High-precision double-head labelling machine

A labeling machine, high-precision technology, applied in the direction of labeling machines, labels, packaging, etc., can solve the problems of difficult to adapt to the labeling method, many labels attached, low attachment accuracy, etc., to ensure normal adsorption effect, improve Stability, the effect of improving labeling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention proposes a high-precision double-head labeling machine.

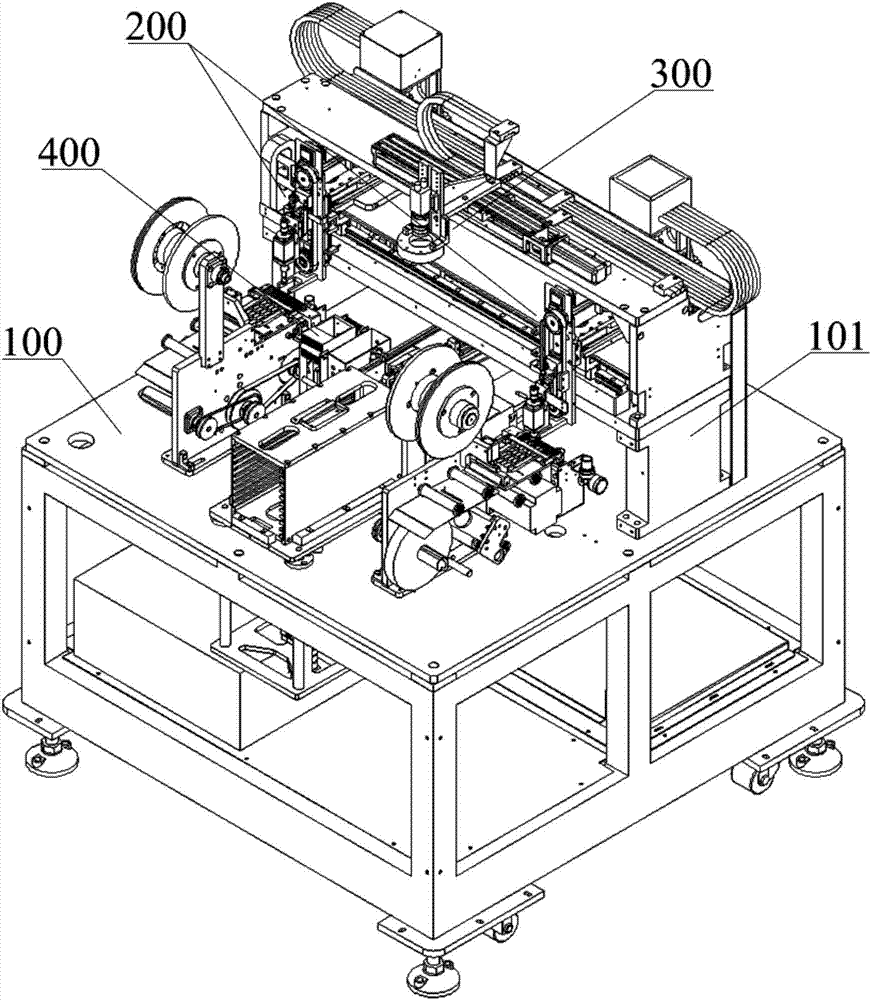

[0031] refer to figure 1 , figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention.

[0032] like figure 1 As shown, in the embodiment of the present invention, the high-precision double-head labeling machine includes: a workbench 100 , two labeling head assemblies 200 , a first visual positioning assembly 300 , and two second visual positioning assemblies 400 . Wherein, the product to be pasted is arranged on the workbench 100, and the labels to be pasted are respectively arranged on both sides of the product to be pasted.

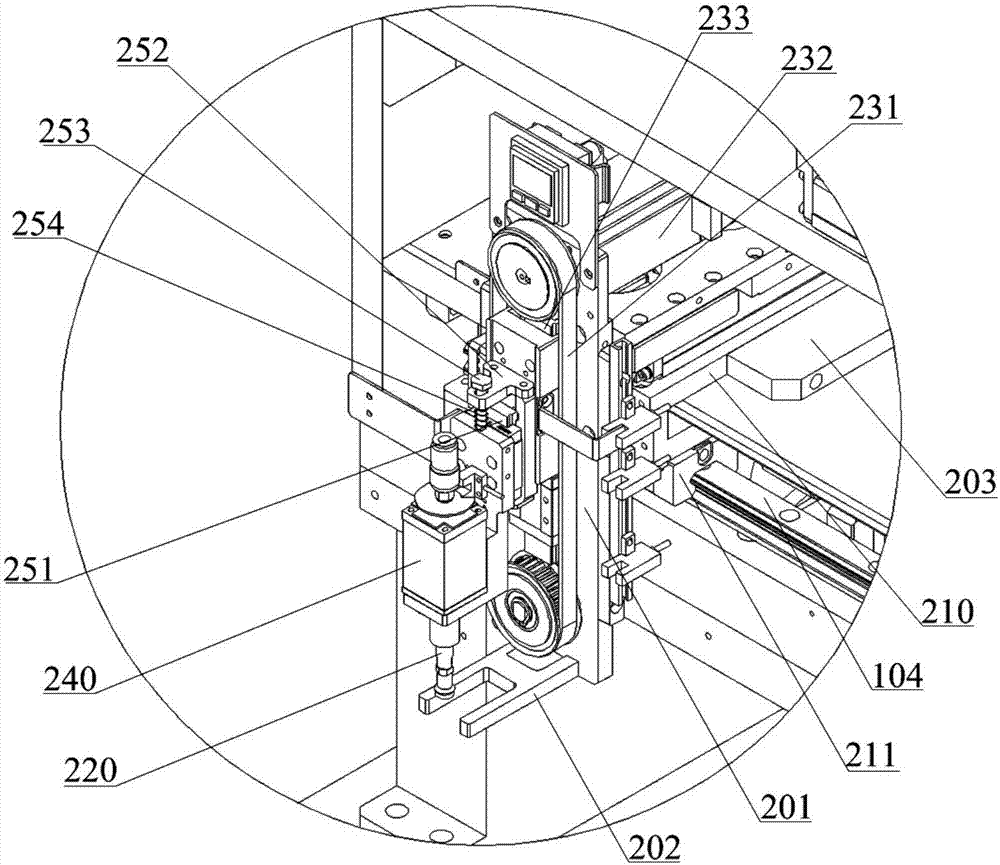

[0033] like figure 2 As shown, a support frame 101 is provided on the workbench 100, and a first flat plate 102 and a second flat plate 103 are arranged on the support frame 101 in parallel up and down, and the two sides of the second flat plate 103 are respectively provided with second flat plates 103. The two labeling head a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com