Transport embedding equipment used for underground pipeline embedding

A technology for underground pipelines and equipment, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc., and can solve problems such as time-consuming and laborious, inaccurate burial, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

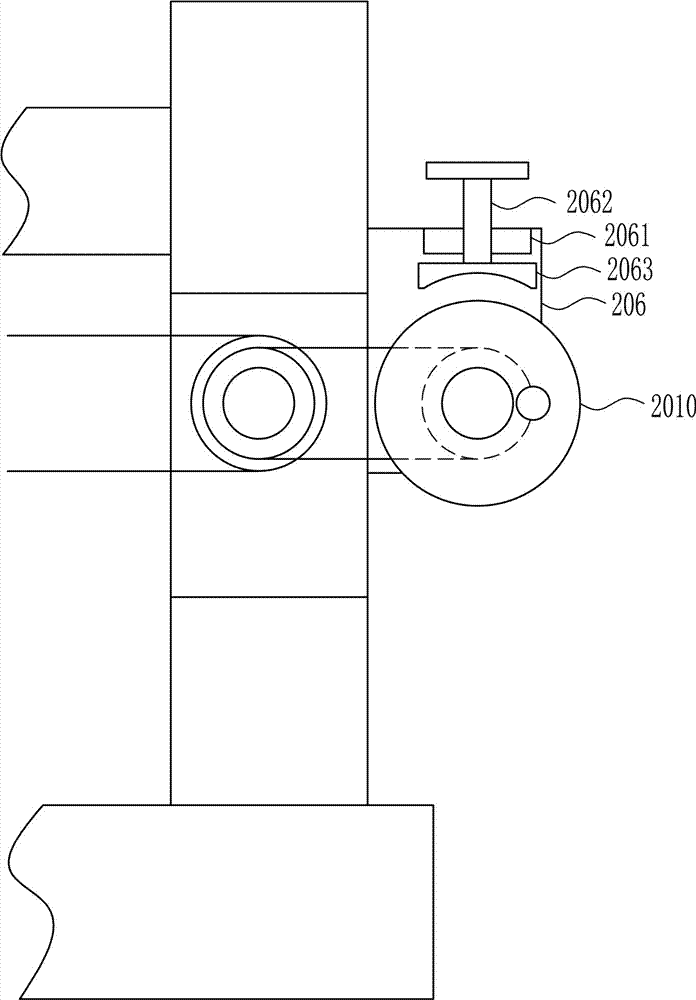

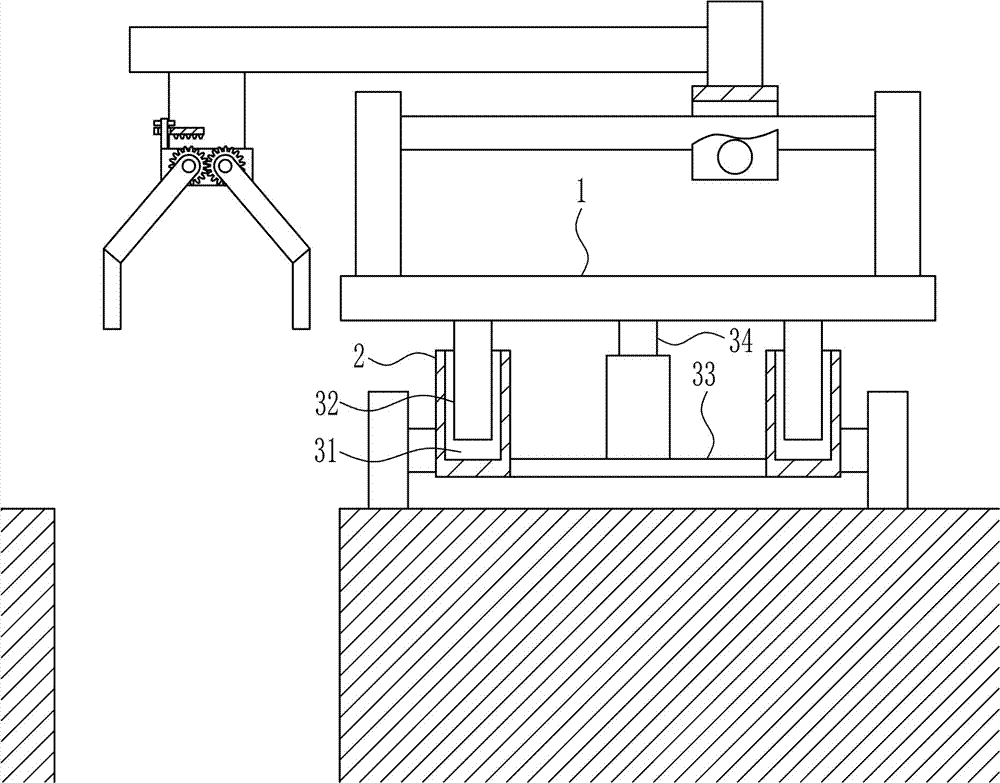

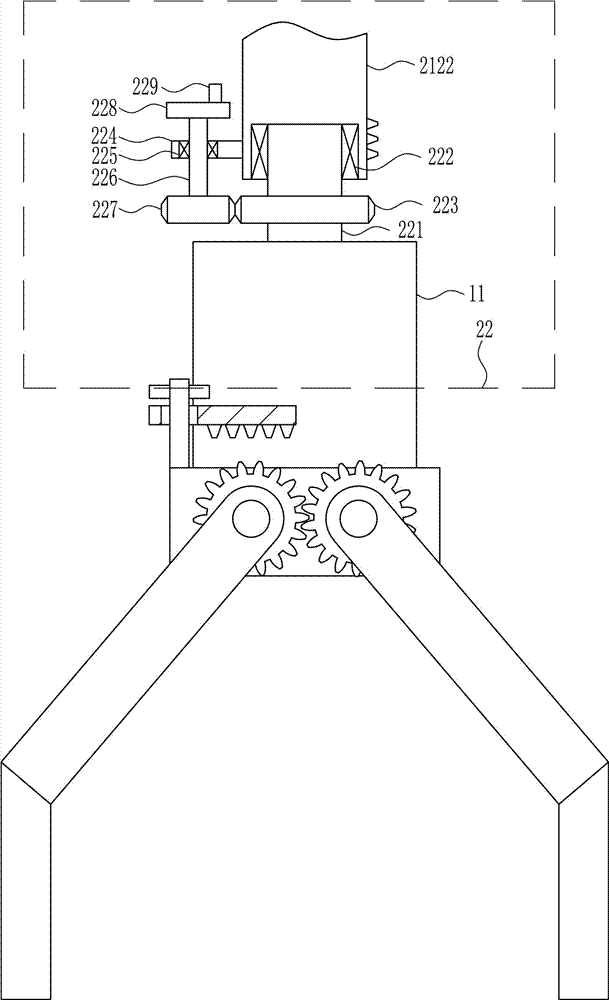

[0038] A kind of transport embedding equipment for underground pipeline embedding, such as Figure 1-8 As shown, it includes a mounting plate 1, a support seat 2, a first rotating shaft 3, a tire 4, a first fixing plate 5, a first guide rail 6, a first guide sleeve 7, a handle 8, a fixing block 9, a support rod 10, a first A connection block 11, a mounting block 12, a second rotating shaft 13, a splint 14, a first gear 15, a first screw rod 16, a pressure plate 17, a first rack 18 and a first nut 19, the left and right sides of the lower side of the mounting plate 1 pass through The support base 2 is installed by welding, the first rotating shaft 3 is connected to the lower outside of the supporting base 2, and the tire 4 is connected to the outer side of the first rotating shaft 3 in a rotatable manner. The first guide rail 6 is installed by welding between the plate 5 and the upper inner side of the first fixed plate 5, and the first guide sleeve 7 is slidably connected to t...

Embodiment 2

[0040] A kind of transport embedding equipment for underground pipeline embedding, such as Figure 1-8As shown, it includes a mounting plate 1, a support seat 2, a first rotating shaft 3, a tire 4, a first fixing plate 5, a first guide rail 6, a first guide sleeve 7, a handle 8, a fixing block 9, a