Mineral matter concentrate rich in trace elements, and preparation method and application thereof

A technology of trace elements and concentrates, applied in applications, chemical instruments and methods, food science, etc., can solve the problems of low product quality, high energy consumption, difficult operation, etc., and achieve high product quality, simple preparation process, and reliable highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

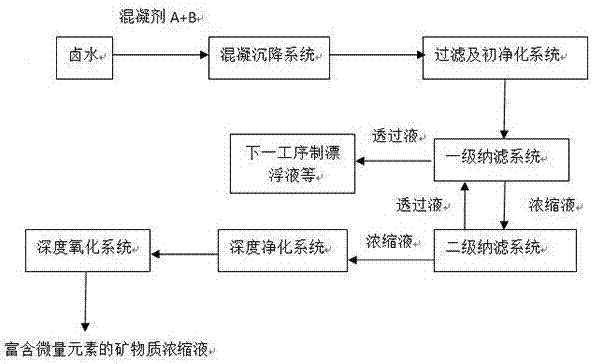

[0038] Use brine as raw material to produce mineral concentrates rich in trace elements, such as figure 1 shown, including the following steps:

[0039] 1) When the brine is pumped into the first-stage coagulation tank, the coagulant A+B is mixed through the mixer, and the addition amount is 20mg / L. Most of the heavy metals were removed by coagulation and sedimentation. Coagulant A+B is polyferric silicate (PFSI) + polyaluminum ferric chloride (PAFC). The weight percentage of coagulant added is: polyferric silicate accounts for 40%, and polyaluminum ferric chloride accounts for 60%.

[0040] 2) The brine after coagulation and settlement is injected into the three-stage filtration system with the pump, and the pore size of the filter element decreases step by step to less than 0.01µm, and the maximum operating pressure is 0.3Mpa, and then passes through the pre-purification device to remove part of the organic matter and heavy metal ions in the seawater. The operating pressur...

Embodiment 2

[0047] The difference with Example 1 is that the amount of coagulant A+B added to the mixer in this Example 2 is 30 mg / L, and the maximum operating pressure of the nanofiltration membrane in step 3) is 3.5 MPa. When TDS (dissolved The total amount of sexual solids) reached 215000mg / L

[0048] , the concentrated solution can be pumped out. After testing, the main ion concentration in the mineral concentrated solution is Ca 2+ 150mg / L, Mg 2+ 31000mg / L, K + 3000mg / L, Cl - 12000mg / L, other heavy metal ions lead ions ≤0.005 mg / L, cadmium ions ≤0.01 mg / L, arsenic ions ≤0.05 mg / L, NO 2- The content is effectively reduced to 0.005mg / L.

Embodiment 3

[0050] The difference from Example 1 is that the amount of coagulant A+B added to the flow mixer in Example 2 is 40 mg / L, and the maximum operating pressure of the nanofiltration membrane in step 3) is 3.7 MPa. When TDS (dissolved When the total amount of sexual solids) reaches 230000mg / L, the concentrated solution can be pumped out. After testing, the main ion concentration in the mineral concentrated solution is Ca 2+ 200mg / L, Mg 2+ 35000mg / L, K + 3500mg / L, Cl - 8000mg / L, other heavy metal ions lead ions ≤0.005 mg / L, cadmium ions ≤0.01 mg / L, arsenic ions ≤0.05mg / L, NO 2- The content is effectively reduced to 0.005mg / L. Coagulant A+B is polyferric silicate (PFSI) + polyaluminum ferric chloride (PAFC). The weight percentage of coagulant added is: polyferric silicate accounts for 40%, and polyaluminum ferric chloride accounts for 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com