Solid fermenting process

A solid-state fermentation and process technology, applied in the application, animal feed, animal feed and other directions, can solve the problem of no major development, and achieve the effects of suitable fermentation conditions, uniform heat distribution, and good heating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

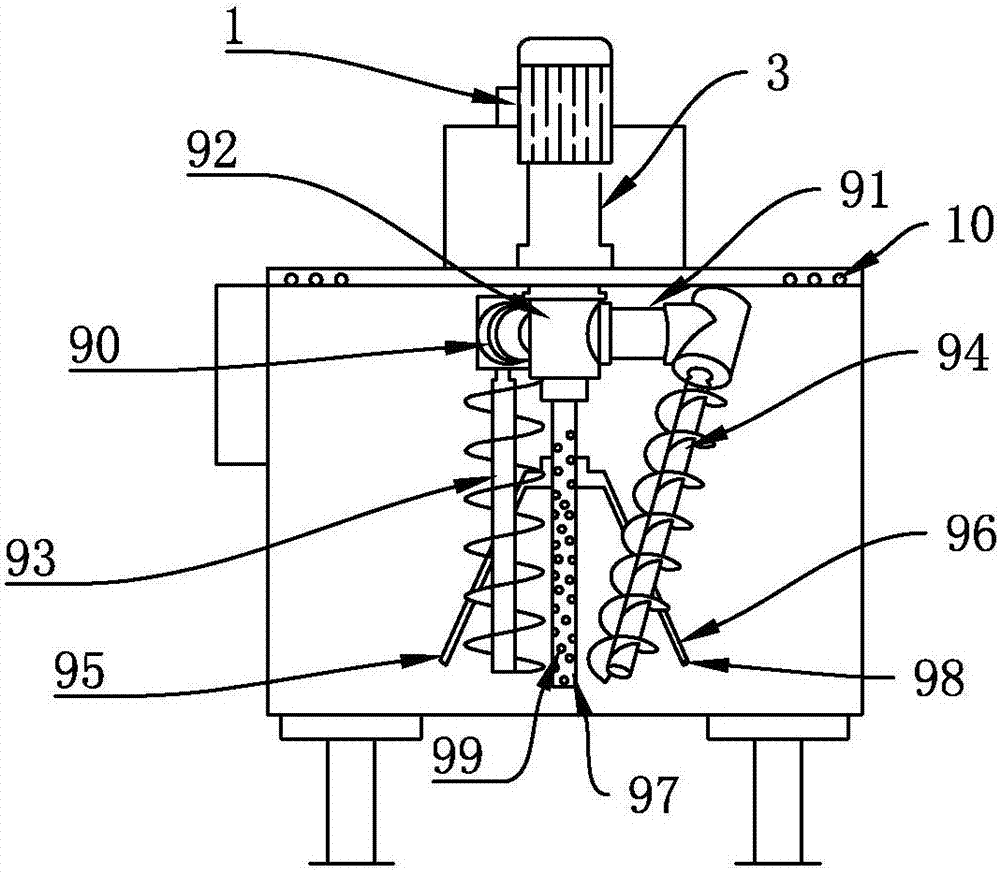

[0037] Such as figure 1 and figure 2As shown, a device used in a solid-state fermentation process includes a sealed housing 4 provided with an interlayer, and the top of the housing is provided with a motor 1, a reducer 3, an air supply device, a spraying device 10, and a solid material feed port 22 and the exhaust port, the inside of the housing 4 is provided with a stirring device; the bottom of the housing 4 is provided with a solid material discharge port 23, and the solid material feed port 22 and the solid material discharge port 23 are blocked by a pneumatic strut, which includes a cover Plate 20, support rod 21, one end of the cover plate 20 is hinged to the edge of the feed port 22, the middle part is hinged to one end of the support rod 21, and the other end of the support rod 21 is connected to the reducer 3; the exhaust port is connected to the exhaust fan through a pipeline, and the exhaust fan is connected to to the controller 6; a hot air inlet 8 is also provi...

Embodiment 2

[0053] Embodiment two: Solid state fermentation one:

[0054] 1. Mix vermicelli residue with bran, corn flour and glucose mixture (mass ratio is 20:5:1) respectively according to the ratio of mass ratio 1:0.43, and put it into the fermentation device. 70% of the volume of the equipment, fully stir and mix;

[0055] 2. Adjust the water content of the material to 40%, and stir well;

[0056] 3. Heat the material to 70°C, mature at high temperature for 20 minutes, and then turn on the water cooling cycle cooling system to cool down to 45°C.

[0057] 4. Enter the Enterococcus faecalis: Saccharomyces cerevisiae: Bacillus subtilis mixture with a mass ratio of 1:2:1 according to 0.2% of the total mass of the material, and fully stir and mix;

[0058] 5. Adjust the stirring time to 15 minutes / 3 hours, keep aeration (9 cubic meters per minute) while stirring, the speed is 1 revolution per minute, and the heating temperature is controlled to 30°C;

[0059] 6. After 12 hours of ferm...

Embodiment 3

[0060] Embodiment three: Solid state fermentation two:

[0061] 1, get bagasse and the mixture (mass ratio is 20:5:1) of bran, cornflour and glucose to mix respectively by the ratio of mass ratio 1:0.8, drop into in the described fermenting device, described mixed material volume is not More than 70% of the volume of the fermentation equipment, fully stir and mix;

[0062] 2. Adjust the water content of the material to 50%, and stir well;

[0063] 3. Heat the material to 75°C, cure at high temperature for 40 minutes, and then turn on the air cooling system to cool down to 37°C.

[0064] 4. Enter the Enterococcus faecalis: Saccharomyces cerevisiae: Bacillus subtilis mixture with a mass ratio of 1:2:1 according to 0.15% of the total mass of the material, and fully stir and mix;

[0065] 5. Adjust the stirring time to 22 minutes / 3 hours, keep ventilation (9 cubic meters per minute) during stirring, the speed is 1.5 revolutions per minute, and the heating temperature is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com