STL-model-based material removal algorithm in numeral control machining geometric simulation

A model and algorithm technology, applied in the field of virtual CNC machining, can solve problems such as poor real-time performance, low machining efficiency, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

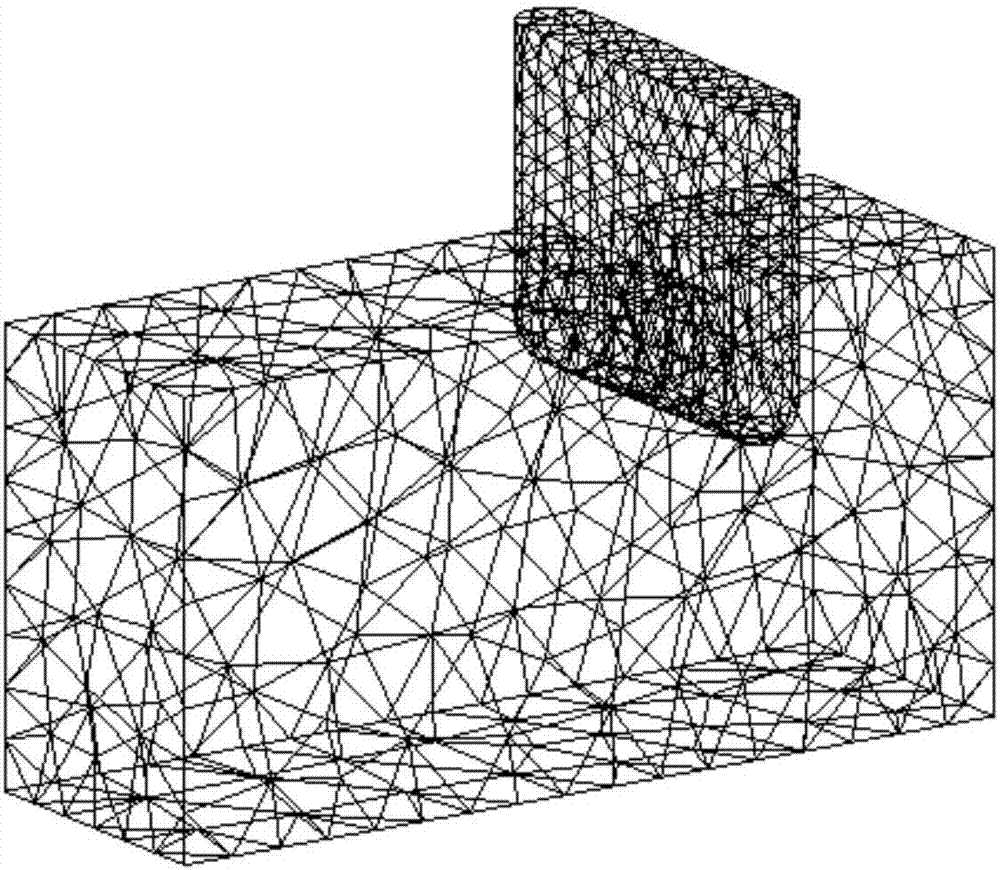

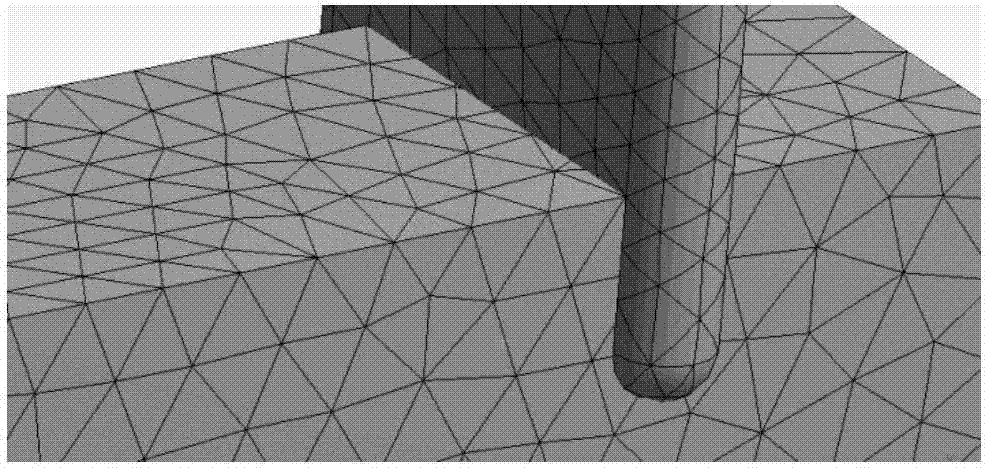

[0038] Such as figure 1 As shown, the present invention provides a material removal algorithm based on the STL model in the geometric simulation of numerical control machining. Line segments and intersection rings; the workpiece to be machined and the sweeping tool model are both in STL format, and a boundary line will be generated when the sweeping tool cuts the workpiece. The overall structure is as follows figure 2 shown, from image 3 It can be seen that the boundary line produced by the tool sweep body cutting the workpiece is a closed loop; the closed loop divides the processed workpiece and the tool sweep body into two parts. Concrete steps of the present invention are as follows:

[0039] 1) Convert the processed workpiece and tool sweep body generated by CAD into STL format, as shown in the attached Figure 4a , Figure 4b , Figure 5a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com