Slip sheet of vane type compressor and vane type compressor

A compressor and rotary vane technology, applied in the field of compressors, can solve the problem of large bias force of the sliding vane, and achieve the effects of improving the service life, preventing excessive friction loss, and reducing frictional power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

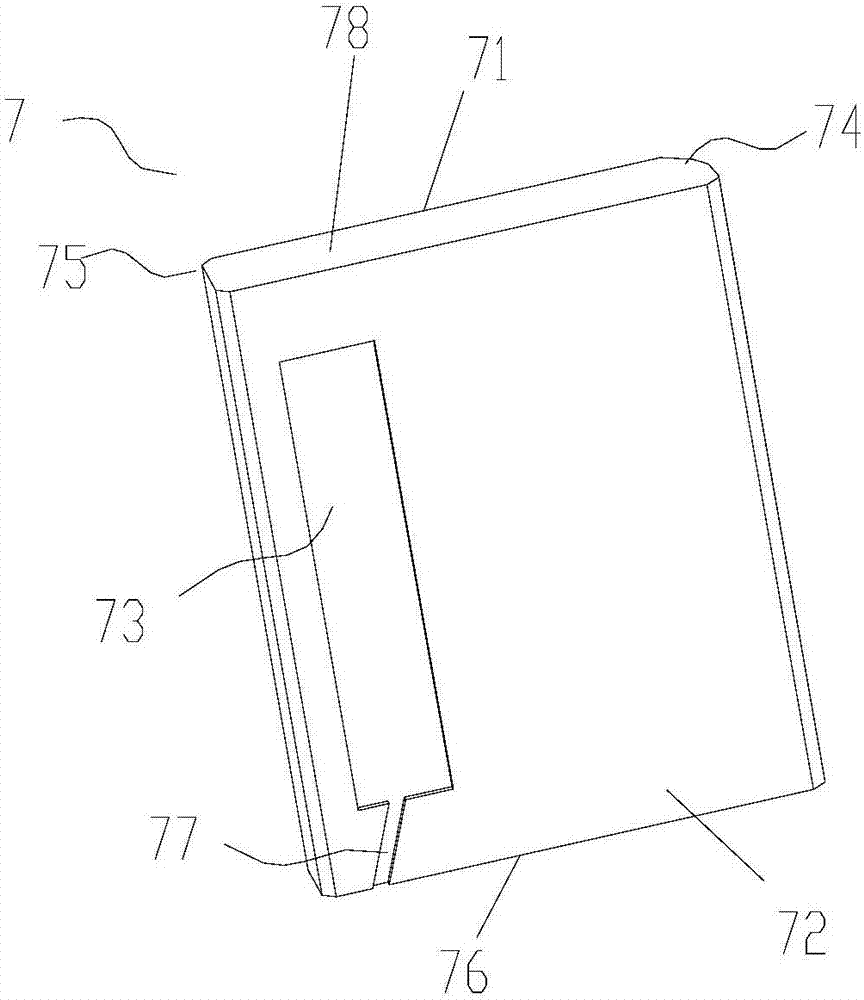

[0042] Such as figure 1 As shown, the present invention provides a sliding vane 7 of a rotary vane compressor, which includes: a first side 71 and a second side 72, wherein the first side 71 and the second side 72 are arranged opposite to each other, and at the A side oil groove 73 capable of accommodating high-pressure oil is provided on the second side 72, and the side oil groove 73 is opened from the second side 72 in a direction toward the first side 71, and does not pass through the first side. 71.

[0043]On the second side of the oppositely arranged first and second sides of the sliding plate, a side oil groove is opened toward the first side but does not pass through the first side, and the side oil groove contains high-pressure oil, which can pass through the The side oil tank is filled with high-pressure oil, so that the pressure vertical to the slide can be formed on the second side of the slide to balance or reduce the bias force generated by the front end of the ...

