Transparent bottle light inspection system

A transparent and light inspection technology, applied in sorting and other directions, can solve the problems of missed or false detection, time-consuming and labor-intensive light inspection system, etc., achieve accurate results of light inspection, improve light inspection efficiency, and prevent interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

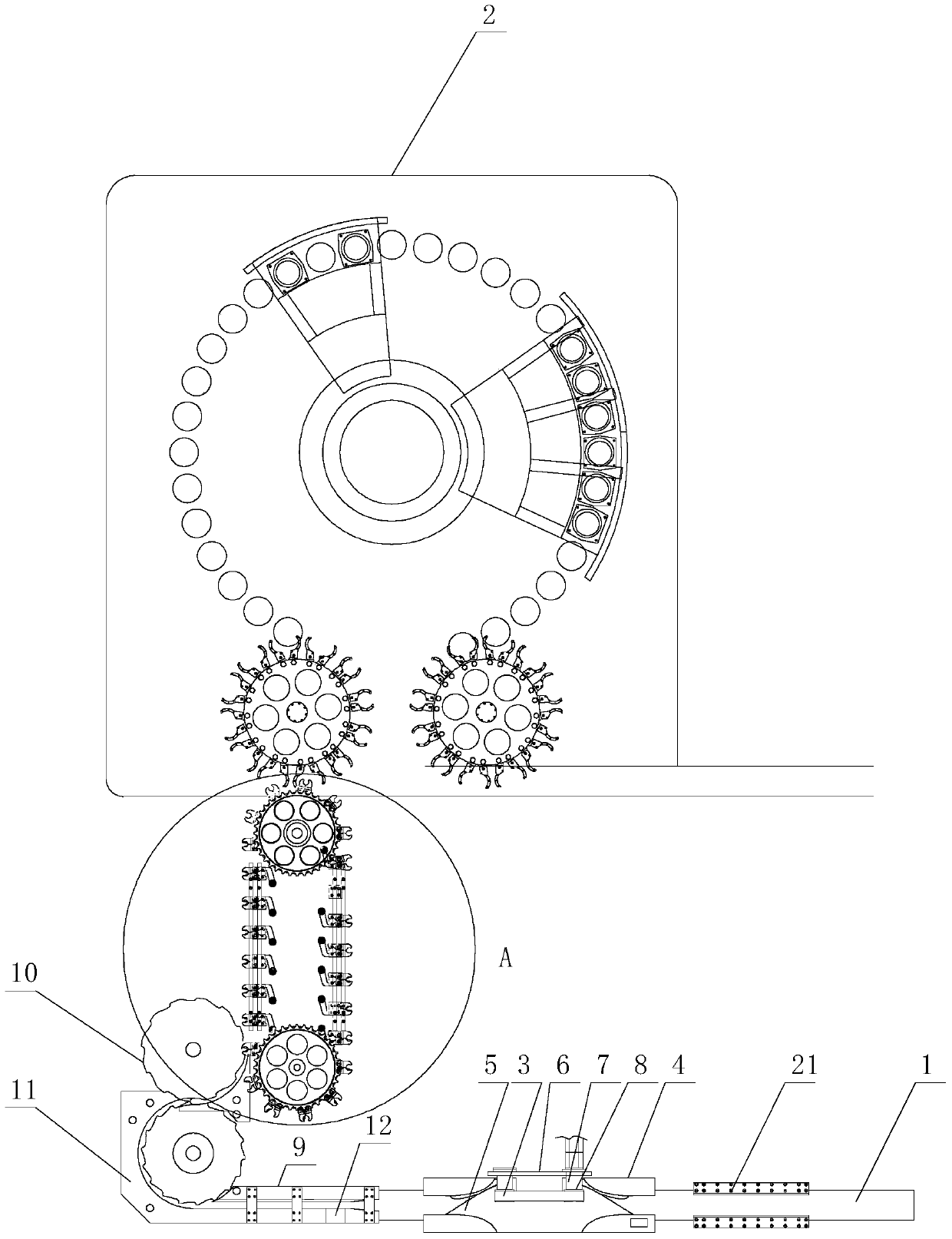

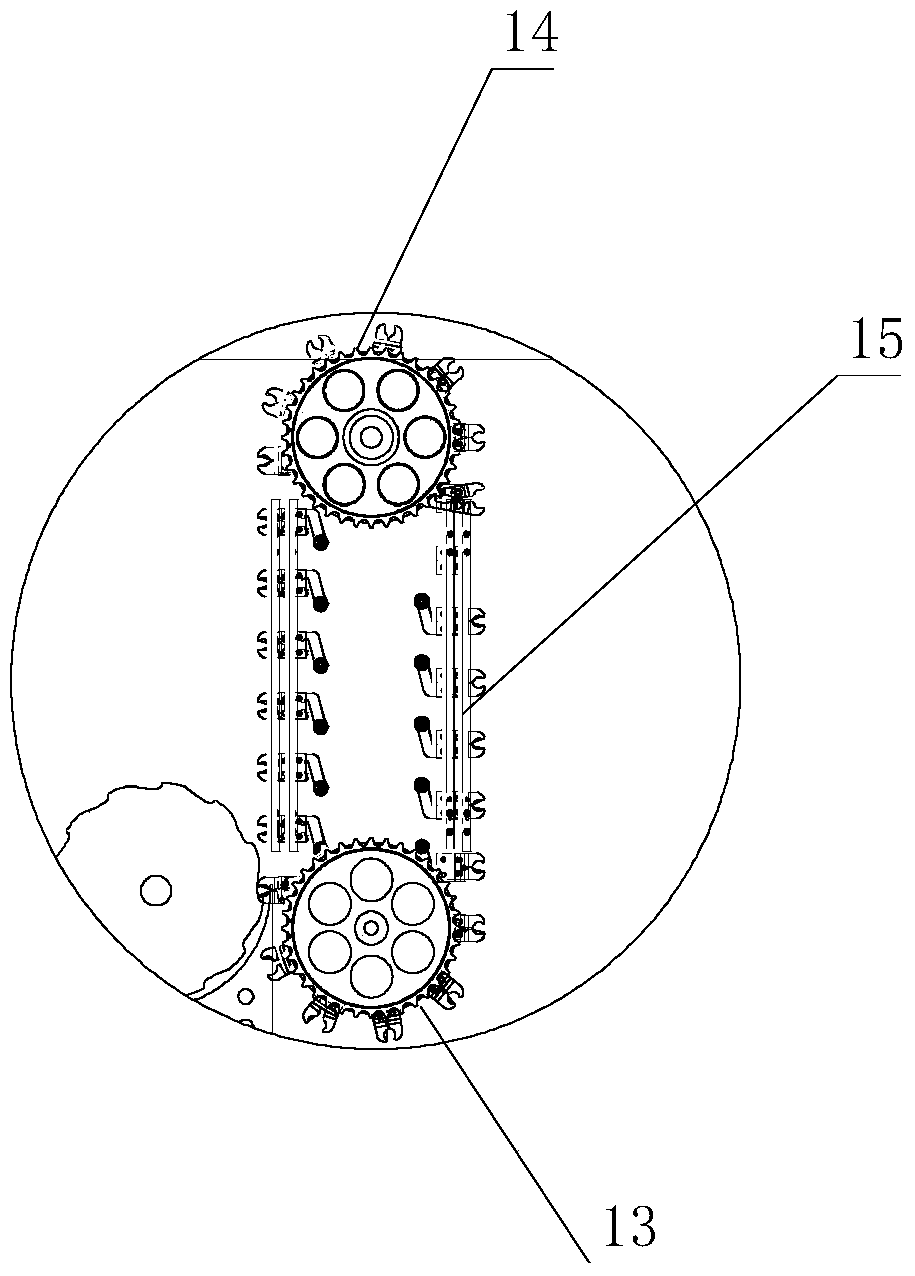

[0022] Such as Figure 1-4 As shown, the transparent bottle light inspection system includes a conveyor belt 1 and a light inspection machine 2; the conveyor belt is provided with a bottle defoaming mechanism, and the bottle outlet end of the conveyor belt 1 is provided with a dial bottle separating mechanism; It is used to transport the transparent bottle to the horizontal transport mechanism of the light inspection machine 2; the defoaming mechanism in the bottle includes a belt 3 and a base 4; the base 4 is fixed on the top of the conveyor belt 1, and there is a bottle inversion groove 5 on it, and the bottle inversion groove 5 is connected to the base The two ends of 4; the base 4 is provided with a support plate 6, the support plate 6 is provided with at least two rotating shafts 7, the rotating shaft 7 is connected with a runner 8 that drives the transparent bottle forward, and all the runners 8 are connected by a belt 3; transparent When the bottle arrives in the bottle...

