A milling and drilling compound processing tool

A compound machining and cutting tool technology, applied in milling cutters, manufacturing tools, drilling tool accessories, etc., can solve the problems of unsuitable processing of blind holes and long drilling parts, and achieves improvement of cutting efficiency, suppression of delamination, and increase of diameter. effect on the component

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

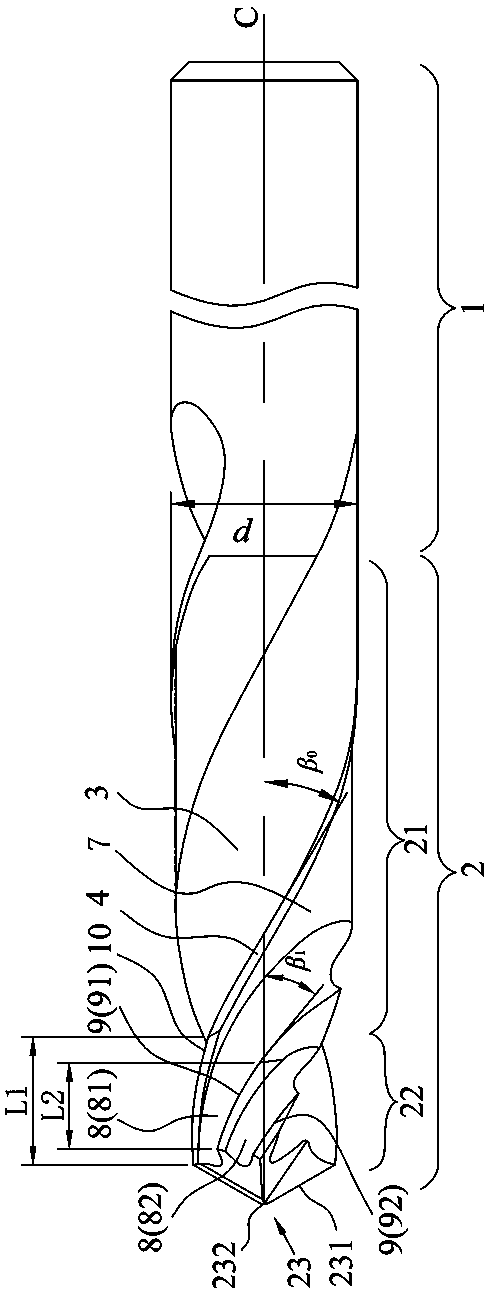

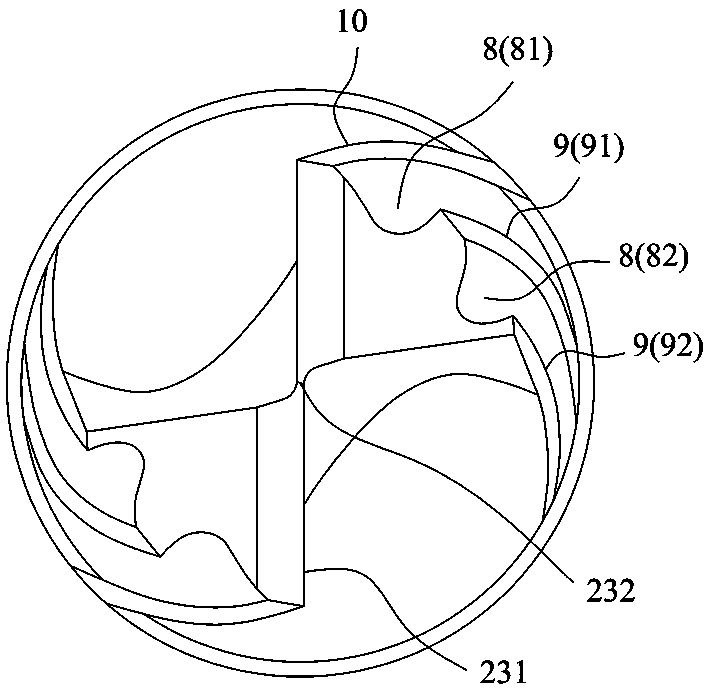

[0028] Such as Figure 1 to Figure 3 As shown, the milling and drilling compound processing tool (twist drill) of the present embodiment includes a cutter body 2 and a handle 1, and the cutter body 2 includes a drilling part 23, a milling part 22 and a guide part 21 arranged in sequence, and the guide part 21 and the guide part 21 are arranged in sequence. The tool holder is connected, the drilling part 23 is located at the front end of the milling part 22, the milling part 22 has a certain taper, the guide part 21 includes at least two long spiral chip flutes 3 extending from the drilling part 23 to the tool handle 1, and the cutter body 2 The part between two adjacent long spiral chip flutes 3 constitutes a blade 7, and the blade 7 is provided with a cylindrical guide land 4 (that is, the blade 7) A cylindrical guide land 4) is set on the edge of the side that first enters into the rotation, and the milling part 22 intersects with the side of the long spiral chip flute 3 fac...

Embodiment 2

[0038] Such as Figure 4 and 5 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, there are two long helical chip removal flutes 3 and two short helical chip removal flutes 8, that is, each blade 7 Set 1 above.

[0039] This embodiment is suitable for a twist drill with a small tool diameter and a small width of the blade 7 . The drilling portion 23 includes two main drilling edges 231 and a chisel edge 232 . In the present embodiment, each design parameter is respectively α=10°, β 1 = 33°, β 0 = 30°, d=10mm, d min = 0.76d, L=6.8mm, L1=6.8mm, L2=4.6mm.

Embodiment 3

[0041] Such as Figure 6 and 7 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that in this embodiment, the number of long helical chip removal flutes 3 is set to three, and the number of short helical chip removal flutes 8 is set to three, that is, each blade 7 Set 1 above.

[0042] This embodiment is suitable for a three-blade twist drill, and the drilling part 23 includes three main drilling edges 231 and three chisel edges 232, and the design parameters are: α = 10°, β 1 = 33°, β 0 = 35°, d=10mm, d min = 0.76d, L=6.8mm, L1=6.8mm, L2=4.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com