A kind of organic-inorganic hybrid nano-compatibilizer based on poss and its preparation and application

A compatibilizer and hybridization technology, which is applied in the field of POSS-based organic-inorganic hybrid nano-compatibilizer and its preparation and application, can solve problems such as poor compatibility, and achieve the effect of improved scratch resistance and strong resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of PP-poss-MAH compatibilizer: the mass fractions of the system are: polypropylene: 94.9%, maleic anhydride: 4%, initiator: 0.3%, octavinyl POSS: 0.8%.

[0026] Weigh 47.45g of polypropylene, 2g of maleic anhydride, 0.15g of dicumyl peroxide, and 0.4g of octavinyl POSS, and mix them in a high-speed mixer at 1200r / min for 5min, then at 180°C with a rotation speed of 90r / min Extrude the masterbatch in a special extruder, and dry the masterbatch at 70°C for 8 hours, the color of the yellow particles will become lighter.

Embodiment 2

[0028] Purification of PP-poss-MAH compatibilizer: Weigh 1g of masterbatch into a 250ml round bottom flask, add 100ml of xylene, heat and reflux at 120°C for 30min, wait until it is completely dissolved, transfer the solution to an unheated In 100ml of acetone, a white emulsion was formed, which was subjected to static precipitation for 3 hours, and filtered with suction to obtain a white yellowish solid, which was dried at 70°C for 8 hours.

Embodiment 3

[0030] Application of PP-poss-MAH compatibilizer in PP / PA long glass fiber composites: the mass fractions of the system composition are: the amount of compatibilizer 3%, PP: 59%, PA: 9%, long glass fiber : 29%.

[0031] Weigh 3g of compatibilizer, 59g of polypropylene, 9g of polyamide and 29g of long glass fiber and mix them in a high-speed mixer at 1200r / min for 5min, then extrude the masterbatch in an extruder at 200°C with a speed of 220r / min .Make standard splines for mechanical performance testing.

