Method for cleaning segment defect treatment in stainless steel cold rolling acid pickling process

A defect treatment and cleaning section technology, applied in the field of metallurgy, can solve the problems of rubber pressing defects, affecting product quality, black foreign matter adhesion, etc., achieve good decompression effect, excellent oil resistance, and improve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0019] The method for treating defects in the cleaning section in the stainless steel cold-rolled pickling process of the embodiment of the present invention includes:

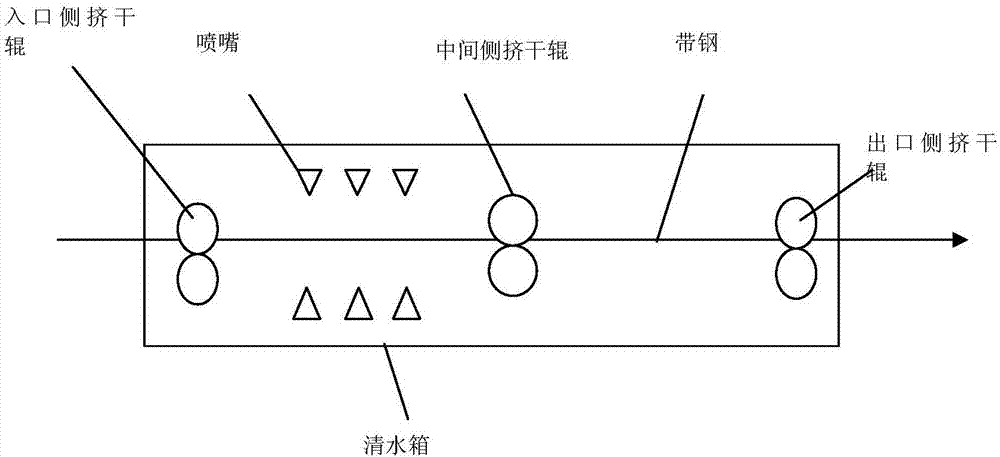

[0020] In the final cleaning process, the strip is cleaned with at least three sets of rollers in the cleaning box, such as figure 1 As shown, the three groups of rollers are the entrance side squeeze roller, the middle side squeeze roller and the exit side squeeze roller respectively, wherein the material of the exit side squeeze roller is polyurethane rubber. Further, the squeeze rollers on the entrance side and the squeeze rollers on the middle side are both equipped with clear water cleaning, and the cleaning of the squeeze rollers on the exit side is squeeze cleaning. Further, a spray beam is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com