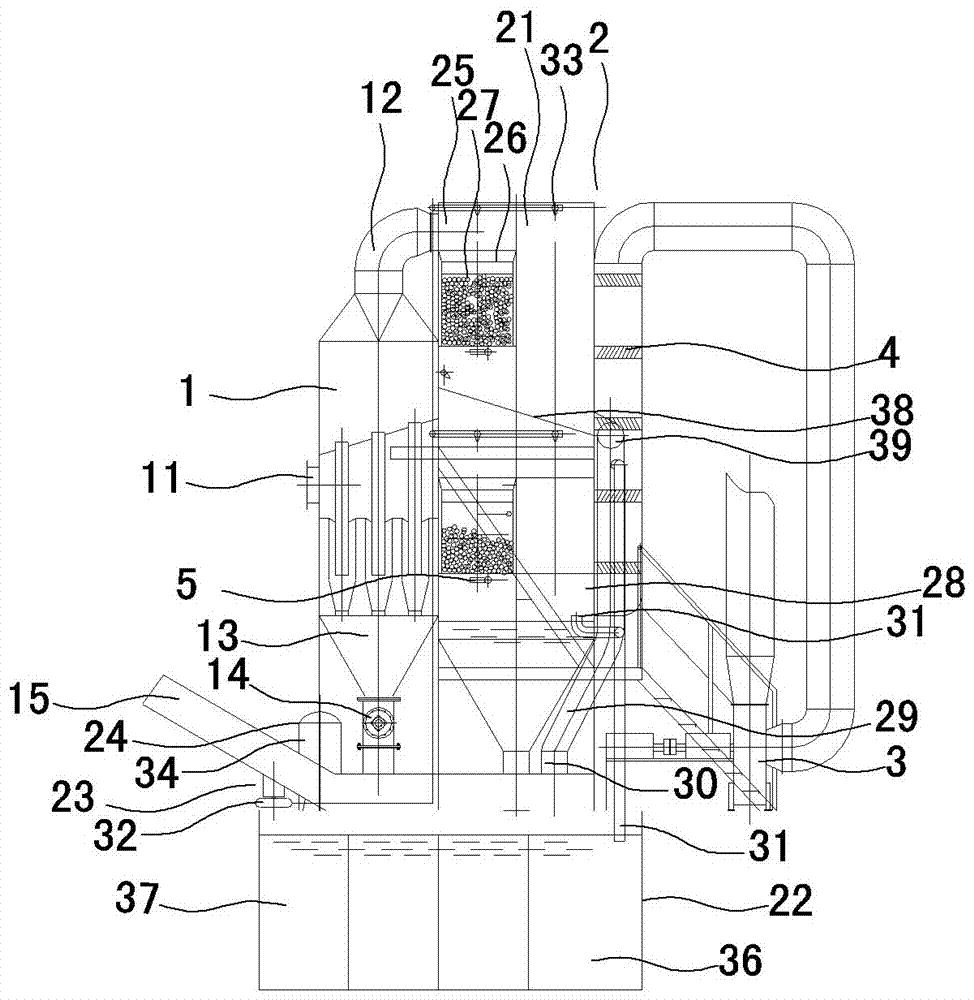

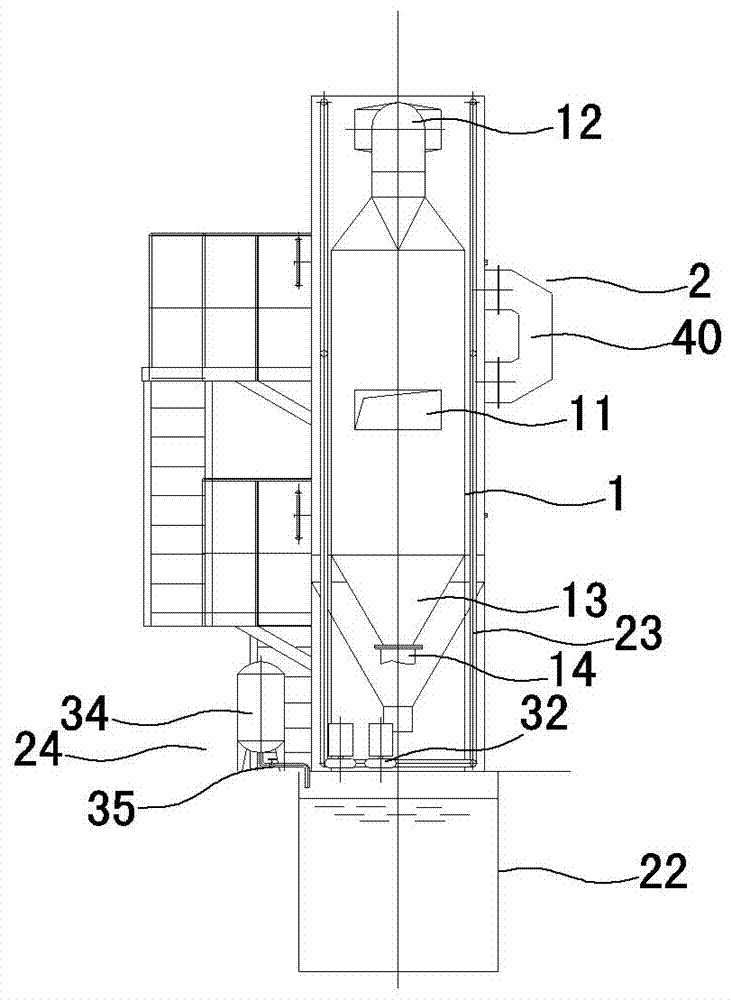

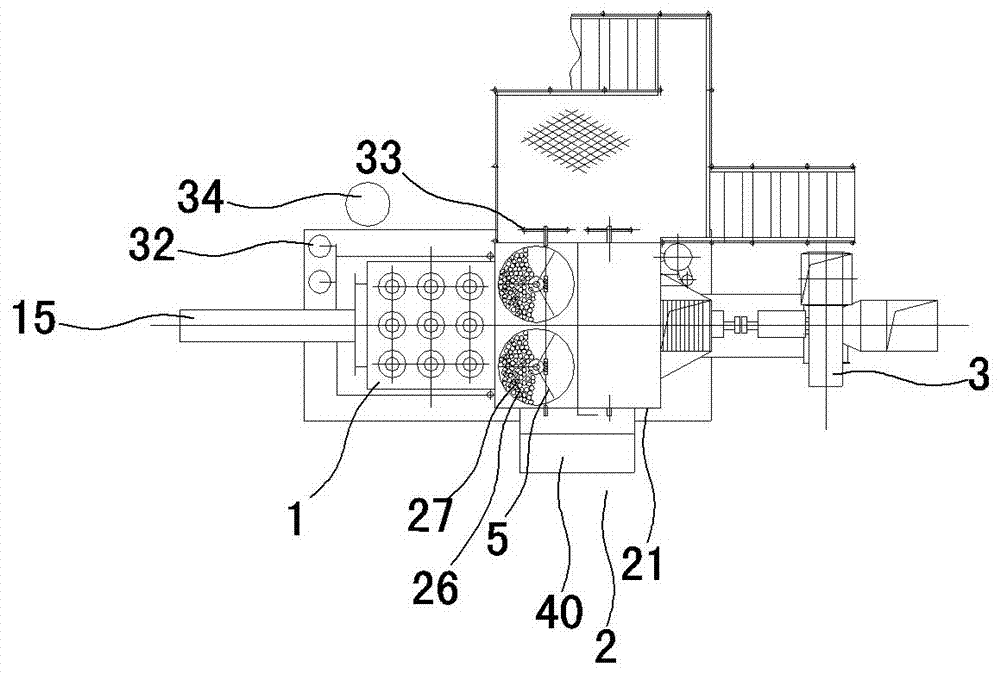

[0010] like figure 1 , figure 2 , image 3 As shown, it includes a dust removal device 1, a desulfurization and denitration device 2 and an induced draft fan 3. The dust removal device 1 is provided with a total air inlet 11 along the tangential direction of the side wall, a total air outlet 12 on the upper part, and an ash collecting hopper 13 at the bottom. The outlet of the ash collecting hopper 13 is provided with a cyclone multi-tube dust collector with an ash discharge valve 14. The desulfurization and denitrification device 2 is composed of a desulfurization and denitrification tower 21, a circulating sedimentation tank 22, a urea spray mechanism 23 and a dosing mechanism 24. The cyclone multi-tube The air outlet 12 of the dust collector is communicated with the flue gas inlet 25 above the desulfurization and denitrification tower 21. The circulating sedimentation tank 22 is located below the desulfurization and denitrification tower 21. The desulfurization and denitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com