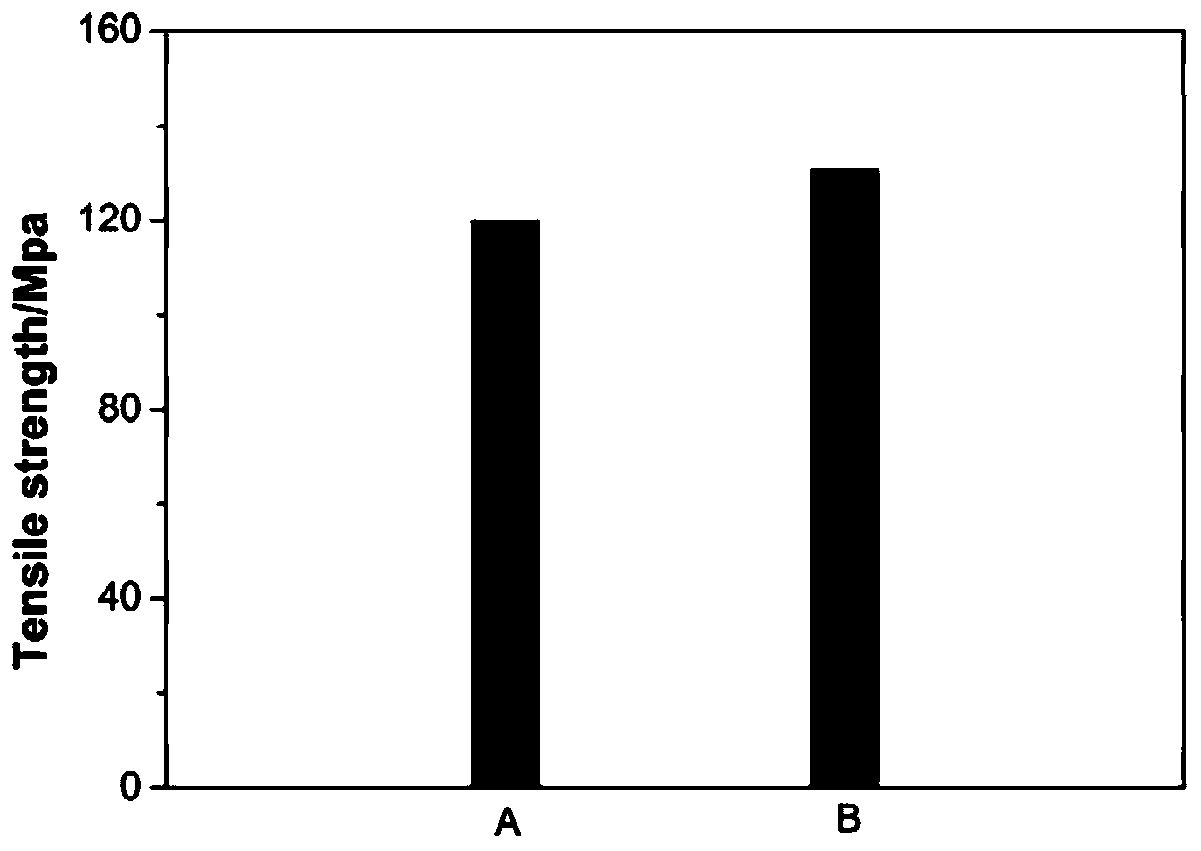

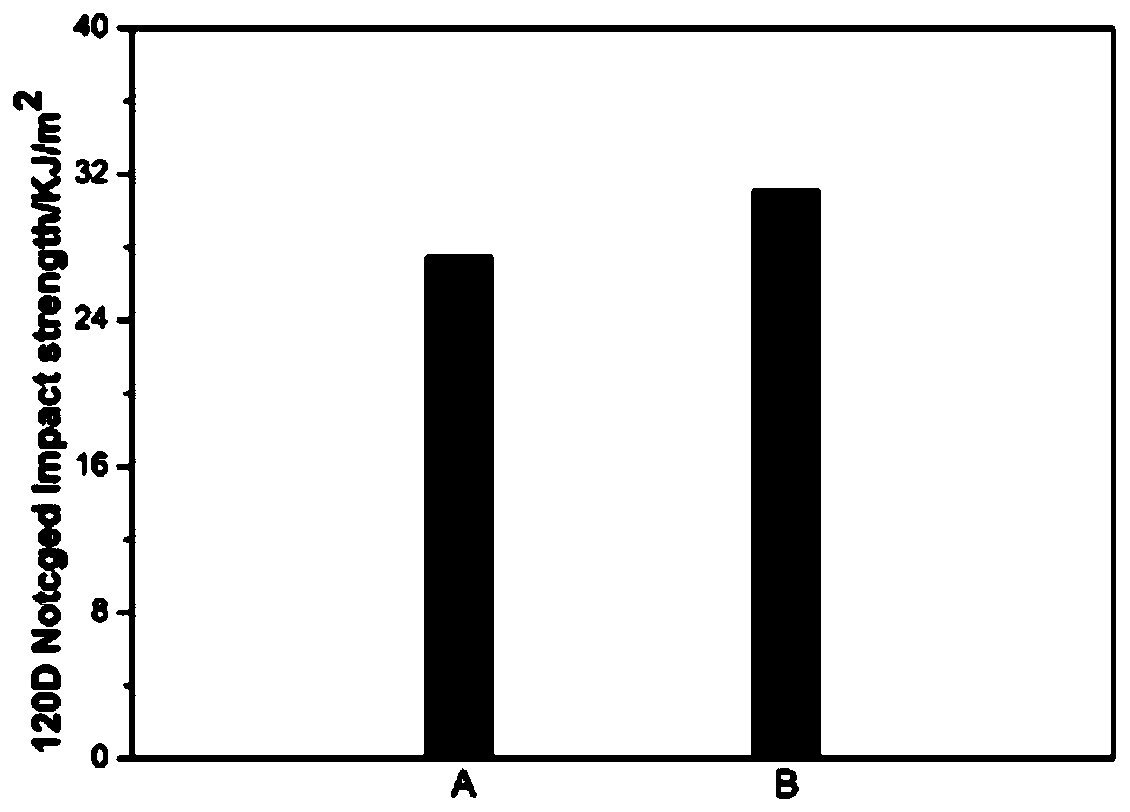

[0032] Tensile properties are tested according to ISO 527 standard ( figure 1 ), A in the figure is the tensile strength of the composite material obtained using the PP-g-MAH compatibilizer, and its value is 120Mpa, and B is the tensile strength of the composite material obtained with the PP-poss-MAH compatibilizer, and its value is 131Mpa; impact performance is tested according to ISO 180 standard ( figure 2 ); A in the figure is the impact strength of the composite mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com