Preparation method of ceramic tile with energy storage and sound insulation functions and ceramic tile

A ceramic tile and function technology, applied in the field of ceramic tile and ceramic tile preparation, can solve the problems of high thermal conductivity, unfavorable thermal insulation and energy saving, poor sound insulation performance, etc., and achieves high strength, good indoor environment comfort effect, moisture-proof and waterproof performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

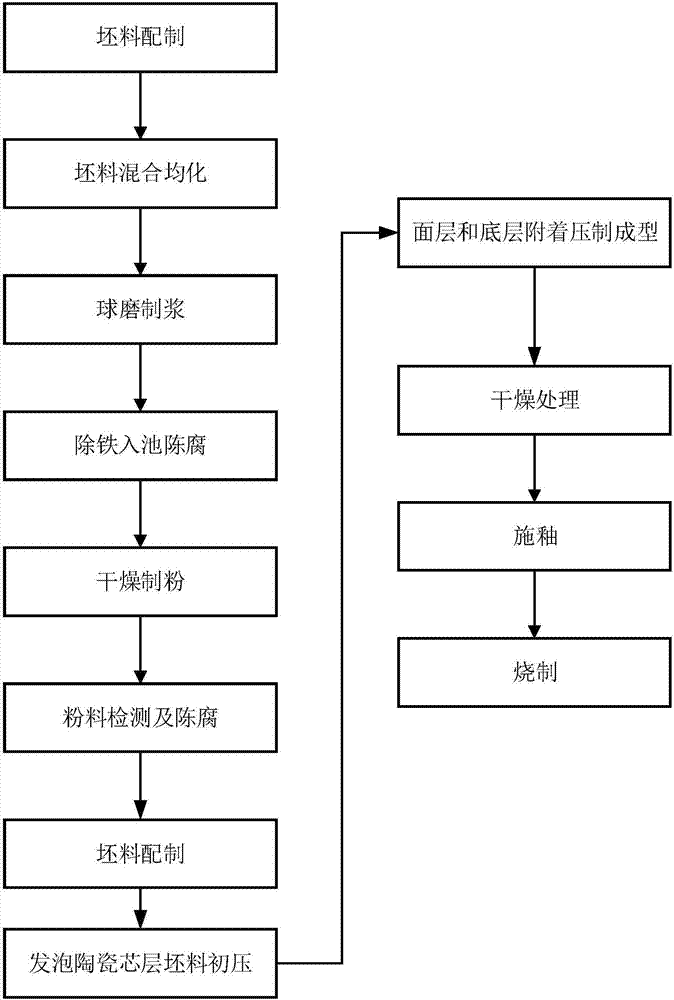

[0049] A method for preparing ceramic tiles with energy storage and sound insulation functions,

[0050] In the preparation, first check and accept the raw material of the billet, and then homogenize the raw material of the billet to remove the impurities in the plastic raw material,

[0051] Then proceed to the following steps:

[0052] Step 1, blank preparation: prepare the raw materials according to the formula;

[0053] Step 2, mixing and homogenizing the blank: mixing and homogenizing the above-mentioned raw materials for the blank;

[0054] Step 3, ball milling pulping: send the above mixed and homogenized billet into ball milling equipment, and the time of ball milling can be 12 hours.

[0055] Step 4, remove iron and put it into the pool for stale: sieve the billet obtained after being sent to the ball mill equipment, and then perform iron removal treatment, mix the billet with water to obtain mud, and put the mud into the slurry pool to stale;

[0056] Step 5. Dryi...

Embodiment 1

[0085] A method for preparing ceramic tiles with energy storage and sound insulation functions, comprising the following steps:

[0086] 1. Sampling, testing and acceptance of incoming raw materials;

[0087] 2. Raw material pretreatment: remove impurities from plastic raw materials such as clay, feldspar, and quartz sand;

[0088] 3. Billet preparation: feldspar (Jinlongshi, etc.) 40%, sand: 35%; clay (white mud, black mud, etc.): 25%;

[0089] 4. Billet mixing and homogenization: According to the confirmed billet formula, the billet is mixed and homogenized and then prepared for use;

[0090] 5. Ball mill pulping: send the mixed and homogenized billet into the ball mill equipment, and ball mill for 12 hours;

[0091] 6. Remove iron and put it into the pool for staleness: pass the ball milled billet through a sieve with ten thousand holes (250 meshes), and sieve the remaining 0.5%, and after iron removal, mix with water to obtain mud with a moisture content of 50%, and put ...

Embodiment 2

[0104] A method for preparing ceramic tiles with energy storage and sound insulation functions, comprising the following steps:

[0105] 1. Sampling, testing and acceptance of incoming raw materials;

[0106] 2. Raw material pretreatment: remove impurities from plastic raw materials such as clay, feldspar, and quartz sand;

[0107] 3. Billet preparation: 20% of black mud, 18% of flake soil; 15% of medium and high temperature sand; 32% of high temperature sand; 9% of limestone; 5% of plain clay, etc.;

[0108] 4. Billet mixing and homogenization: According to the confirmed billet formula, the billet is mixed and homogenized and then prepared for use;

[0109] 5. Ball mill pulping: send the mixed and homogenized billet into the ball mill equipment, and ball mill for 12 hours;

[0110] 6. Remove iron and put it into the pool for staleness: pass the ball milled billet through a sieve with ten thousand holes (250 meshes), and sieve the remaining 0.5%, and after iron removal, mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com