Preparation method for high-purity natural garlic ajoene

A high-purity technology of ajoene, which is applied in the field of preparation of high-concentration natural garlic ajoene, can solve the problems of high cost, large amount of preparation raw materials, difficulty in breaking through the bottleneck of purity improvement technology, etc., so as to reduce consumption, save raw materials, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Take 10Kg of garlic from Shandong, peel it, crush it to a particle size of 2mm, add 2Kg of 80% ethanol, stir evenly, and leave it to ferment for 2 days.

[0031] 2. Add 25Kg of 85% ethanol to the above fermented product, ultrasonically extract for 1 hour, filter, and concentrate the filtrate under reduced pressure at a temperature of 55-75°C to remove ethanol in the filtrate to obtain an ultrasonic extract.

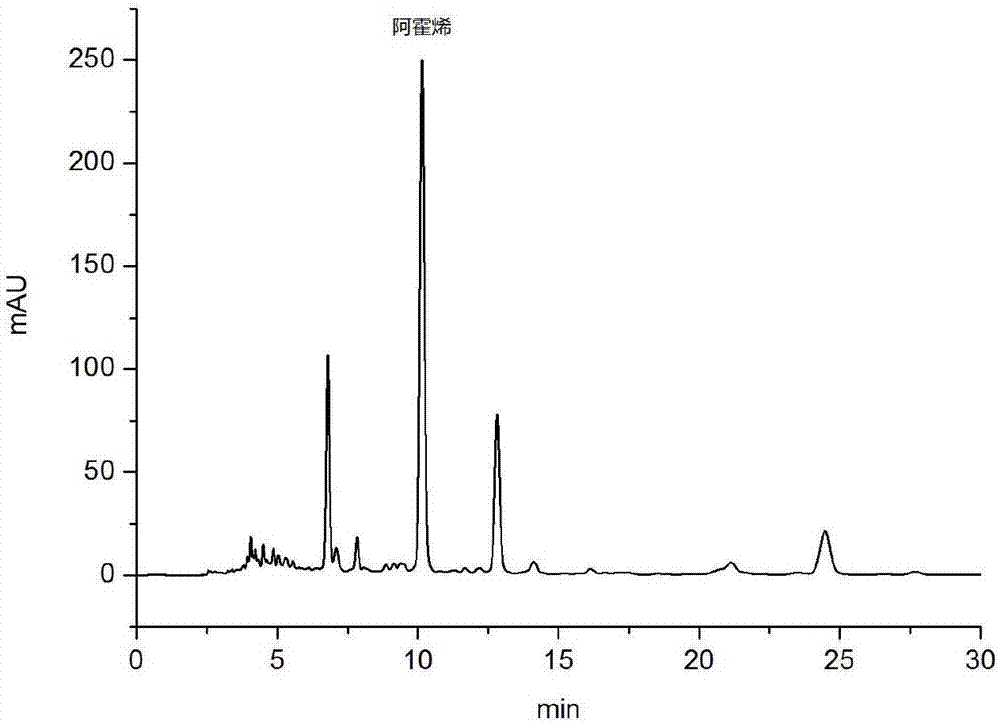

[0032] 3. Place the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, the extraction pressure is adjusted to 20Mpa, the extraction temperature is 50°C, the pressure of the separation kettle 1 is 15Mpa, and the temperature of the separation kettle 1 is 60°C. When the extraction and separation conditions meet the setting requirements, the circular extraction is started for 1.5 hours, and samples are collected from the separation tank II. Such as figure 1 Shown is supercritical CO 2 High performance liquid chromato...

Embodiment 2

[0037] 1. Take 10Kg of garlic produced in Jilin, peel it, crush it to a particle size of 10mm, add 0.5Kg of 95% ethanol, stir evenly, and let it stand for fermentation for 2 days.

[0038] 2. Add 40Kg of 60% ethanol to the above fermented product each time, ultrasonically extract 3 times, each time for 2h, filter, and the filtrate is concentrated under reduced pressure at a temperature of 55-75°C to remove ethanol in the filtrate to obtain an ultrasonic extract.

[0039] 3. Place the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, adjust the extraction pressure to 30Mpa, the extraction temperature is 40°C, the pressure of the separation kettle I is 18Mpa, and the temperature of the separation kettle I is 70°C. When the extraction and separation conditions meet the setting requirements, the circular extraction is started for 2.5 hours, and samples are collected from the separation tank II.

[0040] 4. Supercritical CO 2 The ex...

Embodiment 3

[0044] 1. Take 10Kg of garlic from Ningxia, peel it, crush it to a particle size of 0.5mm, add 3Kg of 60% ethanol, stir evenly, and let it stand for fermentation for 2 days.

[0045] 2. Add 10Kg of 95% ethanol to the above fermented product each time, ultrasonically extract twice, each time for 0.5h, filter, and the filtrate is concentrated under reduced pressure at a temperature of 55-75°C to remove ethanol in the filtrate to obtain an ultrasonic extract.

[0046] 3. Place the above ultrasonic extract in supercritical CO 2 In the extraction kettle of the extraction device, the extraction pressure was adjusted to 15Mpa, the extraction temperature was 70°C, the pressure of the separation kettle 1 was 9Mpa, and the temperature of the separation kettle 1 was 45°C. When the extraction and separation conditions meet the setting requirements, the circular extraction is started, and the extraction is 0.5h, and the sample is collected from the separation tank II.

[0047] 4. Supercriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com