Stiffened plate shear test loading device

A technology of loading device and stiffened plate, which is applied in the direction of measuring device, using stable shear force to test the strength of materials, instruments, etc., can solve the problem of uneven stress on the reinforcement section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The system of the patent of the present invention will be further described below with reference to the accompanying drawings.

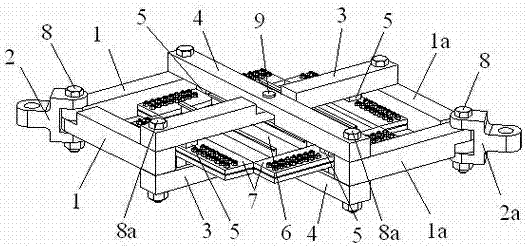

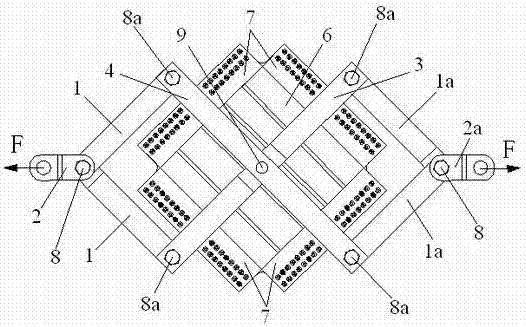

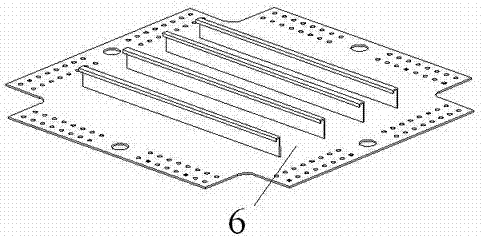

[0020] figure 1 , 2 , 4, 5, 6, 7, and 8 show a structural diagram of a loading device for a stiffened plate shearing experiment. In the figure, this loading device for stiffened plate shear experiment includes two first pull plates 1, two second pull plates 1a, a first loading lug 2, a second loading lug 2a, two first Slide rail 3, two second slide rails 4, four slider structures 5 and eight reinforcement plates 7, dimensions of the first pull plate 1 and the second pull plate 1a, the first slide rail 3 and the second slide rail 4 same.

[0021] The first loading lug 2 is hingedly connected with one end of the two first pull plates 1 by a first pin bolt 8, and the second load lug 2a is connected by another first pin bolt 8 and two second pull plates 1a. One end of the hinge connection. The top of the other ends of the two first pull plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com