Preparation method of metastable phase bismuth oxide and application thereof in photocatalytic degradation of organic pollutants

A bismuth oxide, metastable phase technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. The effect of high specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 (control experiment group)

[0040] 1. Weigh 113.04mg of ammonium bismuth citrate and 9mg of urea into 25ml of water, stir well at room temperature until completely dissolved into a white solution;

[0041] 2. Weigh 72.89mg of cetyltrimethylammonium bromide (CTAB) and add it to the above solution;

[0042] 3. Adjust the pH to 7, then stir for 30 minutes, transfer to a polytetrafluoroethylene liner, keep it in a stainless steel reactor at 180°C for 18 hours, and cool it down to room temperature naturally after the reaction;

[0043] 4. Collect the above reaction products, centrifuge them three times with water and alcohol at a speed of 13,000 rpm, dry them at 60°C, label sample 1, and save them for subsequent testing.

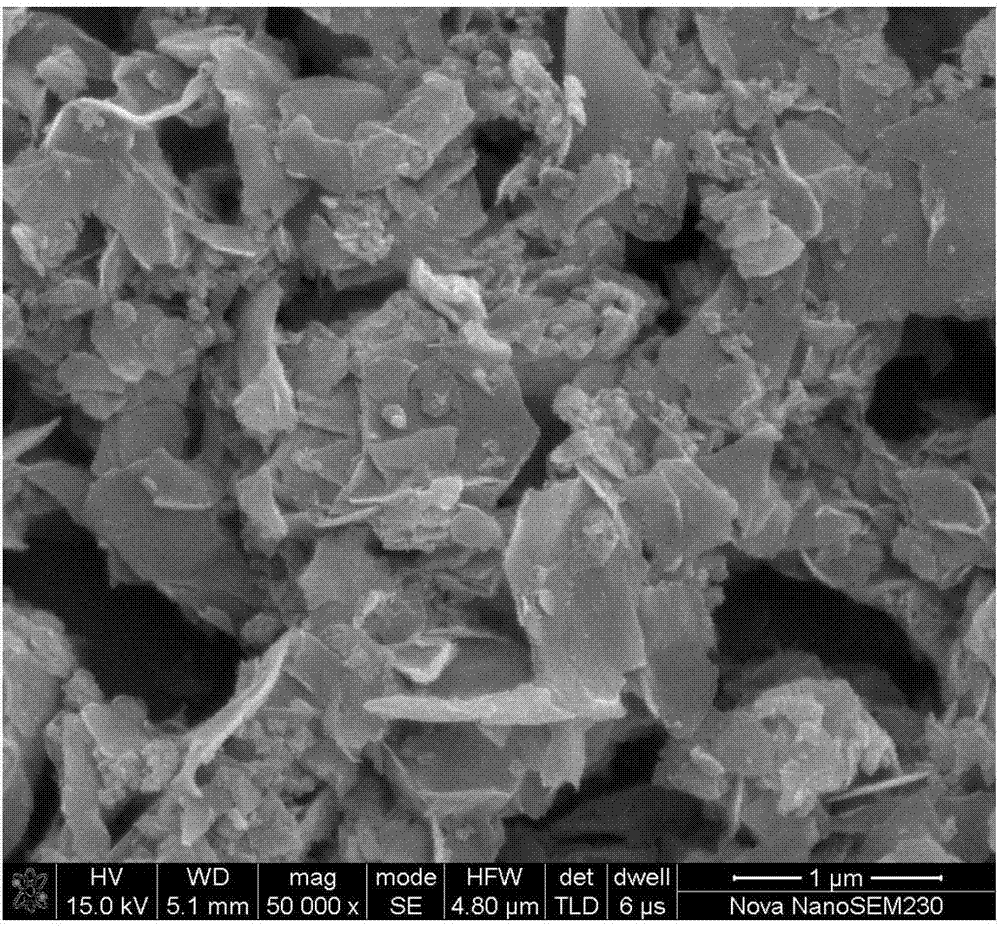

[0044] The final product was identified as bismuth oxycarbonate by X-ray diffraction, but due to the low content of urea, the morphology of bismuth oxycarbonate was shown as nano flakes and did not self-assemble into microflowers. (See Figu...

