Microscopic observation method and device for rheological property of magnetorheological fluid

A magnetorheological fluid, microscopic technology, applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve problems such as constraints, inability to achieve effective observation and research, and achieve the effect of low cost, easy acquisition, and convenient laboratory application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

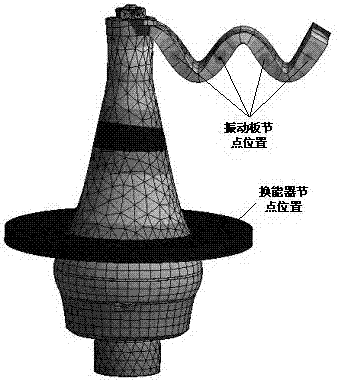

[0030] A device for observing microscopic dynamic changes of magnetorheological fluid under the action of optical microscope and ultrasonic near-field, with stepless adjustable magnetic field, such as figure 1 , image 3 and Figure 4 As shown, the microscopic observation device for the rheological properties of magnetorheological fluid under the action of ultrasonic near-field and steplessly adjustable magnetic field includes an ultrasonic near-field generating device based on the horn-type ultrasonic transducer 4, using the horn will consist of sandwich transducers based on piezoceramic d 33 The axial longitudinal vibration amplified by the inverse piezoelectric effect excites the bending vibration of the vibrating plate 5, and its vibration mode simulation diagram is shown in figure 2 , and arrange the vibrating plate 5 on one side of the 2 mm wide magnetorheological fluid cavity 9, so as to apply a standing wave ultrasonic near field to the magnetorheological fluid. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com