Rotary self-cleaning high-voltage electrostatic type oil fume purifier

A fume purifier, high-voltage electrostatic technology, applied in the direction of external electrostatic separator, electrode cleaning, electrostatic separation, etc., can solve the problem that the gap between the scraper and the adsorption plate is difficult to control, the oil cannot be effectively scraped off, and it is difficult to clean. To achieve the effect of prolonging the service life, cleaning clean and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

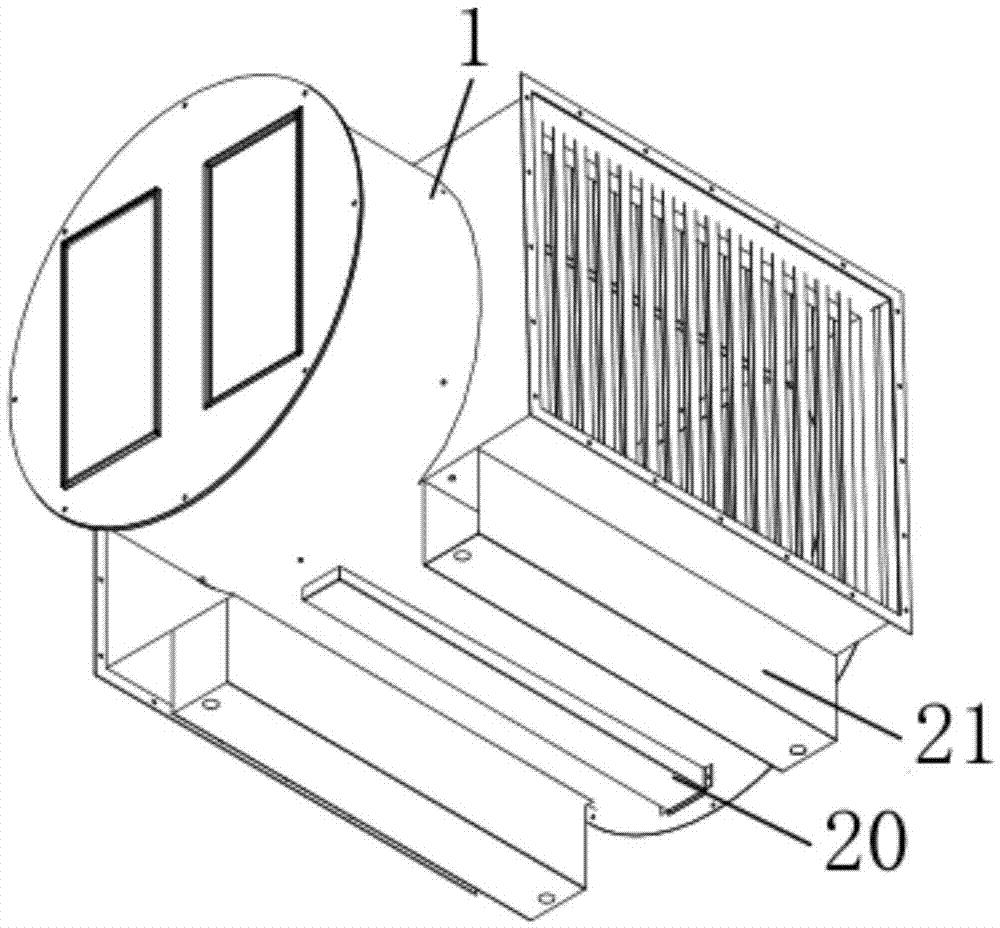

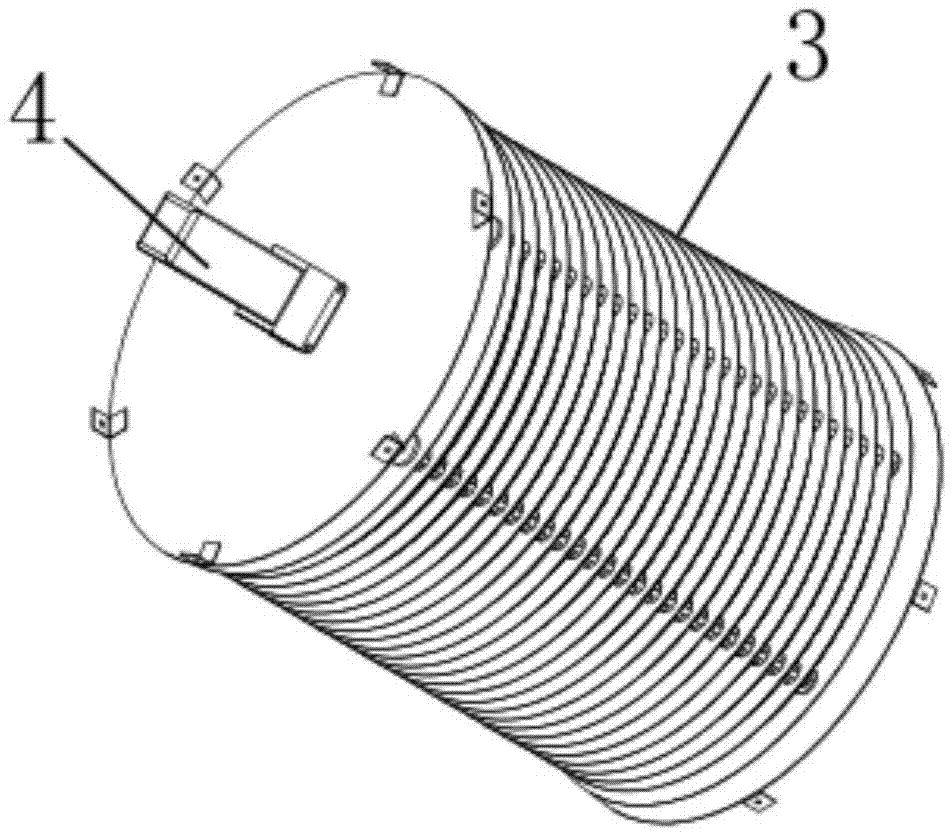

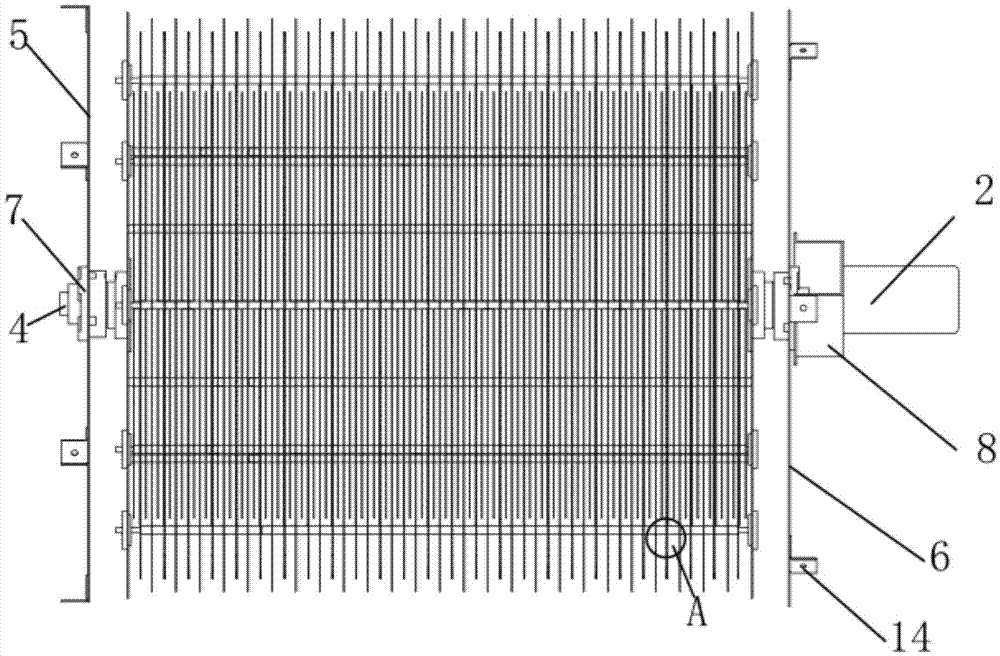

[0023] like Figure 1 ~ Figure 3 As shown, the present invention includes an outer box body 1 and a driving motor 2 arranged in the outer box body 1, and a high-voltage electrostatic field core 3 is arranged in the outer box body 1; rotating shafts 4 are arranged on both sides of the high-voltage electrostatic field core; The left side of the field core is provided with a left support plate 5, and the right side is provided with a right support plate 6; both the left support plate 5 and the right support plate 6 are connected to the high-voltage electrostatic field core 3 through a bearing 7;

[0024] The driving motor 2 is arranged on the right side of the high-voltage electrostatic field core 3, and is connected with the rotating shaft 4 through the motor fixing frame 8; the high-voltage electrostatic field core 3 is composed of a high-voltage electrostatic plate group; the outer box is provided with an air inlet 9 and an air outlet 10 ; The air inlet 9 is provided with a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com