support rod 10, a first A connection block 11, a mounting block 12, a second rotating shaft 13, a splint 14, a first gear 15, a first screw rod 16, a pressure plate 17, a first rack 18 and a first nut 19, the left and right sides of the lower side of the mounting plate 1 pass through The support base 2 is installed by welding, the first rotating shaft 3 is connected to the lower outside of the supporting base 2, and the tire 4 is connected to the outer side of the first rotating shaft 3 in a rotatable manner. The first guide rail 6 is installed by welding between the plate 5 and the upper inner side of the first fixed plate 5, and the first guide sleeve 7 is slidably connected to th...

Embodiment 3

[0043] A kind of transport embedding equipment for underground pipeline embedding, such as Figure 1-8 As shown, it includes a mounting plate 1, a support seat 2, a first rotating shaft 3, a tire 4, a first fixing plate 5, a first guide rail 6, a first guide sleeve 7, a handle 8, a fixing block 9, a support rod 10, a first A connection block 11, a mounting block 12, a second rotating shaft 13, a splint 14, a first gear 15, a first screw rod 16, a pressure plate 17, a first rack 18 and a first nut 19, the left and right sides of the lower side of the mounting plate 1 pass through The support base 2 is installed by welding, the first rotating shaft 3 is connected to the lower outside of the supporting base 2, and the tire 4 is connected to the outer side of the first rotating shaft 3 in a rotatable manner. The first guide rail 6 is installed by welding between the plate 5 and the upper inner side of the first fixed plate 5, and the first guide sleeve 7 is slidably connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com