Embodiment 2

[0026] Such as Figure 1-4 As shown, the difference between this embodiment and Embodiment 1 is that the transparent bottle light inspection system also includes a water removal mechanism outside the bottle; the water removal mechanism outside the bottle includes a plurality of air outlets 21 for drying the water mist on the surface of the bottle, and the air outlet 21 communicates with a wind source; the air outlet 21 is arranged on any one or more of the conveyor belt 1, the track 9, the arc guide plate 11, and the chain 15; the water removal mechanism outside the bottle selects its specific setting position according to actual needs.

Embodiment 3

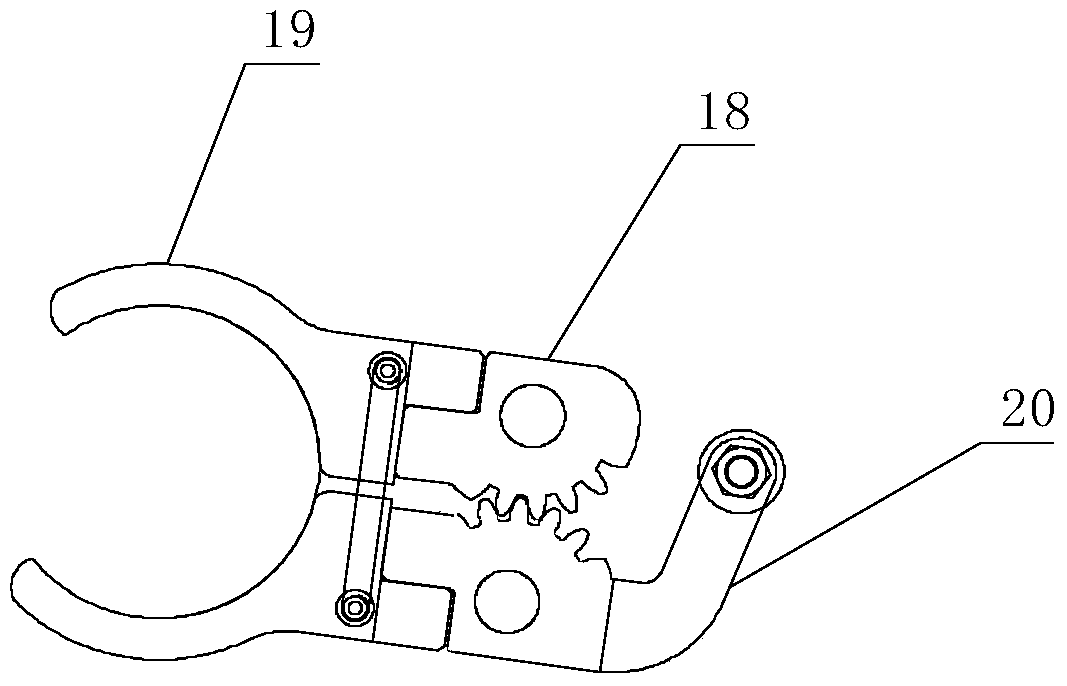

[0028] Such as Figure 1-4 As shown, the difference between the present embodiment and embodiment 1 and embodiment 2 is that at least one of the track 9 and the base 4 is provided with a vibrator 12; the vibrator 12 can be replaced by other devices with a vibrating effect; its quantity is as required Setting; the vibrator 12 on the track 9 makes the transparent bottle more stable on the track 9, and will not be stuck on the track 9 without deflection; the vibrator 12 on the base 4 makes the water in the transparent bottle move as much as possible, so that the water mist The bubbles are eliminated more thoroughly; the contact surfaces of the two connecting blocks 18 are respectively provided with gear teeth, and the gear teeth on the two connecting blocks 18 are engaged; a connecting plate is connected between the two connecting blocks 18, and the connecting plate and the connecting block 18 Rotational connection; the contact surfaces of the two connection blocks 18 can also be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com