Mounting method of locking device for platform type crushed stone laying and leveling ship

The technology of a locking device and installation method is applied in the direction of transportation and packaging, special-purpose ships, ships, etc., and can solve the problems of inability to adopt vertical lifting alignment installation, high difficulty of installation, and narrow installation position inside the lifting frame, etc., to achieve Improving construction efficiency, simplifying procedures, and avoiding the effect of crooked pulling and slanting hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

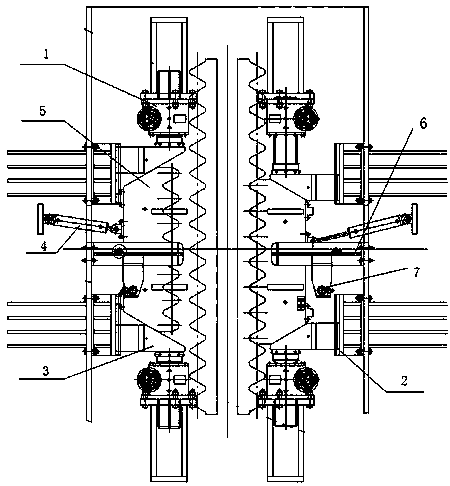

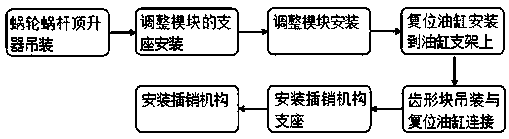

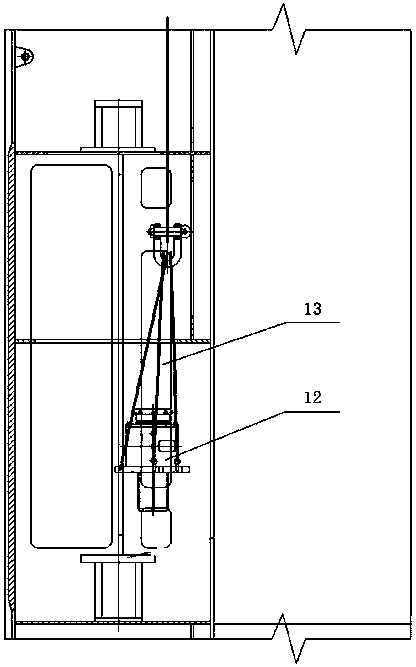

[0042] Such as figure 1 As shown, the specific implementation method adopts the following technical scheme: a method for installing the locking device of a platform-type gravel laying and leveling ship, the innovation point of which is to distribute and install the parts of the locking device to adapt to the operation in a small space, The locking device includes a worm gear jack 1, a wedge support 2, an adjustment wedge 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com