Integrated ice cream puffing pump with inlet air regulation and ice cream maker

A technology of air intake adjustment and ice cream, applied in frozen sweets, food science, applications, etc., can solve the problems of inconvenient disassembly and washing, high processing precision and assembly requirements, complex structure, etc., to ensure hygiene and safety, easy to disassemble and clean, Easy to disassemble and wash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

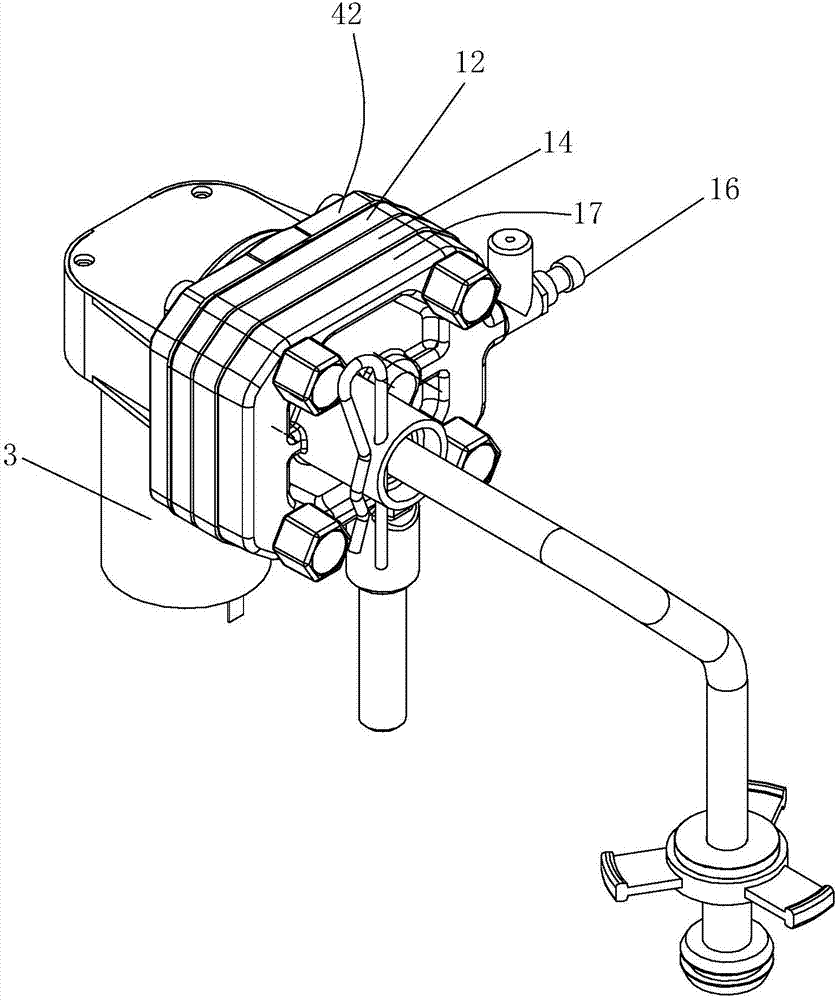

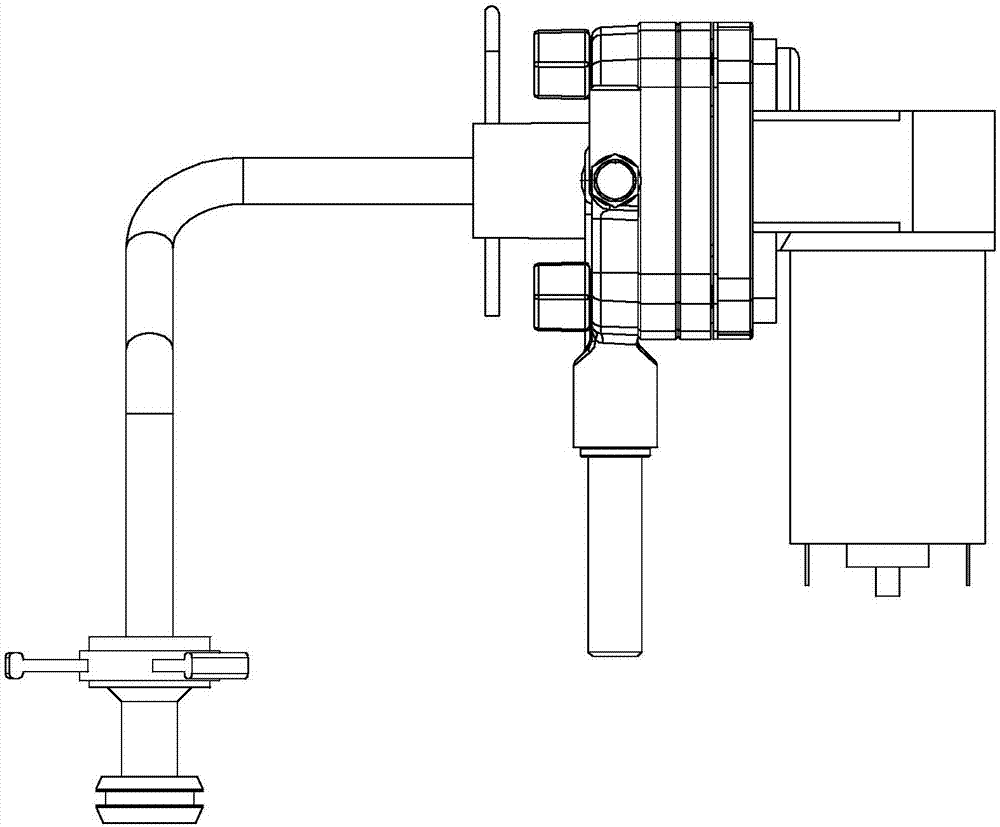

[0038] Such as Figure 7 The ice cream machine shown includes a fuselage 24, and the upper part of the fuselage 24 has two material cylinders 25, and an expansion pump is installed on the side wall of each material cylinder 25. The material cylinder 25 is easy