Cotton collecting device of disk bale plucker

A disc cotton catching machine and cotton hopper technology, applied in the direction of bale opening machines, etc., can solve the problems of reducing the friction between beaters and cotton raw materials, low grabbing efficiency, and affecting cotton bundle grabbing, etc., to achieve improved grabbing The effect of speed and gripping quality, improved gripping efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

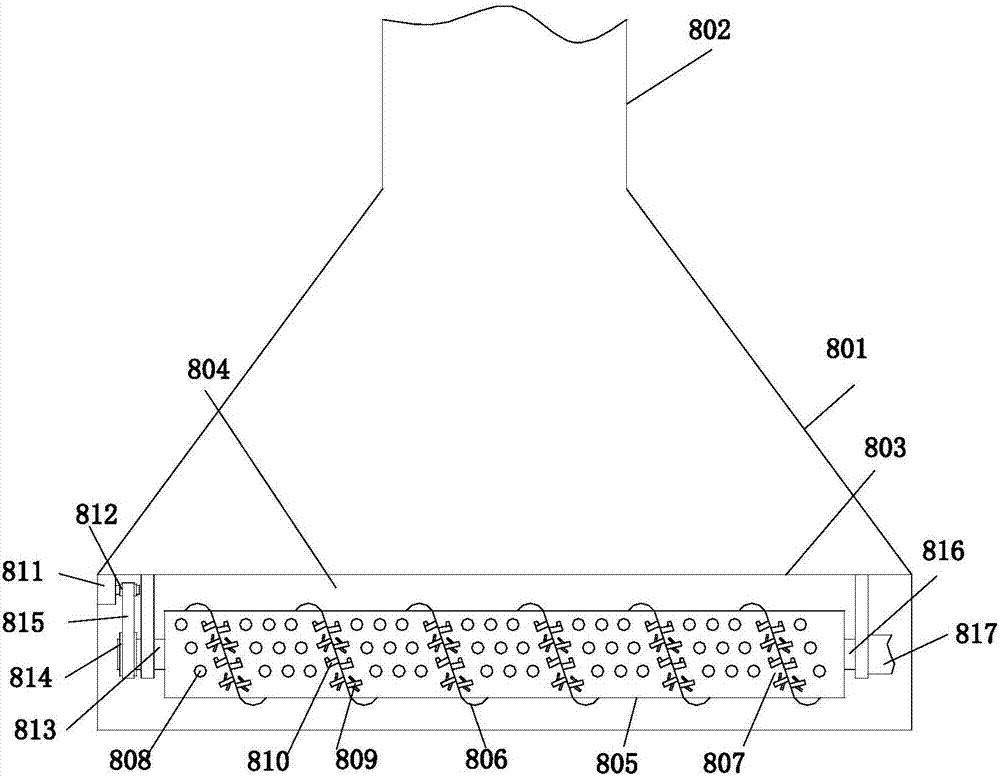

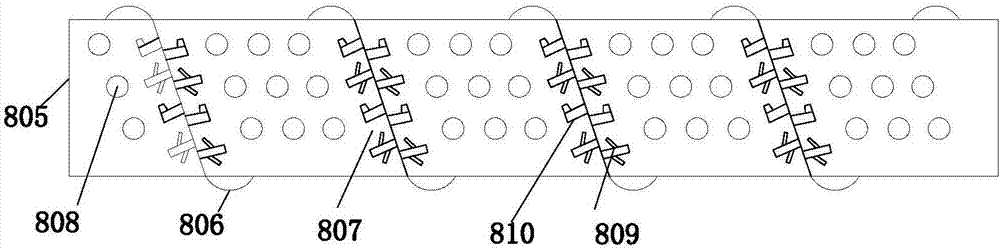

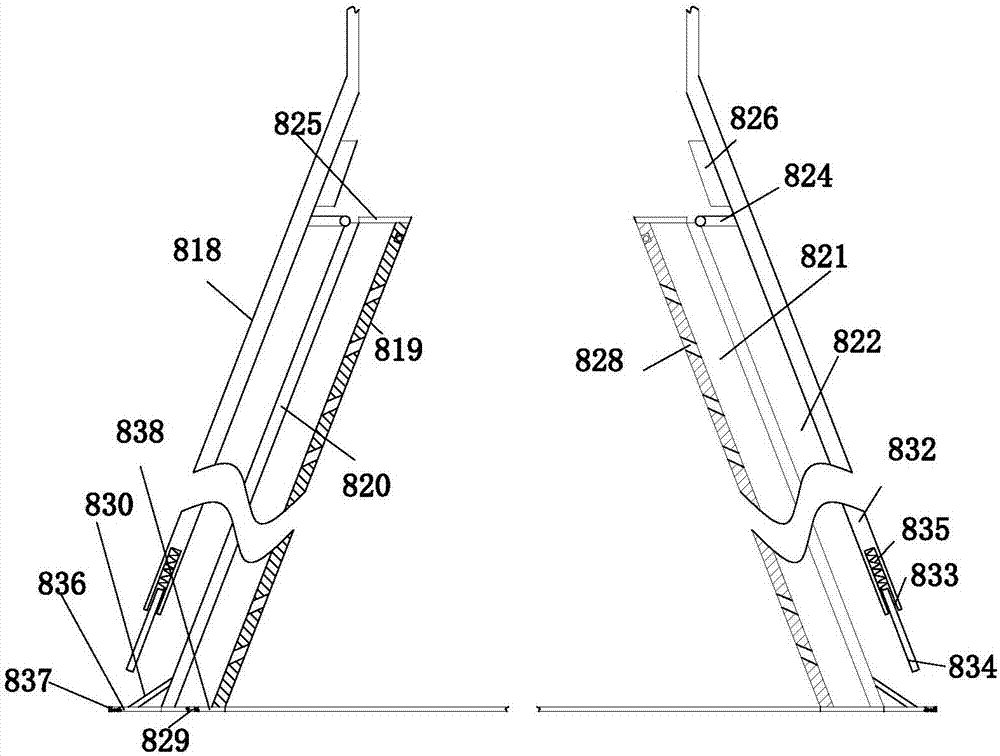

[0020] Example. A cotton receiving device of a disc catching machine, which is constituted as Figure 1 to Figure 6 As shown, it includes a cotton collection hopper 801, the upper end of the cotton collection hopper 801 is provided with a cotton delivery pipe 802, and the middle part below the cotton collection hopper 801 is provided with a beater mechanism 803; 804, the frame 804 is provided with a beater roller shaft 805 with a hollow structure, the surface of the beater roller shaft 805 is provided with a helical blade 806, the two side walls of the helical blade 806 are provided with blade groups 807, and the surface of the beater roller shaft 805 is also There is an air outlet hole 808 between the helical blades 806, and the air outlet hole 808 communicates with the hollow structure of the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com