A method for preparing graphene based on laser exfoliation

A technology of laser exfoliation and graphene, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult mass production of graphene and excessive ablation of graphene structure, so as to avoid excessive ablation and prepare The process is clean and pollution-free, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

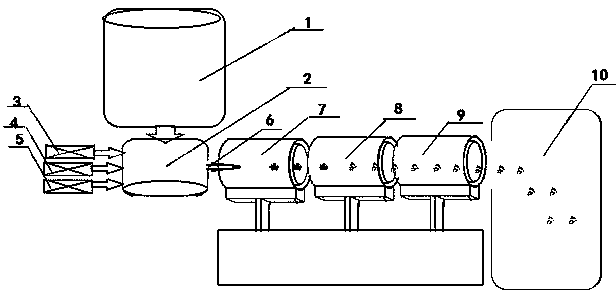

[0032] A method for preparing graphene based on laser exfoliation, combined with attached figure 1 Explain the graphene exfoliation process:

[0033] (1) Prepare sodium chloride into a supersaturated salt solution in water at 80-100°C, then soak the graphite powder and the supersaturated salt solution for more than 24 hours, so that the saturated salt solution can fully penetrate and insert into the graphite layer, and then filter out liquid, dry to obtain intercalated graphite;

[0034] (2) Grind and disperse the intercalated graphite obtained in step (1) and send it into the high-pressure tank (1). The pressure of the high-pressure tank is maintained at 0.5-0.6 MPa. The intercalated graphite is continuously sprayed into the mixing chamber (2) of the jet machine at a stable flow rate and velocity, and at the same time, three streams of compressed air with different pressures are injected into the chamber of the jet machine in the same direction, of which the first stream of co...

Embodiment 2

[0041] A method for preparing graphene based on laser exfoliation:

[0042] (1) Prepare sodium sulfate into a supersaturated salt solution in water at 80-100°C, then soak the graphite powder and the supersaturated salt solution for more than 24 hours, so that the saturated salt solution can fully penetrate and insert between the graphite layers, and then filter out the liquid , dry to obtain intercalated graphite;

[0043] (2) Grind and disperse the intercalated graphite obtained in step (1) and send it into a high-pressure tank. The pressure of the high-pressure tank is maintained at 0.5-0.6 MPa. Under the pressure of the high-pressure tank, the intercalated graphite is controlled by a valve Continuously spray into the mixing chamber of the jet machine with a stable flow rate and flow rate, and at the same time inject three streams of compressed air with different pressures into the chamber of the jet machine in the same direction, of which the pressure of the first stream of...

Embodiment 3

[0049] A method for preparing graphene based on laser exfoliation:

[0050] (1) Prepare potassium carbonate into a supersaturated salt solution in water at 80-100°C, then soak the graphite powder and the supersaturated salt solution for more than 24 hours, so that the saturated salt solution can fully penetrate and insert the graphite layer, and then filter out the liquid , dry to obtain intercalated graphite;

[0051] (2) Grind and disperse the intercalated graphite obtained in step (1) and send it into a high-pressure tank. The pressure of the high-pressure tank is maintained at a stable range of 0.8-1.0 MPa. Under the pressure of the high-pressure tank, the intercalated graphite is controlled by a valve. Continuously spray into the mixing chamber of the jet machine with a stable flow rate and flow rate, and at the same time inject three streams of compressed air with different pressures into the chamber of the jet machine in the same direction, of which the pressure of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com