Embodiment 2

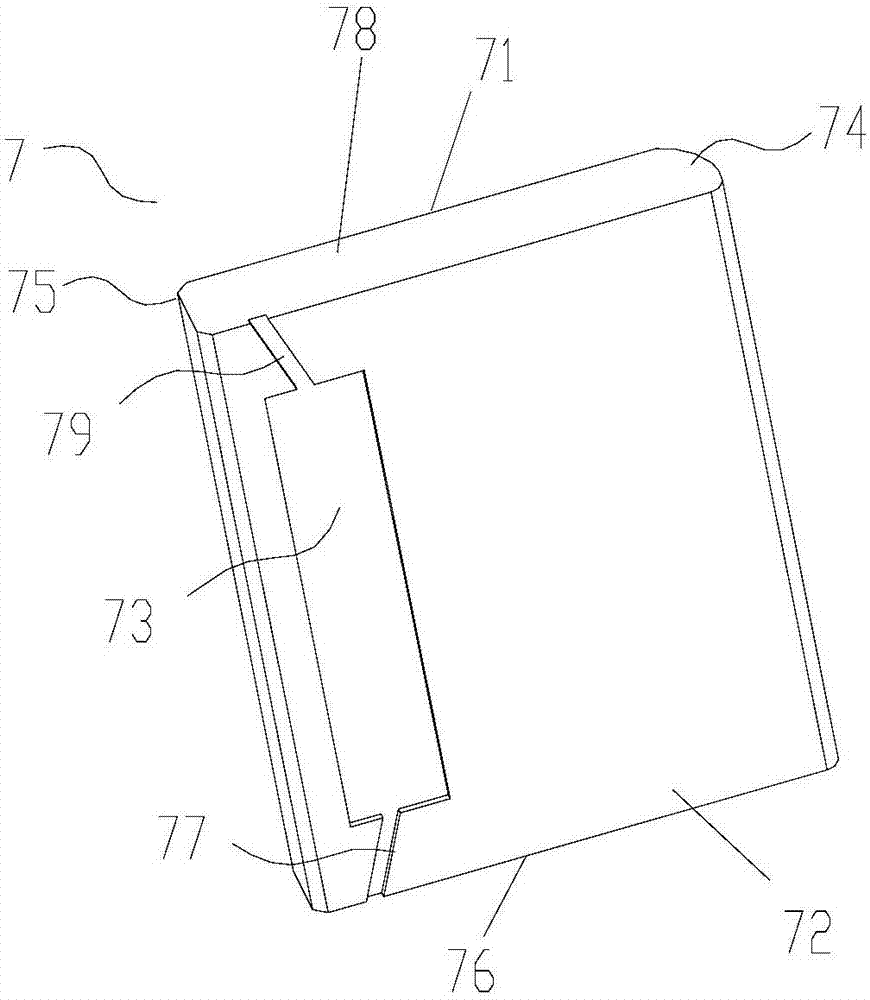

[0048] Such as figure 2 As shown, this embodiment is a further improvement made on the basis of Embodiment 1, which belongs to the means added on the basis of the technical solution of Embodiment 1. Preferably, an end is also provided on the second side 72 The second oil groove channel 79 communicates with the side oil groove 73 and extends to the upper end surface 78 at the other end. By setting up a second oil groove channel connected to the side oil groove on the upper end surface of the slide plate, oil can be supplied to the side oil groove through the second oil groove channel, and combined with the first oil groove, oil can be supplied to the side oil groove through two oil grooves at the same time. It is also possible to supply oil to the side oil tank separately through the first or second oil tank, which is a preferred way of oil supply, which can realize the supply of high-pressure oil and generate the effect of high-pressure oil pressure, in order to reduce and pr...

Embodiment 3

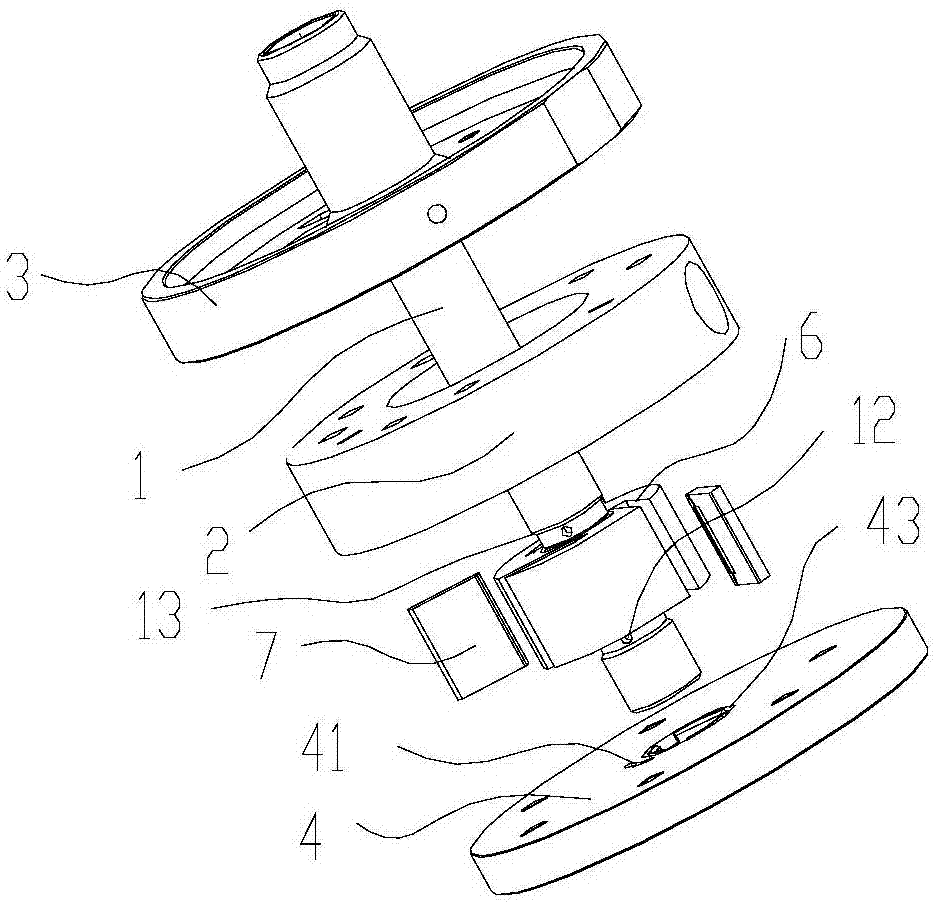

[0050] Such as Figure 3-7 As shown, the present invention also provides a rotary vane compressor, which includes: a main shaft 1; a cylinder 2; an upper flange 3; a lower flange 4; a cylinder cavity 5 formed between the main shaft 1 and the cylinder 2 between; sliding vane slot 6, which is opened on the main shaft 1 (preferably there are more than 3 sliding vane slots);

[0051] It also includes the aforementioned slide piece 7 (one slide piece 7 is correspondingly arranged in each slide piece groove 6), the slide piece is accommodated in each slide piece groove 6, and the first side 71 is located at the The upstream side of the rotation direction of the main shaft 1, the second side surface 72 is located on the downstream side of the rotation direction (such as Figure 8 As shown, the main shaft rotates clockwise, the upstream side of the rotation direction is the left side of the slide plate 7, and the downstream side of the rotation direction is the right side of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com