Equipment for catalytic cracking and combustion of waste rubber and plastic of cement kiln head

A technology for catalytic cracking and waste rubber, which is applied in the direction of combustion type, cement production, combustion method, etc., to achieve the effect of simple equipment and low utilization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

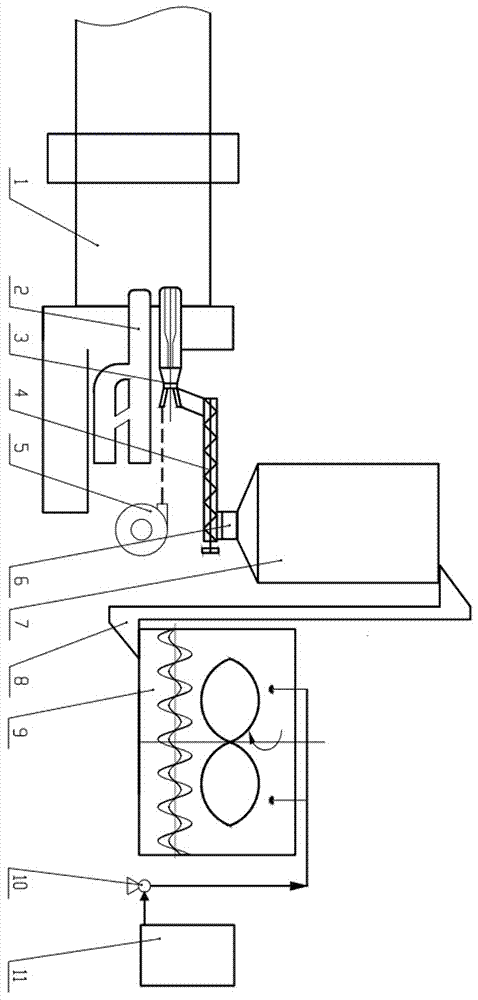

[0024] refer to figure 1 , a cement kiln kiln head catalytic cracking burning waste rubber or plastic equipment, including pulverized coal burner 2, waste fuel swirl burner 3, lock air feeder 4, high-pressure fan 5, feeder 6, Waste fuel bin 7, conveyor I 8, homogenizer 9, feed pump 10 and catalytic cracking oxidant storage tank 11, the feed pump 10 is connected to the liquid outlet of catalytic cracking oxidant storage tank 11 through different pipelines , the atomizing spray liquid inlet pipe of homogenizer 9 is connected, and the discharge end and the feed end of described conveyor I8 are respectively connected with the feed inlet of modified waste fuel bunker 7 and the discharge port of homogenizer 9. The bottom discharge port of the waste fuel bin 7 is connected with the feeder 6, the feeder 6 is connected with the wind lock feeder 4, and the wind lock feeder 4 is connected with the waste The feed port of the fuel swirl burner 3 is connected, and the high-pressure blower ...

Embodiment 2

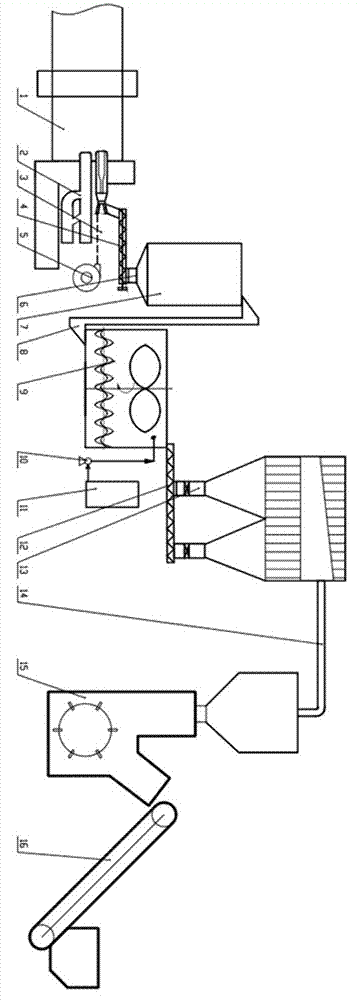

[0029] refer to figure 2 , a cement kiln kiln head catalytic cracking burning waste rubber or plastic equipment, including pulverized coal burner 2, waste fuel swirl burner 3, lock air feeder 4, high-pressure fan 5, feeder 6, Waste fuel bin 7, conveyor I 8, homogenizer 9, metering pump 10, catalytic cracking oxidant storage tank 11, batching and feeding device 12, plastic / rubber shredded waste storage bin 13, conveyor II 14, crushing The device 15 and the conveyor III16, the discharge end of the conveyor III16 is connected to the feed port of the crushing device 15, the discharge end and the feed end of the conveyor II14 are respectively connected to the plastic / rubber shredded waste storage bin The feeding port of 13 and the discharging port of crushing device 15 are connected, and the batching and feeding device 12 is respectively connected with the bottom discharge port of plastic / rubber crushed waste storage bin 13 and the feeding port of homogenizer 9, The meter feed pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com