to disassemble and clean. When disassembling the material cylinder 25, the puffing pump is also disassembled from the ice cream machine, which facilitates the cleaning of the puffing pump.

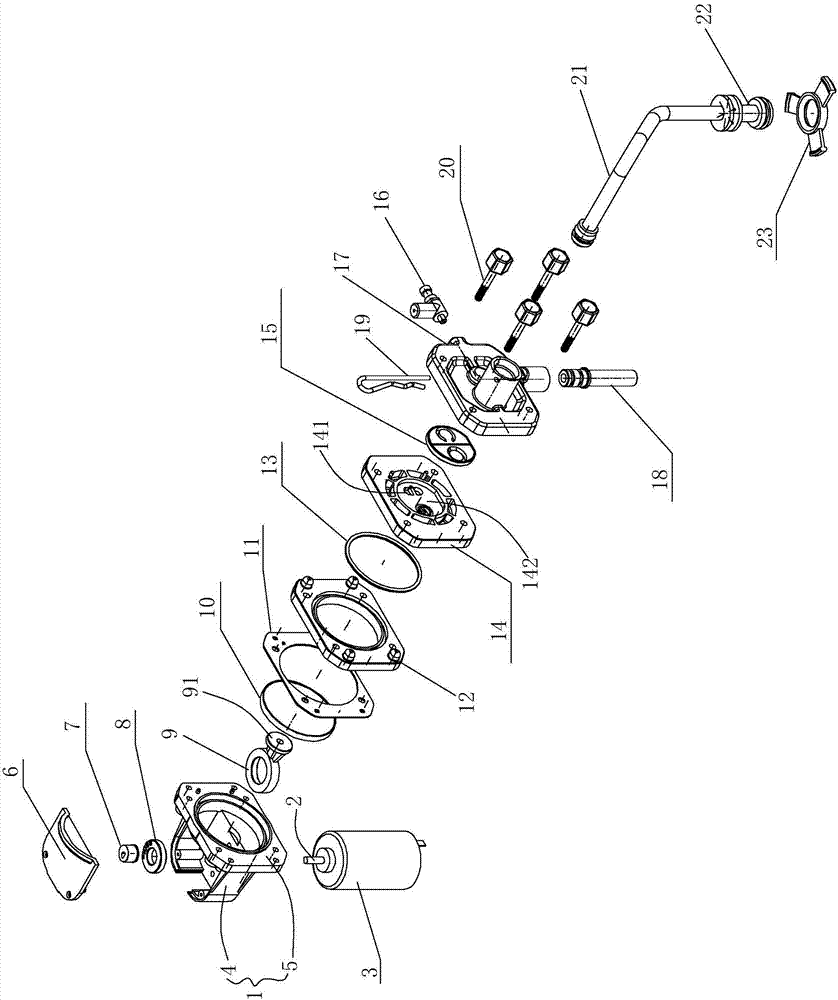

[0039] Such as Figure 1 to Figure 7 The shown integrated ice cream puffing pump with air intake adjustment includes a feed pump and a pump base 1, the feed pump has a feed pipe 18, a pump cavity and a discharge pipe 21, and the feed pipe 18 and the discharge pipe 21 are both It communicates with the pump cavity, and the material pump is installed on the pump base 1. The side of the material pump is equipped with an air intake regulating valve 16 connected with the pump cavity of the material pump. The air is mixed in the pump cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com