Device, system and method for replacing furnace column of coking furnace

A furnace column and coke oven technology, which is applied in the field of equipment maintenance tools for industrial and mining enterprises, can solve problems such as low efficiency, unsafe hoisting, and high cost, and achieve the effect of simple method, convenient operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

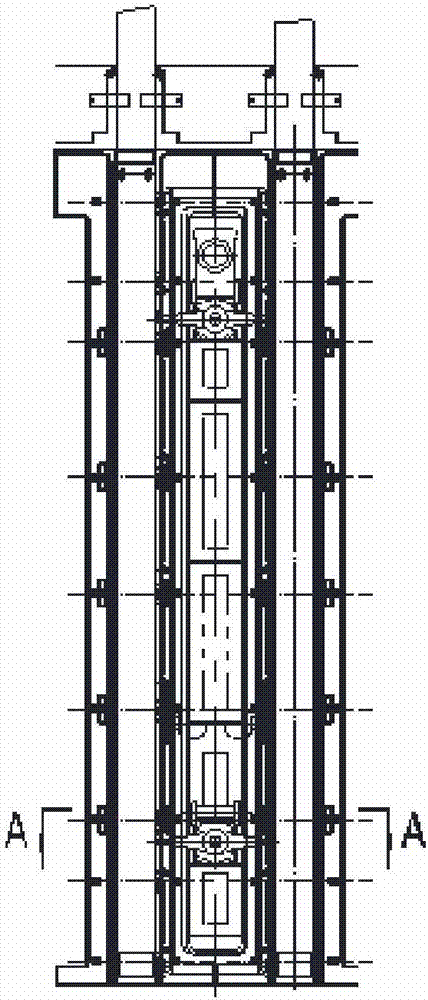

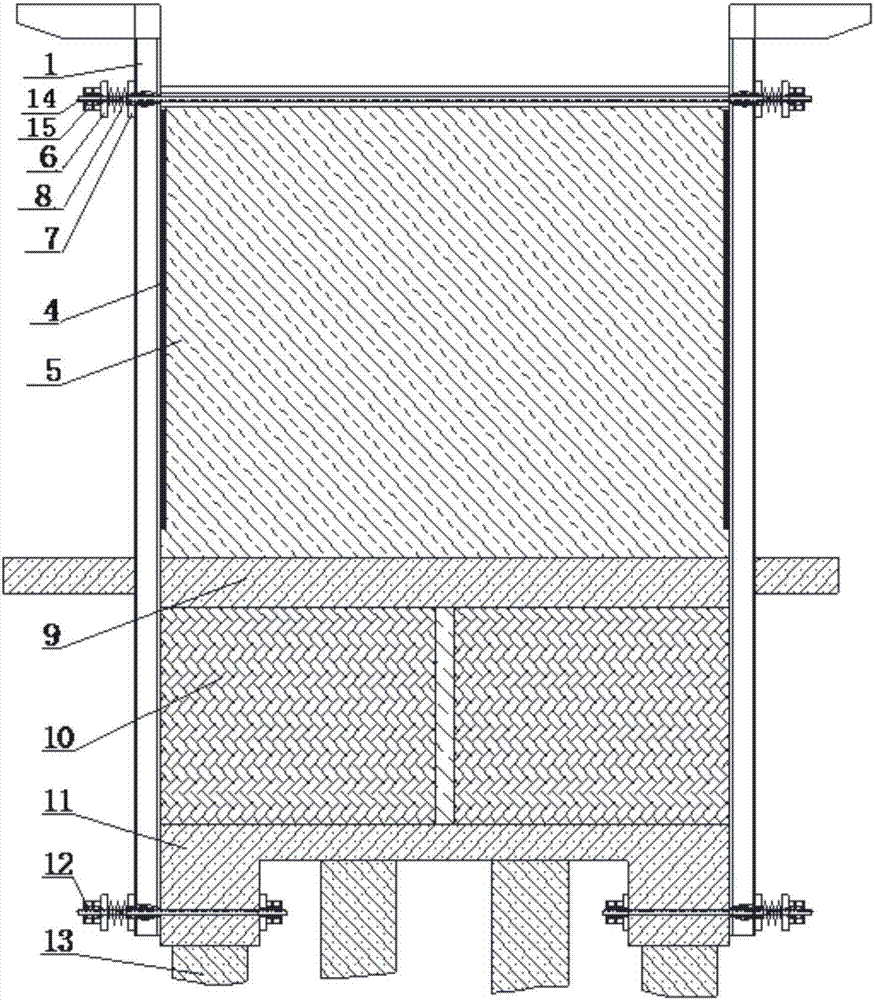

[0064] Specific embodiment one, such as Figure 4 , Figure 5 Shown:

[0065] The device for coke oven column replacement includes a fixing unit, a limiting unit and a bracket, wherein the fixing unit includes two, symmetrically arranged at both ends of the bracket, and each fixing unit includes a rib plate 29 and one end of the rib plate 29 The two clamping plates are respectively the first clamping plate 22 and the second clamping plate 24, wherein the second clamping plate 24 is arranged on one end of the rib plate 29, and the first clamping plate 22 and the second clamping plate 24 are arranged on the rib On the plate 29, a U-shaped slot is formed, and a locking screw 23 is arranged on the first clamping plate 22. The U-shaped slot formed by the two clamping plates is engaged on the furnace column. After the locking screw 23 is tightened, the fixing unit is fixed. on the stove column.

[0066] The limiting unit is arranged in the middle of the bracket, and the limiting ...

specific Embodiment 2

[0067] Specific embodiment two, such as Figure 6 to Figure 15 Shown:

[0068] The device for coke oven column replacement includes a fixing unit, a limiting unit and a bracket, wherein the fixing unit includes two, symmetrically arranged at both ends of the bracket, and a detachable connecting piece is arranged between the fixing unit and the bracket; each The fixing unit includes a rib plate 29 and two clamp plates arranged at one end of the rib plate 29, namely a first clamp plate 22 and a second clamp plate 24, wherein the second clamp plate 24 is arranged at one end of the rib plate 29, and the first clamp plate 24 is arranged at one end of the rib plate 29. The clamping plate 22 and the second clamping plate 24 are arranged on the rib plate 29 in parallel to form a U-shaped clamping groove. The first clamping plate 22 is provided with a locking screw 23, and the U-shaped clamping groove formed by the two clamping plates is engaged with the furnace column After the locki...

specific Embodiment 3

[0073] Specific embodiment three, such as Figure 16 to Figure 24 Shown:

[0074] Coke oven column replacement system, the system includes a furnace column replacement device, a furnace column hoisting device, a furnace column fixing device, a furnace column disassembly device, and a protective plate fixing device, wherein the furnace column hoisting device includes a winch and a lifting beam 33, wherein The winch has a fixed pulley 34 and a wire rope 35, the fixed pulley 34 is fixed on the suspension beam 33, one end of the wire rope 35 bypassing the fixed pulley 34 has a hook, and the other end is connected with the drive motor of the winch, and the replaced furnace column is hoisted on the hook , hoisting machine control wire rope 35 lifts or lowers the furnace column that changes. Since the top of the furnace column has a gas collecting pipe 36, the winch is set away from the gas collecting pipe 36, which avoids the disadvantages of crane disassembly.

[0075] The furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com