Embodiment 2

[0046] 1. Weigh 113.04mg of ammonium bismuth citrate and 15mg of urea into 25ml of water, stir well at room temperature until completely dissolved into a white solution;

[0047] 2. Weigh 72.89mg of cetyltrimethylammonium bromide (CTAB) and add it to the above solution;

[0048] 3. Adjust the pH to 7, then stir for 30 minutes, transfer to a polytetrafluoroethylene liner, keep it in a stainless steel reactor at 180°C for 18 hours, and cool it down to room temperature naturally after the reaction;

[0049] 4. Collect the above reaction products, centrifuge them three times with water and alcohol at a speed of 13,000 rpm, dry them at 60°C, label sample 2, and save them for subsequent testing.

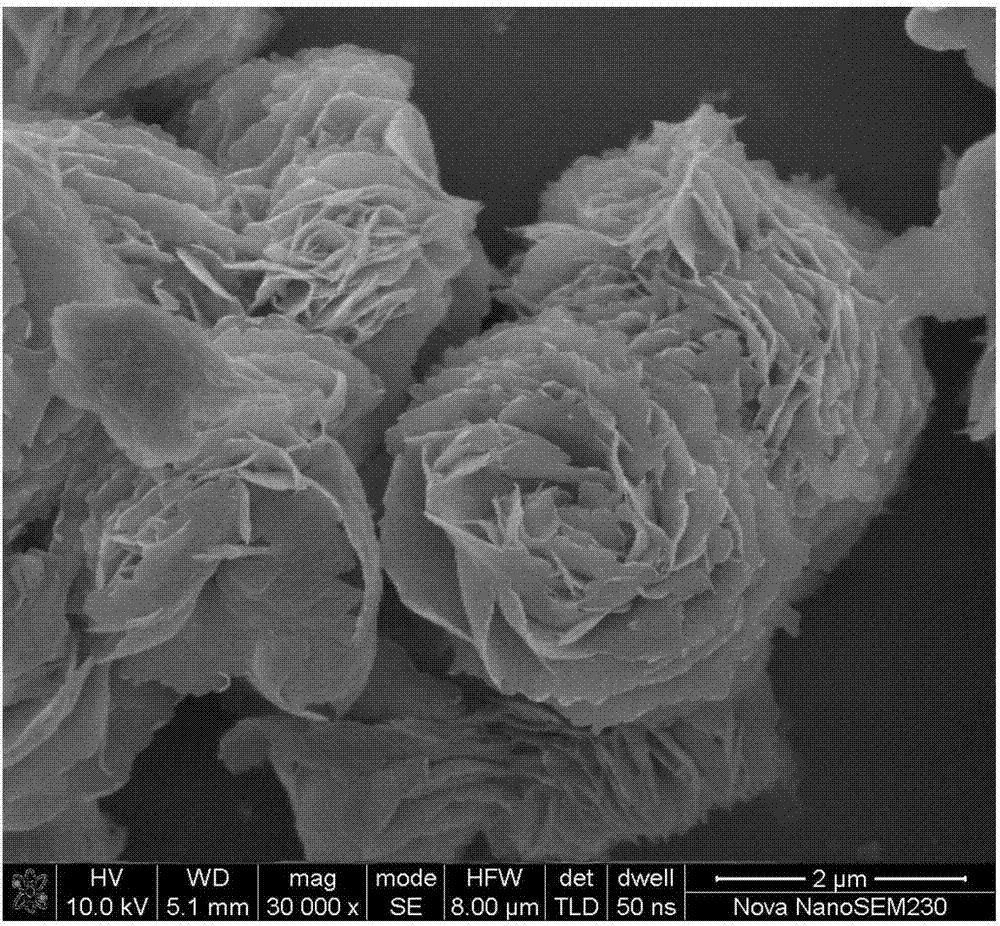

[0050] The visible light degradation performance test of the prepared bismuth oxycarbonate microflowers is as follows: add 10 mg of sample and 15 mL of rhodamine B solution (10 mg / L) to the reactor, stir in dark field for 60 min to reach adsorption equilibrium, and then irradiate with a vi...

