A UV-assisted electrostatic atomization forming system and preparation method of titanium dioxide coating

An electrostatic atomization, titanium dioxide technology, applied in surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of poor antibacterial persistence and fast silver ion release speed, and achieve biocompatibility and rich applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

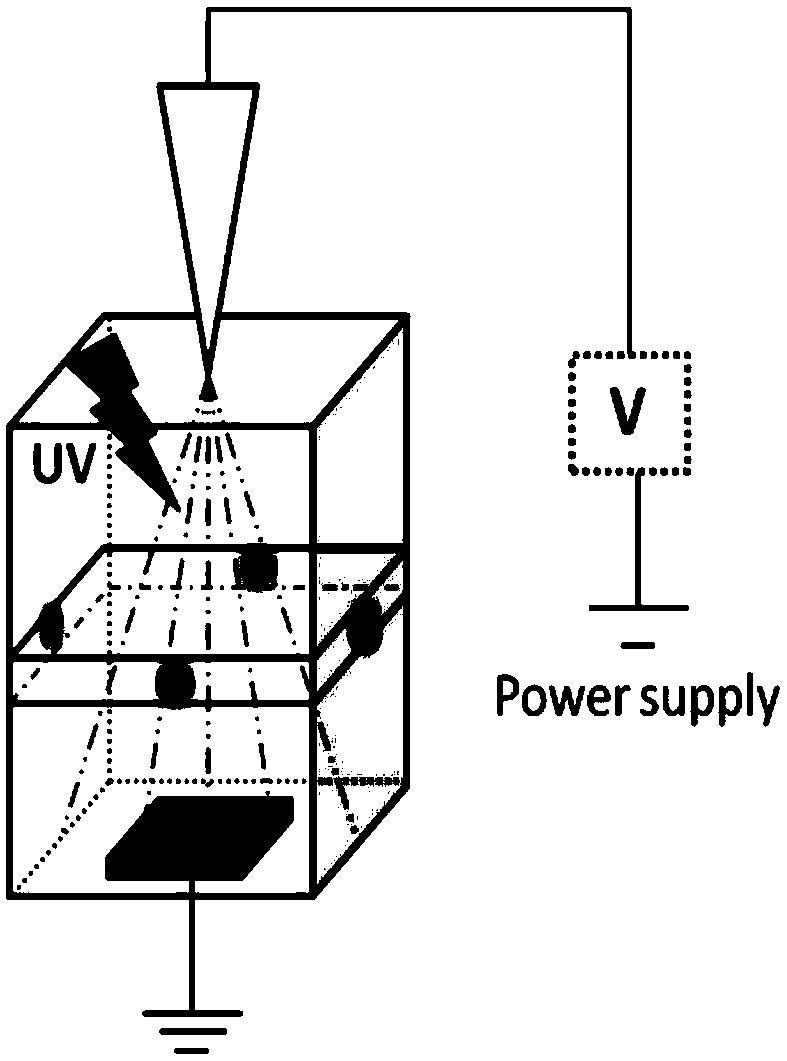

Method used

Image

Examples

example 1

[0023] 1) Add 0.5mol / L Na 2 SiO 3 and 0.05mol / L NaOH mixed solution as electrolyte;

[0024] 2) With the cleaned titanium sheet as the anode and the platinum sheet as the cathode, the titanium sheet was micro-arc oxidized for 2 minutes at 220V, 1min; 235V, 1min sub-voltage;

[0025] 3) Dry the amorphous titanium dioxide coating material obtained in step 2 micro-arc oxidation in an oven at 80°C, take it out after drying, put it into a sintering furnace for heat treatment, increase the temperature at a rate of 5°C / min to 450°C, and keep it for 3 to 4 hours to remove organic ingredients.

[0026] 4) Under dark conditions, immerse the micro-arc oxidation titanium dioxide coating material after the heat treatment in step 3 into a 0.1M silver nitrate solution for 4 hours.

[0027] 5) Wash and dry the titanium sheet treated in step 4, and irradiate it with ultraviolet light (wavelength ~250nm) for 30 minutes to obtain a titanium dioxide nanostructure coating with biocompatibility ...

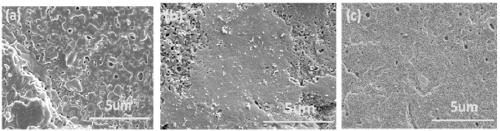

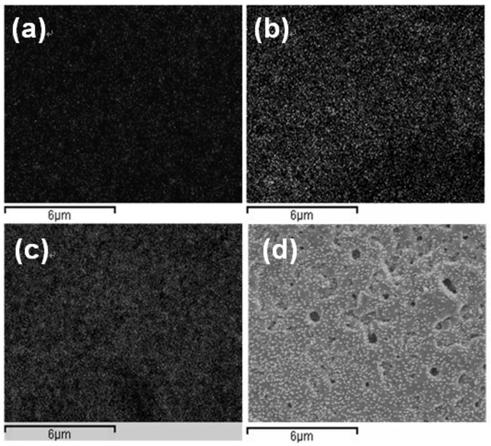

Embodiment 1

[0028] The nano-Ag particle-doped micro-arc oxidation titanium dioxide coating structure that embodiment 1 obtains is as follows figure 2 (a) shown.

example 2

[0030] Considering that the loading of nano-Ag particles on the micro-arc oxidation titanium dioxide coating obtained by the method of Example 1 is not uniform enough and stable. Therefore, the method was improved, and the micro-arc oxidation titanium dioxide coating doped with nano-Ag particles was prepared after surface modification of the material.

[0031] 1) Add 0.5mol / L Na 2 SiO 3 and 0.05mol / L NaOH mixed solution as electrolyte;

[0032] 2) With the cleaned titanium sheet as the anode and the platinum sheet as the cathode, the titanium sheet was micro-arc oxidized for 2 minutes at 220V, 1min; 235V, 1min sub-voltage;

[0033] 3) Dry the amorphous titanium dioxide coating material obtained in step 2 micro-arc oxidation in an oven at 80°C, take it out after drying, put it into a sintering furnace for heat treatment, increase the temperature at a rate of 5°C / min to 450°C, and keep it for 3 to 4 hours to remove organic ingredients.

[0034] 4) The titanium dioxide coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com