Manufacturing method for triple gear

A manufacturing method and triple gear technology, which is applied in the field of gear manufacturing, can solve the problems that the precision and roughness of the teeth are difficult to achieve the ideal state, the roughness of the tooth surface of the bevel teeth is poor, and the energy consumption is large, so as to save energy and materials, The effect of high product precision and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

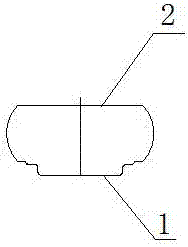

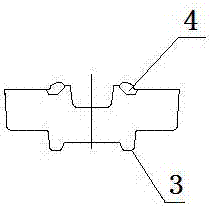

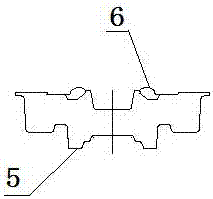

[0031] Refer to the above attached figure 1 A method for manufacturing a triple gear (the triple gear of the 425 bridge is an example), which is characterized in that the manufacturing method includes a blanking process, a heating process, an upsetting process, a pre-forging process, a final forging process, an anti-oxidation process, spraying Pill process, lubrication process, shaping process and inspection process; the specific manufacturing method is as follows:

[0032] A, the described blanking process: select the metal bar that meets the requirements, and draw the three-dimensional figure of the triple gear by CAD, obtain the volume of the triple gear by the CAD software, then multiply the weight of the triple gear by the metal bar density, The weight tolerance of the triple gear is obtained as ±0.5%; then the length of the metal bar is calculated based on the weight and density of the triple gear and the diameter of the metal bar; and then the material is cut according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com