Novel flour grinding equipment

A surface grinding and equipment technology, applied in the field of new surface grinding equipment, can solve problems such as low grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

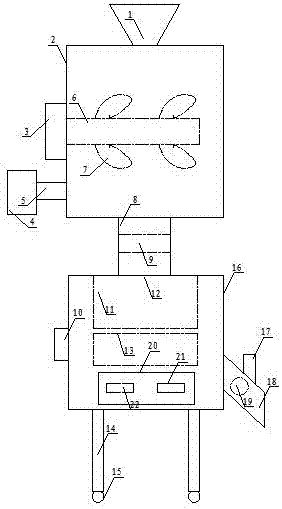

[0018] Such as figure 1 The new type of noodle grinding equipment includes a feed port 1, a crushing chamber 2, a first motor 3, a blower 4, a blowing duct 5, a rotating shaft 6, a blade 7, a channel 8, a screen 9, and a second motor 10 , upper grinding plate 11, inlet 12, lower grinding plate 13, bracket 14, universal pulley 15, grinding chamber 16, vacuum cleaner 17, discharge port 18, flow controller 19, main control panel 20, display screen 21, main The controller 22 is provided with a feed inlet 1 at the upper end of the crushing chamber 2, a first motor 3 is provided at one side of the crushing chamber 2, a rotating shaft 6 is provided in the crushing chamber 2, a blade 7 is arranged on the rotating shaft 6, and the first motor 3 is connected with the rotating shaft 6 , the crushing chamber 2 is connected to the milling chamber 16 through the passage 8, and an upper milling plate 11 and a lower milling plate 13 are arranged in the milling chamber 16, and the inlet 12 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com