Phase-change material service life testing system

A phase change material, life testing technology, applied in the investigation phase/state change and other directions, can solve the problems of affecting the formation of the primary crystal nucleus of the phase change material, affecting the accuracy of the test results, and the deviation of the phase change point from the actual value. The effect of uneven heating, reasonable structure and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

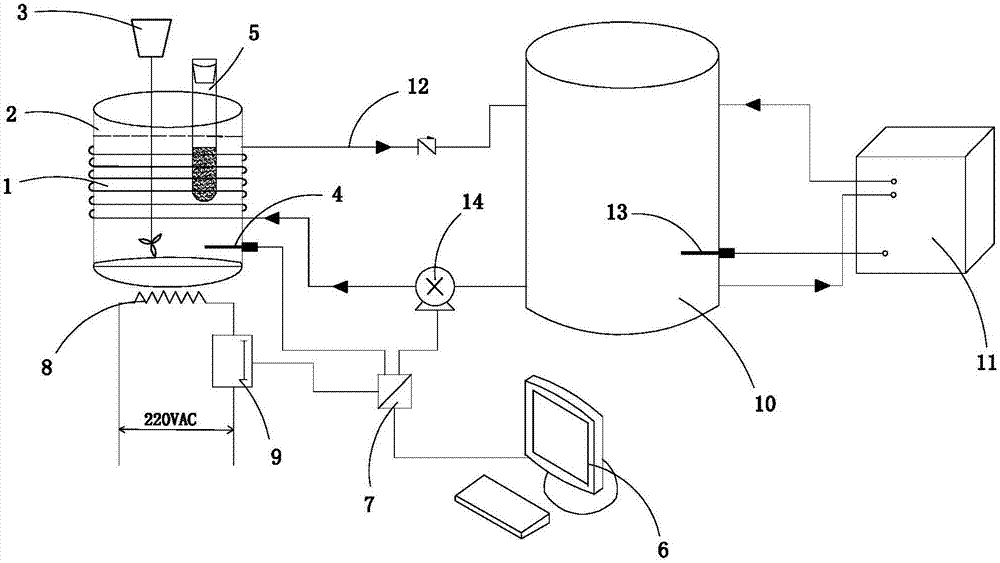

[0012] The specific structure of the phase change material service life testing system in the present invention is described below in conjunction with the accompanying drawings:

[0013] A phase change material life testing system, its structure is as follows figure 1 Shown, comprise oil bath 1, test tube 5, electric heating device 8, cooling device and computer 6, described oil bath 1 comprises the pan body 2 that is filled with heat conduction medium, is used for stirring described heat conduction medium (as silicone oil, Water, etc.) stirrer 3 and the first temperature sensor 4 for detecting the temperature of the heat transfer medium; the inside of the test tube 5 is filled with a phase change material, and the test tube 5 is located in the pot body 2 and fixed on a fixed bracket Above; the electric heating device 8 is used to heat the heat-conducting medium in the oil bath 1; the cooling device is used to cool the heat-conducting medium in the oil bath 1; the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com