Embodiment 3

[0052] Embodiment 3 (control experiment group)

[0053] The preparation method of bismuth oxycarbonate micron flower of the present invention, comprises the following steps:

[0054] 1. Weigh 113.04mg of ammonium bismuth citrate and 45mg of urea into 25ml of water, stir well at room temperature until completely dissolved into a white solution;

[0055] 2. Weigh 72.89mg of cetyltrimethylammonium bromide (CTAB) and add it to the above solution;

[0056] 3. Adjust the pH to 7, then stir for 30 minutes, transfer to a polytetrafluoroethylene liner, keep it in a stainless steel reactor at 180°C for 18 hours, and cool it down to room temperature naturally after the reaction;

[0057] 4. Collect the above reaction products, centrifuge them three times with water and alcohol at a speed of 13,000 rpm, dry them at 60°C, label sample 3, and save them for subsequent testing.

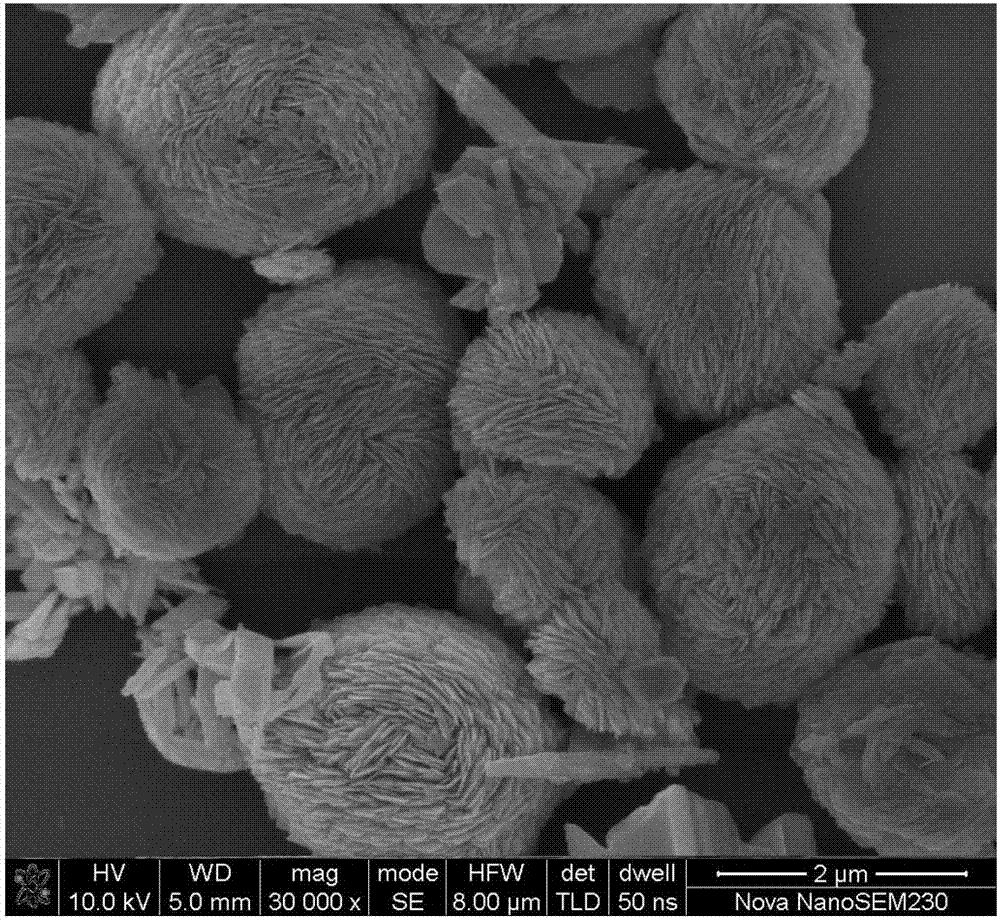

[0058] X-ray diffraction identified the final product as bismuth oxycarbonate, and its morphology also showed th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com